Relief Valve Testing Requirements for Chinese Factories: Essential Guide to Key Products

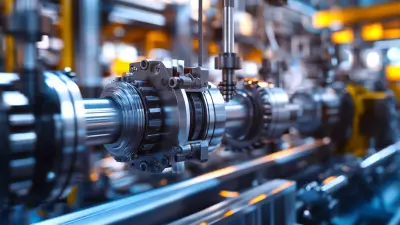

Ningbo Longerfa Hydraulic Co., Ltd. offers advanced relief valves engineered for optimal safety and efficiency in hydraulic systems. Our valves are rigorously tested to meet industry standards, ensuring dependable performance even under considerable pressure. This includes hydrostatic tests, leak tests, and thorough operational performance assessments to enhance durability and functionality. Each valve is meticulously crafted for precise pressure regulation, effectively preventing system overloads. We prioritize innovation by using cutting-edge technology and high-quality materials, making our products suitable for the most demanding applications. With a strong emphasis on customer satisfaction, our relief valves serve various sectors, including construction, manufacturing, and transportation. Ningbo Longerfa Hydraulic Co., Ltd. is committed to delivering high-quality hydraulic solutions, ensuring reliability and excellence in your operations.Practical Methods To Relief Valve Testing Requirements Factories Industry Leaders Ahead of the Curve

In today’s rapidly evolving industrial landscape, particularly in the hydraulic sector, ensuring compliance with stringent valve testing requirements is paramount for manufacturers. Ningbo Longerfa Hydraulic Co., Ltd., a recognized national high-tech enterprise, stands at the forefront of this challenge. Our commitment to innovation drives the development of rigorous testing protocols that not only meet but exceed industry standards. We understand that effective valve performance is critical for the safety and efficiency of hydraulic systems, which is why we have implemented practical methods that streamline testing processes without compromising quality. By utilizing advanced technology and engineering expertise, our team has designed a systematic approach to valve testing. Our methods encompass comprehensive analysis, real-time data monitoring, and feedback mechanisms that not only ensure compliance but also address potential issues before they arise. This proactive strategy positions us as a leader in the hydraulic components industry, enabling us to advance the interests of global procurement professionals seeking reliable and high-performing products. As we continue to innovate and optimize our testing methodologies, Ningbo Longerfa is not just keeping pace with industry standards; we are setting them. Our hydraulic valve sets, thread plug valves, and valve blocks are engineered to perform flawlessly under the most demanding conditions. Choosing Ningbo Longerfa means partnering with a manufacturer that prioritizes safety, reliability, and cutting-edge technology in hydraulic applications. Together, we can stay ahead of the curve in a competitive market.

Practical Methods To Relief Valve Testing Requirements Factories Industry Leaders Ahead of the Curve

| Testing Method | Industry Application | Frequency of Testing | Compliance Standards | Notes |

|---|---|---|---|---|

| Hydrostatic Testing | Oil and Gas | Annually | API 598 | High reliability requirement |

| Aerodynamic Testing | Aerospace | Before each flight | FAA Regulations | Critical for safety |

| Seat Tightness Testing | Chemical Processing | Semi-Annually | ASME B31.3 | Ensures leak prevention |

| Flow Capacity Testing | Water Treatment | Bi-Annually | ISO 5208 | Used in performance evaluations |

| Operational Testing | Power Generation | Monthly | IEEE Standards | Ensures system functionality |

Leading Chinese Relief Valve Testing Requirements Factories Delivers Unmatched Quality Market Leader

D

Daniel Martin

Top-quality product. The after-sales service is commendable; their staff went above and beyond to assist me.

09 May 2025

P

Patrick Wright

Impressive quality! The customer service was quick to assist and knowledgeable about the product.

25 June 2025

A

Avery Lee

The product quality is commendable! The follow-up service was very attentive and professional.

17 June 2025

W

Wyatt Edwards

The product quality is superb! Their after-sales service was prompt and professional.

18 June 2025

H

Henry Young

Outstanding product! Their support team was highly skilled and provided excellent assistance.

08 May 2025

S

Sienna Black

Amazing product! I was impressed not only with the quality but also with their customer service.

06 June 2025