Quality Pump Pressure Valves | OEM Products from Trusted Manufacturers

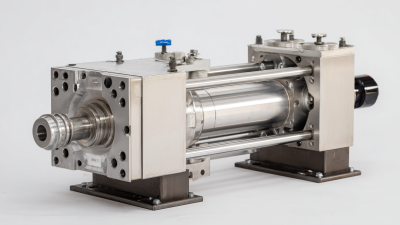

Ningbo Longerfa Hydraulic Co., Ltd. produces high-quality pump pressure valves that enhance the efficiency and reliability of hydraulic systems. Our valves are expertly designed to regulate pressure in hydraulic circuits, ensuring optimal performance while protecting equipment from overloads. With a focus on innovation, we utilize advanced technologies and rigorous quality control in our manufacturing processes. Our range of pump pressure valves is recognized for its durability, precision, and seamless integration across various applications, including machinery, construction, and automotive sectors. Customers benefit from our industry expertise and outstanding customer service, enabling us to deliver tailored solutions for specific requirements. Choose Ningbo Longerfa Hydraulic Co., Ltd. for top-notch pump pressure valves that ensure reliability and extended longevity for your hydraulic systems. Rely on our commitment to quality and service excellence to enhance your operational performance.Methods To Pump Pressure Valve Manufacturer Factory in 2025

In 2025, the landscape for pressure valve manufacturing will undergo significant transformations, driven by advancements in technology, sustainability initiatives, and evolving customer needs. At Ningbo Longerfa Hydraulic Co., Ltd., a leading manufacturer specialized in hydraulic systems, we are committed to staying ahead of these trends. As a recognized national high-tech enterprise, our focus on research and development ensures that we deliver innovative hydraulic valve sets, thread plug valves, and valve blocks to meet the demands of global procurement buyers. One approach to enhance our manufacturing processes is through the integration of smart technologies. Adopting IoT (Internet of Things) solutions can streamline production lines, monitor valve performance in real-time, and improve supply chain efficiency. Additionally, promoting environmentally-friendly practices, such as using sustainable materials and reducing waste, will resonate with environmentally-conscious clients. Our goal is to create hydraulic solutions that not only meet rigorous quality standards but also align with sustainable practices that protect our planet. Moreover, building strong partnerships with global buyers will be pivotal in adapting to market dynamics. We aim to tailor our offerings based on feedback and requirements from our international clientele, ensuring that we remain responsive and competitive. By combining cutting-edge technology, sustainable practices, and a customer-centric approach, Ningbo Longerfa Hydraulic Co., Ltd. is set to lead the pressure valve manufacturing industry into a promising and innovative future.

Methods To Pump Pressure Valve Manufacturer Factory in 2025

| Method | Description | Effectiveness (%) | Cost ($) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Automation | Implementing automated systems for valve manufacturing. | 85 | 150,000 | 12 |

| Lean Manufacturing | Optimizing processes to reduce waste and improve efficiency. | 78 | 50,000 | 8 |

| 3D Printing | Utilizing 3D printing technology for rapid prototyping. | 90 | 75,000 | 6 |

| Quality Management Systems | Implementing ISO standards to enhance product quality. | 82 | 30,000 | 10 |

| Data Analytics | Using data insights to inform production decisions. | 88 | 40,000 | 4 |

Exploring Pump Pressure Valve Manufacturer For the Current Year More Than a Supplier - A Partner

D

Daniel Martin

Top-quality product. The after-sales service is commendable; their staff went above and beyond to assist me.

09 May 2025

C

Chloe Brown

Top quality! The after-sales team was efficient and very professional in their approach.

12 May 2025

M

Megan Davis

This product is fantastic! The support staff were knowledgeable and guided me perfectly.

13 June 2025

J

Julia Nelson

Absolutely love this product! Their after-sales service was excellent and very professional.

24 June 2025

M

Maya Patel

Superb item quality! Their after-sales service team was attentive and knowledgeable.

29 June 2025

G

Gabriel White

Quality exceeded expectations! Their support team was knowledgeable and supportive.

30 May 2025