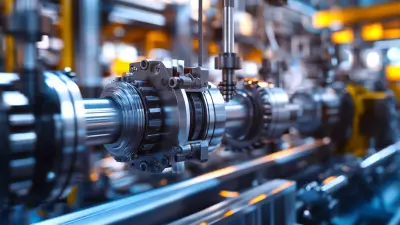

Top Hydraulic System Pressure Products from a Leading Manufacturer - High Quality & Reliability

Ningbo Longerfa Hydraulic Co., Ltd. specializes in high-quality hydraulic systems designed to optimize performance and efficiency across a variety of applications. Our advanced hydraulic components offer precise pressure control, ensuring reliable operation in demanding environments. Each component is engineered for durability and undergoes stringent testing to comply with international standards, giving clients confidence in their performance. We focus on customization to meet the unique needs of diverse industries, including construction and automotive sectors. Our dedicated expert team provides exceptional customer support and technical assistance, facilitating seamless integration and operation. Committed to advancing industry standards, Ningbo Longerfa Hydraulic Co., Ltd. combines cutting-edge technology with engineering excellence to deliver robust pressure management solutions tailored to specific requirements. Experience the impact of superior hydraulic components on your operations.10 tips Hydraulic System Pressure For the Current Year Factory

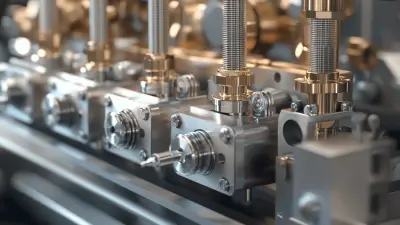

In the dynamic world of industrial manufacturing, maintaining optimal hydraulic system pressure is vital for efficiency and longevity. As you navigate this essential aspect in the current year, consider these ten tips to enhance your hydraulic systems effectively. First, regularly monitor and maintain your hydraulic fluid's temperature and cleanliness to prevent performance issues. Proper filtration is crucial to eliminate contaminants that can compromise system integrity. Secondly, ensure that all components, from Hydraulic Valve sets to plugs and blocks produced by reputable manufacturers like Ningbo Longerfa Hydraulic Co., Ltd., are correctly sized and compatible. This alignment prevents excessive wear and increases reliability. Regular inspections of hoses and fittings for leaks, wear, and tear will also help maintain pressure stability. Implementing a systematic maintenance schedule and utilizing advanced diagnostic tools can further enhance performance and preempt costly repairs. By focusing on these practices, you can optimize your hydraulic system's performance and prevent downtime. As a national high-tech enterprise, Ningbo Longerfa Hydraulic Co., Ltd. is dedicated to providing innovative hydraulic solutions that meet your operational needs, ensuring your systems are equipped for industry demands. Explore our extensive range of high-quality hydraulic components to bolster your production capabilities this year.

10 Tips Hydraulic System Pressure For the Current Year Factory

| Tip Number | Tip Description | Recommended Pressure (psi) | Notes |

|---|---|---|---|

| 1 | Regularly check fluid levels | 1500 | Low fluid can lead to pressure drops |

| 2 | Inspect seals and fittings | 2000 | Prevent leaks to maintain pressure |

| 3 | Monitor temperature | 1500 | High temps can affect pressure |

| 4 | Use quality hydraulic fluid | 1800 | Ensures optimal performance |

| 5 | Calibrate pressure gauges | 1600 | Accuracy is crucial for monitoring |

| 6 | Check for system contamination | 1750 | Contaminants can disrupt pressure |

| 7 | Test relief valves regularly | 1900 | Prevents excessive pressure build-up |

| 8 | Maintain hydraulic cylinders | 2000 | Ensure seals are intact |

| 9 | Train staff on system handling | 1600 | Improves safety and efficiency |

| 10 | Schedule regular maintenance | 1700 | Prevents major issues |

Proven Methods To Hydraulic System Pressure Service Backed by Expertise Industry Giant

J

James Thompson

The product quality exceeded my expectations. The support team was incredibly professional and responsive.

09 May 2025

S

Sarah Davis

This product has truly transformed my experience. The follow-up from their support team was both timely and informative.

29 June 2025

R

Rachel Scott

Superior product! The after-sales team was professional, friendly, and very reliable.

13 June 2025

J

Julia Nelson

Absolutely love this product! Their after-sales service was excellent and very professional.

24 June 2025

O

Owen Robinson

Top-notch product! The after-sales support was reliable and greatly appreciated.

04 June 2025

A

Aaron James

Top quality! The support team offered valuable insights and service post-purchase.

05 May 2025