OEM Pilot Operated Check Valves - Leading Manufacturers in China

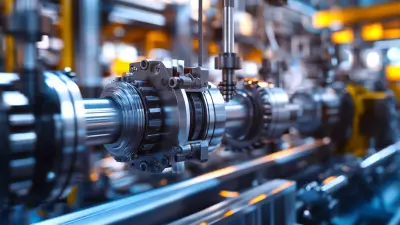

The OEM Pilot Operated Check Valve from Ningbo Longerfa Hydraulic Co., Ltd. is a highly advanced component specifically engineered for hydraulic systems that require precision and reliability. This valve facilitates unrestricted flow in one direction while effectively preventing reverse flow and back pressure, thus maintaining system integrity. Its pilot-operated feature ensures optimal control, making it well-suited for high-pressure environments. Crafted from robust materials, this check valve is built to last, delivering dependable performance even under challenging conditions. Customizable to cater to specific operational needs, it offers versatility across a range of industries, including construction, agriculture, and manufacturing. With a strong commitment to quality and innovation, Ningbo Longerfa Hydraulic Co., Ltd. provides superior hydraulic solutions. The Pilot Operated Check Valve enhances system designs and boosts safety and efficiency, making it a vital element for contemporary hydraulic applications.Key Methods For OEM Pilot Operated Check Valve Function Guarantees Peak Performance Market Leader

In the fast-evolving world of hydraulic systems, ensuring peak performance is not just a preference but a necessity. OEM Pilot Operated Check Valves are critical components that play a significant role in maintaining system integrity and efficiency. At Ningbo Longerfa Hydraulic Co., Ltd., we pride ourselves on being at the forefront of hydraulic innovation, dedicated to the research and development of products that meet the diverse needs of global buyers. Our team of experts has developed key methods to guarantee the performance of our pilot operated check valves. This involves rigorous testing and quality assurance that ensures each valve operates seamlessly under various conditions. As a national high-tech enterprise, we leverage advanced technology and industry best practices to position our products as market leaders. We focus on key criteria, such as response time, load handling capabilities, and durability, ensuring that our valves not only meet but exceed industry standards. By choosing Ningbo Longerfa, you’re not just purchasing hydraulic components; you’re investing in reliability and excellence. Our commitment to quality and innovation guarantees that you will experience superior functionality and safety in your hydraulic systems, allowing you to achieve operational excellence and drive business success. Partner with us to experience the difference in hydraulic solutions.

Key Methods For OEM Pilot Operated Check Valve Function Guarantees Peak Performance Market Leader

| Method | Description | Benefits | Application |

|---|---|---|---|

| Hydraulic Testing | Performing pressure tests to ensure valve integrity. | Ensures leak-free performance, verifying strength. | Industrial machinery, aerospace. |

| Material Selection | Choosing high-quality materials for durability. | Increases longevity and resistance to wear. | Automotive, oil and gas. |

| Precision Engineering | Utilizing CNC machining for accurate components. | Enhances fitting precision and function. | Manufacturing, robotics. |

| Quality Control | Implementing rigorous testing protocols for every batch. | Maintains consistent product quality and reliability. | General engineering, construction. |

| Field Testing | Testing valves in actual operating conditions. | Validates performance under real-world scenarios. | Waterworks, fire suppression systems. |

Best Options For OEM Pilot Operated Check Valve Function Your Trusted OEM Partner Now Trending

F

Frank Scott

This product has met all my expectations. The post-sale support was timely and very knowledgeable.

14 May 2025

A

Andrew Nelson

Superb quality! The follow-up service was remarkably good, demonstrating a commitment to customer care.

04 June 2025

S

Sarah Wilson

This is an excellent product! The customer service was attentive and provided great insights.

30 June 2025

M

Megan Davis

This product is fantastic! The support staff were knowledgeable and guided me perfectly.

13 June 2025

E

Emma Hernandez

I absolutely love this item! The care shown by customer service made my experience even better.

21 May 2025

L

Lucy Adams

Very happy with my decision! The quality is impressive, and customer support was outstanding.

08 May 2025