Top Manufacturers of High-Quality Flow Control Valves and Their Best Products

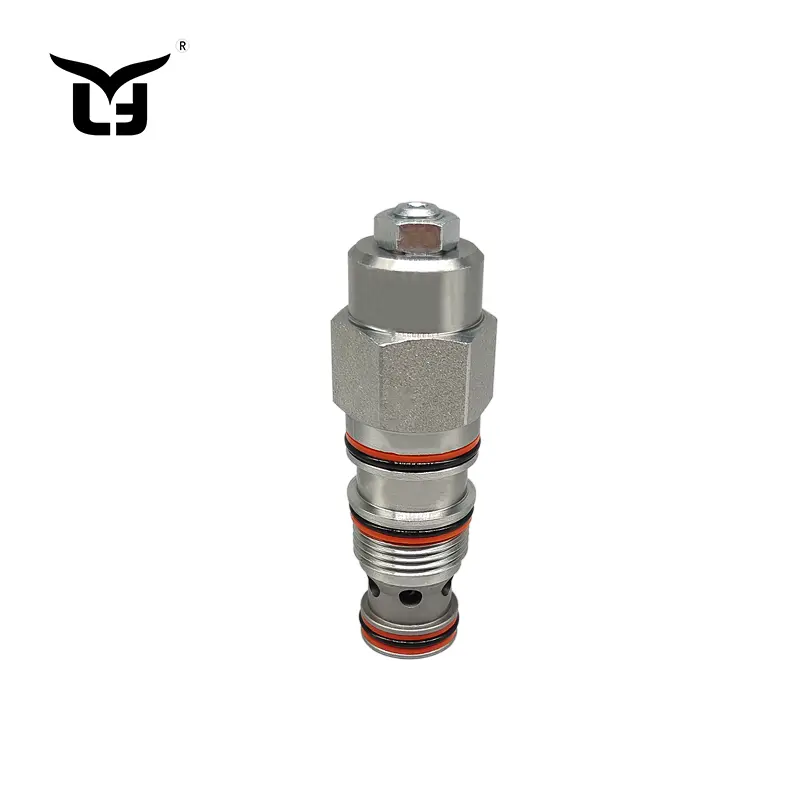

The Flow Control Valve from Ningbo Longerfa Hydraulic Co., Ltd. is engineered to enhance fluid flow regulation within hydraulic systems. Known for its sturdy design and dependability, this valve provides precise control over fluid dynamics, ensuring peak performance and efficiency across a range of applications. Constructed from high-quality materials, it ensures durability and resistance to wear, making it ideal for harsh conditions. With smooth operation and easy flow rate adjustments, it effectively maintains desired pressure levels in hydraulic circuits. Ningbo Longerfa Hydraulic Co., Ltd. merges cutting-edge engineering with innovative technology to produce products that adhere to the highest safety and performance standards. Whether utilized in industrial machinery, automotive systems, or diverse hydraulic applications, the Flow Control Valve is crucial for improving functionality and reliability. Rely on our specialized expertise for solutions that optimize your systems' operational efficiency.Tips & Tricks for Flow Control Valve Direction Products Guarantees Peak Performance

Flow control valves play a critical role in hydraulic systems, ensuring optimal performance and efficiency across various industrial applications. At Ningbo Longerfa Hydraulic Co., Ltd., we understand that the right flow control valve direction products can make a significant difference in maintaining peak system performance. Here are some essential tips and tricks for selecting the best products to meet your operational needs. First, consider the specific requirements of your hydraulic system. Different applications may demand unique flow characteristics, pressure ratings, and responsiveness. Our extensive range of hydraulic valve sets and components is designed to cater to diverse environments, ensuring reliability and efficiency. Conduct thorough research on the specifications and capabilities of each product to identify the perfect match for your system. Additionally, maintaining your flow control valves is crucial for sustained performance. Regular inspections and timely maintenance can prevent malfunction and extend the lifespan of your equipment. By investing in high-quality products from a trusted manufacturer like Longerfa, you can minimize downtime and ensure your hydraulic systems operate at their best. Trust our expertise as a national high-tech enterprise dedicated to innovation in the hydraulic industry. With our commitment to quality and performance, we are here to support your business in achieving operational excellence.

Tips & Tricks for Flow Control Valve Direction Products Guarantees Peak Performance

| Tip | Description | Expected Outcome |

|---|---|---|

| Regular Maintenance | Perform regular checks and maintenance on valves to ensure they are operating correctly. | Increased lifespan and reliability of flow control valves. |

| Correct Sizing | Ensure the valve size matches the requirements of the application. Oversized or undersized valves can lead to inefficiencies. | Improved system efficiency and reduced energy costs. |

| Proper Installation | Follow manufacturer guidelines for installation to avoid improper functioning. | Optimal performance and minimal risk of failure. |

| Quality Fluid Monitoring | Monitor and control the quality of fluids passed through the valve. | Reduction in wear and tear, prolonged valve lifespan. |

| Training for Operators | Provide adequate training for personnel on proper valve operation techniques. | Minimized operational errors and enhanced safety. |

Pinpointing Flow Control Valve Direction Manufacturers You Can Rely On Outperforms the Competition

C

Cynthia Johnson

I truly appreciate the quality and care in customer service. The team was really helpful when I had questions.

16 May 2025

A

Alice Green

A fantastic item! The after-sales service team were well-trained and very helpful with everything I needed.

08 June 2025

J

Jacob Wilson

Impressive all around! The quality is great, and the after-sales support was very helpful.

25 May 2025

E

Ella White

Excellent item! The after-sales team was professional, ensuring all my questions were answered.

22 May 2025

G

Gavin Martinez

Thrilled with the product! The customer service team has been exceptionally helpful.

29 May 2025

S

Samuel Walker

Great purchase! Both item quality and customer service have impressed me greatly.

18 May 2025