Premium Overcenter Valves from Top OEM Manufacturers & Reliable Factories

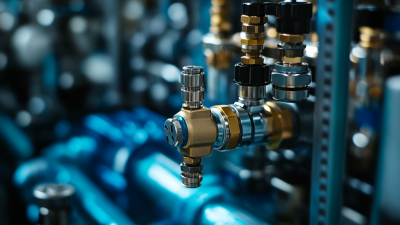

The Overcenter Valve from Ningbo Longerfa Hydraulic Co., Ltd. is engineered for superior hydraulic performance, playing a vital role in regulating fluid flow across various machinery applications. This precision valve is designed to enable effective maneuverability and operation of hydraulic systems, especially in mobile and industrial equipment. Its robust construction ensures stability and safety, effectively preventing unintended movements in hydraulic circuits. With a versatile design, the Overcenter Valve is adaptable to a wide range of applications, enhancing the efficiency of hydraulic systems in multiple sectors. Ningbo Longerfa is committed to innovation and quality, providing products that adhere to stringent industry standards. The Overcenter Valve exemplifies this dedication, ensuring durability and optimal performance even in challenging conditions, making it a reliable choice for enhancing hydraulic system functionality.10 tips Overcenter Valve Pioneers in the Field From Concept to Delivery

Title: 10 Tips for Overcenter Valve Pioneers in the Field From Concept to Delivery Overcenter valves serve as crucial components in hydraulic systems, allowing for controlled movement and load management in various applications. As a leader in hydraulic technology, Ningbo Longerfa Hydraulic Co., Ltd. offers valuable insights for global buyers seeking reliable and innovative overcenter valve solutions. Here are ten tips to consider when navigating from concept to delivery in this specialized field. First, understand the specific application of the overcenter valve within your hydraulic system. Identify the load requirements, pressure conditions, and environment where the valve will be utilized. Collaborating with experienced manufacturers like Ningbo Longerfa can provide insights into optimizing valve design tailored to your needs. Secondly, prioritize quality and compliance; working with a national high-tech enterprise ensures familiarity with international standards and ongoing innovations in hydraulic technologies. Finally, consider the importance of customer service and support. A strong partnership with a reliable manufacturer can streamline the delivery process and provide ongoing assistance for installation and maintenance. By focusing on these key aspects, global buyers can ensure they are equipped with the best overcenter valve solutions to enhance their hydraulic systems, driving efficiency and reliability in their operations.

10 Tips for Overcenter Valve Pioneers in the Field From Concept to Delivery

| Tip Number | Tip Description | Key Benefits | Implementation Example |

|---|---|---|---|

| 1 | Understand the Operational Environment | Increased reliability and longevity | Conduct field studies before design |

| 2 | Prioritize Ease of Maintenance | Reduced downtime | Design accessibility in key areas |

| 3 | Incorporate Feedback Loops | Continuous improvement in design | Use surveys post-installation |

| 4 | Evaluate Material Durability | Enhanced product safety | Conduct material stress tests |

| 5 | Focus on Ergonomic Design | Improved user satisfaction | Engage end-users in design phase |

| 6 | Utilize Advanced Simulation Technologies | Reduced prototyping costs | Employ CAD simulations |

| 7 | Implement Robust Testing Procedures | Ensure high quality standards | Conduct stress and fatigue tests |

| 8 | Engage in Cross-Disciplinary Collaboration | Enhanced innovation | Hold regular team workshops |

| 9 | Maintain Clear Documentation | Easier troubleshooting | Create a centralized documentation hub |

| 10 | Ensure Regulatory Compliance Early | Avoid costly redesigns | Review standards during initial design |

Best Way To Overcenter Valve Ahead of the Curve Manufacturers You Can Rely On

L

Linda Reynolds

I am extremely satisfied with the product. The customer service representatives were knowledgeable and very helpful.

11 May 2025

J

Julia Nelson

Absolutely love this product! Their after-sales service was excellent and very professional.

24 June 2025

V

Victoria Martin

I couldn’t be happier with this product! The follow-up service was top-notch and incredibly professional.

21 June 2025

J

Jack Lee

What a great purchase! The product quality is impressive, and the support team was very accommodating.

05 June 2025

H

Hailey Allen

I’m thoroughly impressed! The quality is remarkable, and the service team was friendly.

03 July 2025

N

Natalie Scott

Wonderful experience! The item quality and customer service made for a perfect transaction.

24 May 2025