Top OEM Pressure Control Valve Types from Leading Manufacturers & Trusted Factories

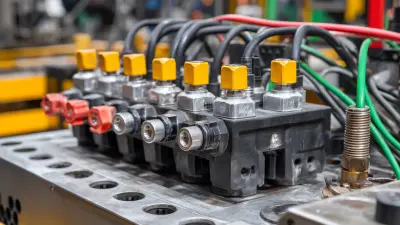

Ningbo Longerfa Hydraulic Co., Ltd. offers a wide range of pressure control valves designed for various industrial applications. Engineered for precise pressure regulation, our products enhance the efficiency and safety of hydraulic systems. Our selection includes relief valves, reducing valves, and sequence valves, each tailored to meet the specific needs of your operations. Made from high-quality materials, our valves are built for durability and reliable performance in challenging environments. Each product undergoes stringent testing to ensure compliance with international standards, guaranteeing peace of mind for users. Committed to innovation and customer satisfaction, Ningbo Longerfa Hydraulic Co., Ltd. strives to provide both standard options and customized solutions. Our expert team is available to assist in selecting the ideal pressure control valve to meet your requirements. Experience a combination of quality and advanced technology with our exceptional products.

Why Opt For Pressure Control Valve Types Factories Application Pioneers in the Field

Why Opt For Pressure Control Valve Types Factories Application Pioneers in the Field

| Valve Type | Application Field | Operating Pressure Range (psi) | Temperature Range (°F) | Material Used | Key Benefits |

|---|---|---|---|---|---|

| Globe Valve | Water Supply Systems | 50 - 150 | 32 - 120 | Cast Iron | High flow regulation |

| Ball Valve | Oil and Gas | 100 - 3000 | -20 - 200 | Stainless Steel | Quick operation |

| Check Valve | Pipelines | 10 - 500 | -40 - 150 | Brass | Prevents backflow |

| Pressure Relief Valve | Chemical Processing | 50 - 2000 | 32 - 180 | Alloy Steel | Safety and regulation |

| Solenoid Valve | Automation Systems | 0 - 150 | -10 - 80 | Plastic/Metal Hybrid | Remote operation |