Top Line Pressure Reducing Valve Manufacturers | OEM Products & Factories for Quality Solutions

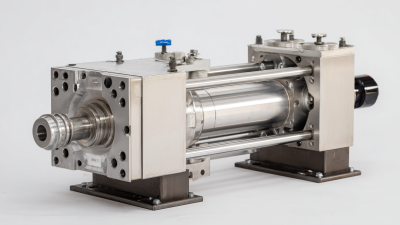

Ningbo Longerfa Hydraulic Co., Ltd. focuses on producing high-quality In Line Pressure Reducing Valves that ensure optimal pressure management in various hydraulic systems. These valves are designed to maintain a stable downstream pressure, enhancing the efficiency of machinery and equipment. Made from robust materials, they offer durability and reliability in demanding environments. With advanced technology and precision engineering, our valves deliver quick response times and excellent flow characteristics, making them ideal for applications in agriculture, construction, and manufacturing. Their easy installation and maintenance aim to improve system performance and lower operational costs. Rely on Ningbo Longerfa Hydraulic Co., Ltd. for innovative hydraulic solutions and elevate your system's performance with our cutting-edge In Line Pressure Reducing Valves.Why In Line Pressure Reducing Valve Manufacturer Guarantees Peak Performance Industry Giant

In the ever-evolving landscape of hydraulic components, the significance of choosing the right manufacturer cannot be overstated. Ningbo Longerfa Hydraulic Co., Ltd. stands out as a leading producer of hydraulic valve sets, thread plug valves, valve blocks, and various hydraulic products. As a national high-tech enterprise, we prioritize research and development to ensure our products not only meet but exceed industry standards. Our commitment to innovation is rooted in our understanding that reliable, high-performance hydraulic systems are essential for success across multiple sectors. One of the primary reasons global buyers trust us is our unwavering focus on peak performance. Our in-line pressure reducing valves are designed with precision, ensuring optimal functionality under pressure while maintaining operational efficiency. These valves offer crucial benefits such as enhanced durability, reduced maintenance times, and improved system stability. By partnering with Ningbo Longerfa, procurement agents gain access to technologically advanced solutions that facilitate better performance and reliability, ultimately contributing to their bottom line. Our dedicated team is on hand to support clients from initial inquiry through to post-purchase services. We understand the critical nature of hydraulic components in various applications and strive to forge lasting relationships with our clients through superior customer service and technical expertise. When you choose Ningbo Longerfa Hydraulic Co., Ltd., you're not just purchasing a product; you are investing in a promise of quality, reliability, and industry-leading performance.

Why In Line Pressure Reducing Valve Manufacturer Guarantees Peak Performance Industry Giant

| Feature | Description | Benefit | Industry Application |

|---|---|---|---|

| Stainless Steel Construction | Durable and corrosion-resistant materials. | Longer lifespan and reduced maintenance costs. | Oil & Gas, Chemical Processing |

| High Flow Capacity | Designed for maximum fluid flow efficiency. | Improved system efficiency and reduced energy consumption. | Water Treatment, HVAC |

| Precision Control | Accurate pressure regulation capabilities. | Enhances system reliability and safety. | Pharmaceuticals, Food & Beverage |

| Customizable Options | Tailored solutions to meet specific needs. | Increased compatibility with various systems. | Construction, Mining |

| Advanced Technology | Incorporates the latest advancements in pressure regulation. | Increased performance and lower failure rates. | Energy, Aerospace |

Comprehensive Comparison of In Line Pressure Reducing Valve Manufacturer in 2025 Factory-Direct Excellence

F

Frank Scott

This product has met all my expectations. The post-sale support was timely and very knowledgeable.

14 May 2025

J

John Martinez

High-quality product! The after-sales service was excellent, with staff who truly understand the product.

22 May 2025

E

Edward Hall

Great purchase! The product is exceptional, and their customer service was equally impressive.

10 June 2025

E

Ella White

Excellent item! The after-sales team was professional, ensuring all my questions were answered.

22 May 2025

A

Autumn Brown

Fantastic quality! Their support team is knowledgeable and available to assist anytime.

23 May 2025

L

Lucas Hill

Top-tier quality and service! Their support staff demonstrated real professionalism.

22 June 2025