Top Mechanical Relief Valve Manufacturers and OEM Factory Products for Optimal Performance

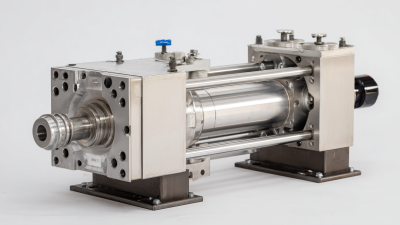

Ningbo Longerfa Hydraulic Co., Ltd. is dedicated to manufacturing high-quality mechanical relief valves that significantly enhance the safety and performance of hydraulic and pneumatic systems. These precision-engineered valves play a crucial role in regulating pressure and preventing equipment damage due to overpressure. Made from robust materials, our mechanical relief valves ensure exceptional reliability and longevity for diverse applications, including industrial machinery and automotive systems. We offer a variety of sizes and pressure settings to meet the specific needs of various industries. Committed to innovation and stringent quality control, each valve meets international standards, providing assurance and peace of mind for our customers. Our user-friendly design facilitates easy installation and maintenance, further improving system efficiency. Rely on Ningbo Longerfa Hydraulic Co., Ltd. for premium mechanical relief valves that contribute to optimal performance and safety throughout your operational processes.10 Essential Tips For Mechanical Relief Valve Manufacturers Now Trending Industry Giant

In the competitive landscape of hydraulic products, mechanical relief valve manufacturers must adopt strategies that ensure their relevance in a rapidly evolving industry. Ningbo Longerfa Hydraulic Co., Ltd., a distinguished player recognized as a national high-tech enterprise, offers invaluable insights for businesses looking to enhance their operations and reach a global audience. Firstly, collaboration with research and development teams is crucial. By continuously innovating and improving existing products, manufacturers can meet the changing needs of their customers. This includes investing in advanced technologies and adopting best practices for production efficiency. Secondly, establishing a robust supply chain is essential. Working with reliable suppliers and distributing partners enables manufacturers to ensure timely deliveries and maintain the quality that clients expect. Moreover, leveraging online platforms and digital marketing strategies allows manufacturers to broaden their reach. Engaging content and targeted advertising not only boost visibility but also foster relationships with potential buyers worldwide. Finally, prioritizing customer feedback and aligning product development with market demands is key. Manufacturers like Longerfa Hydraulic can thrive in this dynamic marketplace by focusing on quality, innovation, and customer satisfaction.

10 Essential Tips For Mechanical Relief Valve Manufacturers Now Trending Industry Giant

| Tip Number | Tip Description | Expected Impact | Industry Insight |

|---|---|---|---|

| 1 | Implement Smart Manufacturing Techniques | Increased efficiency and reduced waste | Focus on IoT integration |

| 2 | Enhance Product Testing Procedures | Higher reliability and customer trust | Focus on real-world simulations |

| 3 | Utilize Advanced Materials | Durability and resistance to corrosion | Incorporate composites and alloys |

| 4 | Focus on Customization | Meeting diverse customer needs | Adopt modular designs |

| 5 | Enhance Supply Chain Collaboration | Streamlined processes and cost savings | Utilize technology for communication |

| 6 | Prioritize Safety Standards | Minimized risks and improved compliance | Regular training and certifications |

| 7 | Embrace Digital Transformation | Improved data management and analytics | Use of cloud solutions |

| 8 | Streamline Production Processes | Reduced lead times and costs | Lean manufacturing principles |

| 9 | Invest in Employee Training | Enhanced skills and productivity | Regular workshops and seminars |

| 10 | Engage with Industry Trends | Staying competitive and innovative | Follow market research and reports |

Best Strategies For Mechanical Relief Valve Manufacturers Global Reach Delivers Unmatched Quality

J

James Thompson

The product quality exceeded my expectations. The support team was incredibly professional and responsive.

09 May 2025

G

George Lee

Excellent quality overall! The support staff demonstrated true skill and professionalism in resolving my queries.

20 June 2025

N

Natalie Green

Exceptional product quality! The support team offered knowledgeable and friendly assistance.

07 May 2025

E

Eric Turner

Top-notch product! Their customer service staff were incredibly professional and efficient.

05 June 2025

Z

Zoe Scott

Really impressed with the quality! Their after-sales support was knowledgeable and friendly.

10 May 2025

L

Leah Thompson

Love this product! Their after-sales service was friendly and highly professional.

25 May 2025