OEM Valve Block Insights: Manufacturer Details & Best Product Choices Revealed

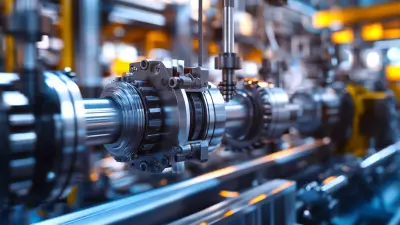

Ningbo Longerfa Hydraulic Co., Ltd. is a leading manufacturer in China, renowned for producing high-quality valve blocks that play a critical role in hydraulic systems. Designed with precision engineering, our valve blocks ensure efficient fluid control for heavy-duty applications requiring utmost reliability. As a national high-tech enterprise, we specialize in the research and development of a wide range of hydraulic products, including hydraulic valve sets and thread plug valves. Each component is crafted to meet rigorous quality standards, promising exceptional performance and durability. Our valve blocks are tailored to meet the diverse needs of industrial machinery and construction equipment, providing top-tier hydraulic solutions that enhance operational efficiency. Trust our expertise as a committed professional manufacturer dedicated to excellence in hydraulic technology.

10 tips valve block Service Backed by Expertise Manufacturers You Can Rely On

10 Tips for Valve Block Service Backed by Expertise Manufacturers You Can Rely On

| Tip Number | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Regularly inspect all valve components for wear and damage. | Extends the lifespan of the valve block. |

| 2 | Use manufacturer-recommended lubricants for maintenance. | Ensures optimal performance and reduces friction. |

| 3 | Calibrate valve settings according to specifications. | Enhances efficiency and accuracy of flow control. |

| 4 | Keep the operating environment free from contaminants. | Reduces the risk of valve failure and increases reliability. |

| 5 | Document all maintenance activities and any issues encountered. | Provides a valuable reference for future maintenance. |

| 6 | Train staff on proper handling and operation of valve blocks. | Minimizes human error and improves safety. |

| 7 | Perform routine pressure testing to check for leaks. | Identifies issues before they result in failures. |

| 8 | Replace any worn seals or gaskets promptly. | Ensures integrity and prevents leakage. |

| 9 | Seek immediate assistance from manufacturers for critical repairs. | Safeguards against further damage and operational downtime. |

| 10 | Stay updated with the latest technical information and maintenance techniques. | Improves overall service quality and knowledge of the valve systems. |