Pressure Relief Valve Testing | Top OEM Manufacturers & Reliable Products

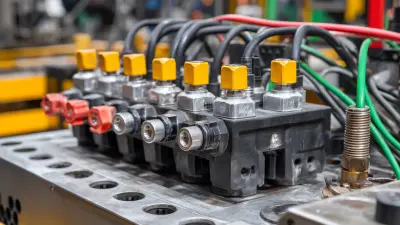

Ningbo Longerfa Hydraulic Co., Ltd. specializes in advanced testing solutions for pressure relief valves, ensuring maximum reliability and safety of hydraulic systems. Our modern testing facilities are equipped to verify that each valve complies with industry standards and operates effectively under diverse pressure conditions. With a strong focus on quality, our thorough evaluation process assesses key parameters such as flow rates, response times, and pressure settings. This meticulous approach guarantees the operational efficiency of every valve, essential for protecting both equipment and personnel. Serving a variety of industries, our testing services provide invaluable assurance that safety systems are fully operational. Trust Ningbo Longerfa Hydraulic Co., Ltd. for expert pressure relief valve testing to enhance the dependability of your hydraulic systems.Step-by-Step Guide To Pressure Relief Valve Testing Factory More Than a Supplier - A Partner From Concept to Delivery

At Ningbo Longerfa Hydraulic Co., Ltd., we go beyond the conventional role of a supplier; we strive to be an indispensable partner in the pressure relief valve testing process, supporting you from concept to delivery. As a national high-tech enterprise, our expertise in researching, developing, and manufacturing hydraulic products positions us uniquely to meet the needs of global buyers. We specialize in hydraulic valve sets, thread plug valves, valve blocks, and a range of hydraulic components designed for optimal performance and reliability. In our comprehensive step-by-step guide to pressure relief valve testing, we address the vital aspects that ensure your hydraulic systems operate efficiently and safely. Our dedicated team collaborates closely with you to understand your specific requirements, enabling us to develop tailored solutions that align with your project goals. Equipped with state-of-the-art technology and rigorous quality control measures, we ensure that every product we deliver passes stringent testing standards, thereby enhancing your operational efficiency and reducing downtime. Partnering with Ningbo Longerfa not only gives you access to high-quality hydraulic components but also a commitment to continuous improvement and innovation. We believe that fostering strong relationships with our clients leads to mutual success, and we are here to guide you through every step, ensuring that your hydraulic systems are equipped with the best solutions available in the market. Together, we can enhance the performance and reliability of your operations, paving the way for future advancements in your industry.

Step-by-Step Guide To Pressure Relief Valve Testing Factory More Than a Supplier - A Partner From Concept to Delivery

| Testing Phase | Description | Duration (Days) | Testing Equipment | Compliance Standards |

|---|---|---|---|---|

| Visual Inspection | Inspect physical condition and integrity of the valve. | 1 | Visual Inspection Tools | ASME/API Standards |

| Pressure Testing | Test valve for proper opening and closing pressure. | 2 | Hydraulic Pressure Test Equipment | ANSI/ASME |

| Leak Testing | Identify any leaks under specified pressure conditions. | 1 | Leak Test Equipment | ISO 5208 |

| Functional Testing | Verify the operational functionality under typical service conditions. | 3 | Functional Test Bench | API 527 |

| Final Documentation | Compile all test results and generate compliance documentation. | 1 | Documentation Software | Applicable Certification Standards |

Expert Tips For Pressure Relief Valve Testing Factory Service Service Backed by Expertise

S

Sarah Davis

This product has truly transformed my experience. The follow-up from their support team was both timely and informative.

29 June 2025

M

Megan Evans

The product has worked perfectly for me. The support provided post-purchase was knowledgeable and reliable.

12 June 2025

G

George Lee

Excellent quality overall! The support staff demonstrated true skill and professionalism in resolving my queries.

20 June 2025

Z

Zoe Scott

Really impressed with the quality! Their after-sales support was knowledgeable and friendly.

10 May 2025

C

Caleb Adams

High-quality product! Their customer service offered invaluable assistance during my purchase.

25 June 2025

G

Giselle Wood

High-quality purchase! The customer support was incredibly knowledgeable and efficient.

16 May 2025