Top High-Quality Control Valve Manufacturers: Key Insights from Leading Factories

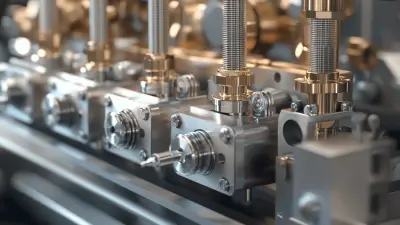

Control valves are essential for regulating fluid flow in various systems, ensuring optimal operation and efficiency. Ningbo Longerfa Hydraulic Co., Ltd. stands out as a reputable manufacturer of high-quality control valves designed for a range of industrial applications. Our advanced control valves facilitate precise management of pressure, temperature, and flow rate, making them suitable for the oil and gas, chemical processing, and water treatment sectors. Constructed from durable materials and incorporating cutting-edge technology, our products ensure reliability and longevity even in demanding environments. With an emphasis on quality and customer satisfaction, Ningbo Longerfa Hydraulic Co., Ltd. conducts rigorous testing to comply with international standards. Our experienced team is dedicated to providing customized solutions that meet specific client requirements, ensuring seamless integration into any system. Choose our control valves for dependable performance, backed by years of industry expertise.

Must-Know Tips For Working Of Control Valve Manufacturers Guarantees Peak Performance Service Backed by Expertise

Must-Know Tips For Working Of Control Valve Manufacturers Guarantees Peak Performance Service Backed by Expertise

| Tip | Description | Expert Recommendation | Expected Outcome |

|---|---|---|---|

| Regular Maintenance | Ensure valves are regularly serviced to prevent failure. | Schedule maintenance semi-annually. | Improved reliability and extended lifespan. |

| Proper Sizing | Select valves that fit the system requirements to avoid inefficiencies. | Consult with engineers during the selection process. | Enhanced system performance and energy savings. |

| Quality Assurance | Utilize valves from reputable manufacturers with QA certifications. | Request documentation during procurement. | Reduced risk of malfunctioning components. |

| Training Personnel | Ensure all operators are trained in valve operation and troubleshooting. | Implement a training program for staff. | Swift identification and resolution of issues. |

| Performance Monitoring | Track valve performance and respond to anomalies quickly. | Use monitoring software or systems. | Proactive maintenance and reduced downtime. |