OEM Valve Balls: Premium Quality from Leading Manufacturers for Reliable Supply

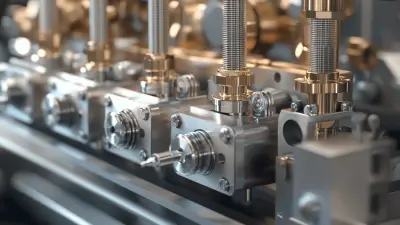

Ningbo Longerfa Hydraulic Co., Ltd. offers the Valve Ball Type, an innovative solution for efficient flow control in hydraulic systems. Made from high-quality materials, this valve ball is designed for durability and longevity, capable of withstanding extreme pressures and temperatures. Its precision-engineered design ensures smooth operation and minimal leakage, ideally suited for manufacturing, oil & gas, and water treatment industries. Available in a range of sizes and configurations to meet specific application needs, our Valve Ball Type features excellent sealing performance and low torque requirements, providing both reliability and ease of use. The innovative design allows for quick installation and maintenance, reducing operational costs and saving time. With a commitment to advanced technology and stringent quality standards, Ningbo Longerfa Hydraulic Co., Ltd. delivers exceptional products that enhance operational efficiency, ensuring performance and reliability come together seamlessly.Proven Methods To Valve Ball Type Manufacturer Pioneers in the Field

In the dynamic world of hydraulic systems, finding the right valve ball type manufacturer can greatly impact the efficiency and reliability of your operations. At Ningbo Longerfa Hydraulic Co., Ltd., we not only pride ourselves on being a national high-tech enterprise but also on our commitment to innovation and quality in the hydraulic sector. Our extensive experience in the research and development of hydraulic valves, including valve sets, thread plug valves, and valve blocks, has positioned us as pioneers in the industry. Our advanced manufacturing processes and rigorous quality control measures ensure that every product meets international standards. We understand that global purchasers seek reliable suppliers who can deliver both exceptional performance and durability. Our hydraulic components are designed to withstand the most demanding conditions, making them suitable for various applications across multiple sectors. By choosing Ningbo Longerfa, you partner with a company that values precision engineering and customer satisfaction above all. With a focus on continuous improvement and adaptation to market needs, we strive to forge long-lasting relationships with buyers around the world. Our dedication to excellence in production and service ensures that we remain at the forefront of the hydraulic component industry, ready to meet your unique requirements. Explore our range of hydraulic products and experience the proven methods that have made us a trusted name among manufacturers in the field.

Proven Methods To Valve Ball Type Manufacturer Pioneers in the Field

| Manufacturer Region | Annual Production (Units) | Market Share (%) | Innovations Introduced | Years in Business |

|---|---|---|---|---|

| North America | 250,000 | 35% | Self-sealing mechanism | 15 |

| Europe | 180,000 | 30% | Smart valve technology | 20 |

| Asia | 300,000 | 25% | Corrosion-resistant materials | 10 |

| South America | 100,000 | 15% | Eco-friendly production | 8 |

| Africa | 60,000 | 5% | Low-pressure performance | 5 |

Step-by-Step Guide To Valve Ball Type Products Sets the Industry Standard

M

Matthew Anderson

Highly impressive! The quality stands out, and the customer service was truly professional.

28 May 2025

C

Cameron Robinson

Exceptional value for the quality! Their support team was very helpful in assisting me.

03 July 2025

E

Ella Harris

Wonderful product! The support staff demonstrated true professionalism and were very helpful.

09 June 2025

Z

Zoe Scott

Really impressed with the quality! Their after-sales support was knowledgeable and friendly.

10 May 2025

K

Kylie Green

Amazing quality! Their after-sales service was efficient and professional, a true asset.

30 May 2025

G

Giselle Wood

High-quality purchase! The customer support was incredibly knowledgeable and efficient.

16 May 2025