High-Quality Testing Requirements for China Relief Valve Factories & Products

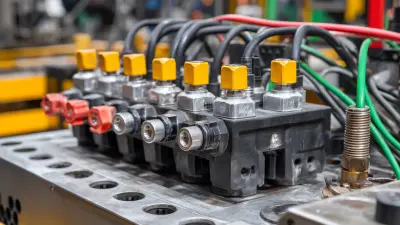

Ningbo Longerfa Hydraulic Co., Ltd. specializes in offering high-quality relief valves designed for optimal safety and performance in hydraulic systems. Our valves meet stringent testing requirements, ensuring reliability in various industrial applications. Each product undergoes extensive testing to adhere to top industry standards, providing excellent durability and efficiency. Engineered with advanced technology and premium materials, our relief valves accurately regulate pressure, safeguarding systems against overpressure and potential damage. Committed to innovation, we provide customized solutions tailored to meet the unique needs of our clients. Our expert team is dedicated to delivering exceptional customer support and ensuring the top performance of our hydraulic components. Choose Ningbo Longerfa Hydraulic Co., Ltd. for unmatched quality and reliability in relief valves.How To Evaluate ChinA Relief Valve Testing Requirements Factory-Direct Excellence Supplies the World’s Top Brands

Evaluating China relief valve testing requirements is crucial for global buyers seeking high-quality hydraulic components. As a national high-tech enterprise, Ningbo Longerfa Hydraulic Co., Ltd. stands at the forefront of this industry, manufacturing a comprehensive range of hydraulic products, including hydraulic valve sets, thread plug valves, valve blocks, and other hydraulic components. Our commitment to excellence ensures that we meet rigorous testing standards, helping you achieve reliability and performance in your applications. When sourcing hydraulic components, it's essential to understand the specific testing requirements applicable in China. These include adherence to international standards, rigorous quality control measures, and comprehensive testing procedures that guarantee product safety and efficacy. Longerfa’s adept R&D team continuously innovates to meet these standards, ensuring that our products not only fulfill but exceed the expectations of top global brands. By partnering with Longerfa, you gain access to factory-direct supplies that fuse advanced technology with trusted craftsmanship. Our streamlined operations allow us to cater to bulk orders efficiently, without compromising on quality. As the global demand for high-performance hydraulic components rises, we are poised to support your needs with reliable products that adhere to stringent testing requirements. Let us be your trusted supplier in navigating the complexities of hydraulic component procurement.

How To Evaluate China Relief Valve Testing Requirements

| Testing Requirement | Standard Applied | Frequency of Testing | Testing Equipment | Certification Required |

|---|---|---|---|---|

| Pressure Testing | API 526 | Annually | Hydraulic Test Bench | ISO 9001 |

| Functional Testing | API 598 | Quarterly | Test Owning System | CE Marking |

| Leak Testing | ASME BPVC | Semi-Annually | Mass Spectrometer | PED Compliance |

| Temperature Testing | ASTM ISO 6552 | Every 2 Years | Thermal Chamber | Certificate of Compliance |

why choose China Relief Valve Testing Requirements Your End-to-End Solution Industry Giant

J

Jessica Turner

I love this product! The support staff were incredibly knowledgeable and responsive, adding great value to my purchase.

25 June 2025

M

Megan Evans

The product has worked perfectly for me. The support provided post-purchase was knowledgeable and reliable.

12 June 2025

N

Natalie Green

Exceptional product quality! The support team offered knowledgeable and friendly assistance.

07 May 2025

E

Ella Harris

Wonderful product! The support staff demonstrated true professionalism and were very helpful.

09 June 2025

A

Avery Lee

The product quality is commendable! The follow-up service was very attentive and professional.

17 June 2025

H

Henry Young

Outstanding product! Their support team was highly skilled and provided excellent assistance.

08 May 2025