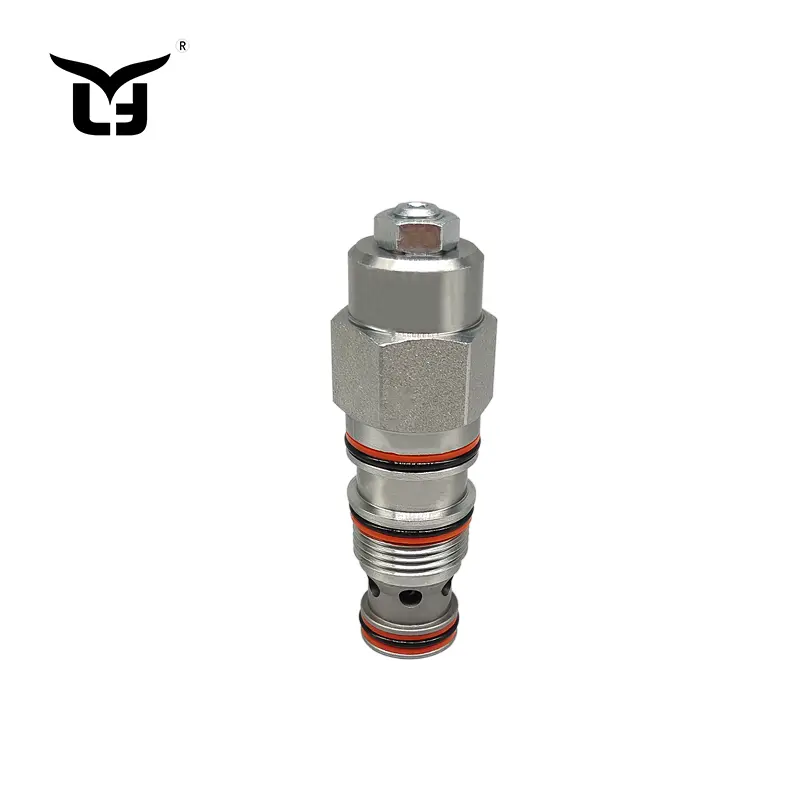

High-Quality OEM Cartridge Flow Control Valves | Leading Manufacturers & Suppliers

The Cartridge Flow Control Valve from Ningbo Longerfa Hydraulic Co., Ltd. is a key element for enhancing fluid control in hydraulic systems. Engineered for precision, this valve enables accurate flow regulation, significantly improving efficiency and overall performance in a variety of applications. Its durable construction is designed to endure high pressures, making it ideal for challenging industrial settings. With a compact design, it easily integrates into existing systems while minimizing space requirements. The valve's adjustable flow settings offer users the ability to tailor performance to meet specific operational demands. Compatible with a diverse range of hydraulic fluids, this valve showcases versatility and adaptability. Ningbo Longerfa Hydraulic Co., Ltd. is dedicated to providing premium hydraulic solutions, and this flow control valve exemplifies their commitment to quality and reliability, ensuring enhanced efficiency in hydraulic systems.10 tips Cartridge Flow Control Valve Manufacturers Is The Best For the Current Year

In the competitive landscape of hydraulic systems, selecting the right cartridge flow control valve manufacturer is essential for ensuring optimal performance and reliability. Ningbo Longerfa Hydraulic Co., Ltd., a national high-tech enterprise, stands out in this arena through its dedication to research and development, and its commitment to quality in production. Our comprehensive range includes hydraulic valve sets, thread plug valves, and valve blocks, specifically tailored to meet the diverse needs of global buyers. The top ten tips for choosing the best cartridge flow control valve manufacturer revolve around critical factors that can significantly impact the efficiency of hydraulic systems. Firstly, assess the manufacturer’s reputation; a company like Ningbo Longerfa, known for its advanced technological capabilities and high-quality products, should be at the top of your list. Secondly, consider their R&D investment, as this reflects the manufacturer’s ability to innovate and improve product offerings over time. Moreover, certifications and compliance with international standards should not be overlooked, ensuring that the products adhere to the highest safety and performance benchmarks. Finally, effective communication and customer support are crucial; a responsive manufacturer can provide invaluable assistance in customizing solutions that meet your specific operational needs. By prioritizing these factors, you can make informed decisions that will ultimately enhance the efficiency and reliability of your hydraulic systems.

10 Tips Cartridge Flow Control Valve Manufacturers Is The Best For the Current Year

| Tip Number | Tip Description | Key Benefit | Recommended Action |

|---|---|---|---|

| 1 | Choose a reputable manufacturer | Ensures product reliability | Research and verify credentials |

| 2 | Inspect quality certifications | Assures quality control | Request documentation |

| 3 | Evaluate customer support | Enhances user experience | Test their responsiveness |

| 4 | Analyze product range | Offers tailored solutions | Review product offerings |

| 5 | Assess technological advancements | Improves efficiency and performance | Inquire about innovations |

| 6 | Check for warranty and service terms | Protects investment | Review terms thoroughly |

| 7 | Look for customization options | Meets specific needs | Discuss your requirements |

| 8 | Evaluate pricing structures | Ensures budget compliance | Request detailed quotes |

| 9 | Research client testimonials | Gains insights into reliability | Read reviews and case studies |

| 10 | Check industry recognition and awards | Confirms market position | Look for certifications |

Why Cartridge Flow Control Valve Manufacturers Outperforms the Competition Exceeds Industry Benchmarks

K

Kevin Perez

Excellent craftsmanship! The follow-up service was superb, showcasing a true commitment to customer satisfaction.

26 June 2025

M

Michelle Clark

Fantastic item! The after-sales service was helpful, and the representatives were very knowledgeable.

09 June 2025

T

Tyler King

Thrilled with the quality! The customer service was fantastic—always ready to help!

06 May 2025

R

Rachel Scott

Superior product! The after-sales team was professional, friendly, and very reliable.

13 June 2025

J

Julia Nelson

Absolutely love this product! Their after-sales service was excellent and very professional.

24 June 2025

C

Cameron Robinson

Exceptional value for the quality! Their support team was very helpful in assisting me.

03 July 2025