In today's industrial landscape, efficiency is paramount, and the choice of components plays a crucial role in achieving operational excellence. One such component gaining traction is the Unidirectional Throttle Valves. These valves, designed to regulate fluid flow in a single direction, offer significant advantages over traditional throttling mechanisms, particularly in terms of energy conservation and system reliability. By effectively managing flow dynamics, Unidirectional Throttle Valves not only minimize pressure losses but also enhance the longevity of equipment through reduced wear and tear.

This blog will delve into the multiple benefits these innovative valves provide, offering practical tips for integration in various industrial applications. Whether you're looking to streamline processes, lower operational costs, or enhance system performance, understanding the role of Unidirectional Throttle Valves is essential for unlocking efficiency in your operations.

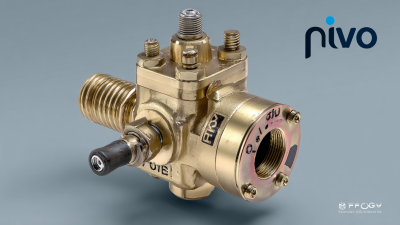

In the quest for enhanced industrial efficiency, unidirectional throttle valves play a crucial role. These valves control fluid flow in a single direction, allowing for smoother operations and preventing backflow, which can disrupt production processes. Their ability to stabilize pressure and regulate flow rates leads to improved system performance and reduced energy consumption. As industries seek to optimize their operations, the implementation of unidirectional throttle valves becomes an essential strategy.

**Tip:** When selecting unidirectional throttle valves for your system, consider the specific flow characteristics and pressure requirements of your application. Proper sizing and material selection can significantly influence the performance and longevity of the valve in your industrial setup.

Moreover, unidirectional throttle valves enhance safety by ensuring that fluids only move in designated pathways, minimizing the risk of system failures and leaks. Their robust design contributes to the reliability of industrial equipment, ultimately leading to lower maintenance costs and downtime.

**Tip:** Regular maintenance and inspection of unidirectional throttle valves are vital. Establish a routine check to ensure all components are functioning as intended, which will help prolong the life of the valves and the overall system efficiency.

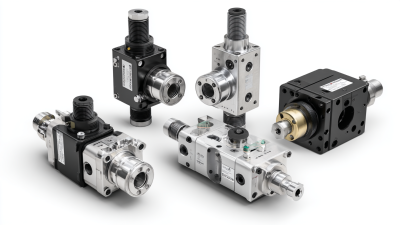

When selecting throttle valves for industrial applications, understanding the nuances between unidirectional and bidirectional designs is crucial. Unidirectional throttle valves allow fluid flow in a single direction, which optimizes performance by reducing resistance and ensuring consistent pressure regulation. This streamlined flow path minimizes turbulence and energy loss, leading to enhanced system efficiency. Additionally, unidirectional valves are often simpler in construction, making them easier to maintain and install, which can result in lower operational costs for manufacturers.

On the other hand, bidirectional throttle valves offer greater versatility by allowing flow in both directions. While this dual functionality can be advantageous in certain applications, it may introduce complexity in control mechanisms and potential pressure fluctuations. The increased turbulence in a bidirectional system can lead to inefficiencies, especially in high-performance environments where precision is key. Therefore, for applications where space and efficiency are paramount, unidirectional throttle valves emerge as a superior choice, aligning with current industry demands for enhanced productivity and reliability.

In today's fast-paced industrial landscape, efficiency is paramount, and unidirectional throttle valves are gaining traction as a pivotal component in manufacturing processes. These valves are designed to regulate fluid flow in a singular direction, which significantly enhances system performance. One of the key benefits of implementing unidirectional throttle valves is their ability to offer precise control over flow rates. This precision helps optimize the performance of machinery, ensuring that operations run smoothly and reducing the risk of mechanical failure due to improper flow management.

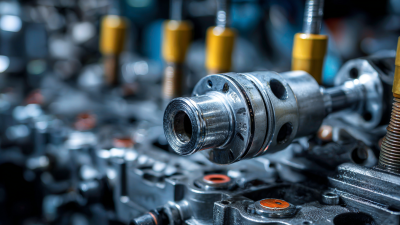

Moreover, unidirectional throttle valves contribute to energy savings by minimizing energy loss associated with backflow. Traditional flow control mechanisms often experience inefficiencies due to the fluctuating directions of fluid flow, leading to wasted resources. By maintaining a consistent flow direction, these valves ensure that energy consumption is kept in check, ultimately lowering operational costs. Additionally, their robust design translates to reduced maintenance needs, as they are less prone to wear and tear compared to their bi-directional counterparts. As such, integrating unidirectional throttle valves into industrial applications not only streamlines processes but also fortifies the overall reliability of manufacturing systems.

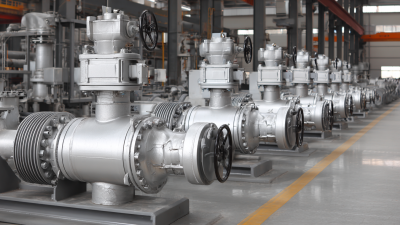

Unidirectional throttle valves are increasingly becoming essential components across various industrial applications due to their efficiency and performance benefits. In hydraulic systems, these valves ensure precise flow control in a single direction, which can enhance the overall speed and responsiveness of machinery. For example, in construction equipment such as excavators, unidirectional throttle valves provide controlled descent of booms and attachments, ensuring both safety and operational efficiency.

Moreover, in the automotive industry, unidirectional throttle valves play a crucial role in air intake systems, optimizing engine performance while minimizing emissions. Their ability to facilitate smooth airflow in one direction allows for better fuel efficiency and dynamics, paving the way for greener technologies. In food processing, unidirectional throttle valves help maintain consistent fluid flow rates, crucial for maintaining the quality and safety of food products. These valves, thus, are not only pivotal in enhancing productivity but also in adhering to safety and regulatory standards across various sectors.

Recent innovations in unidirectional throttle valve technology are poised to revolutionize industrial processes, enhancing efficiency and reliability across various sectors. According to a market analysis by Research and Markets, the global throttle valve market is projected to reach $5.7 billion by 2025, growing at a CAGR of 4.6%. This growth underscores the importance of advanced technologies, including the adoption of smart valves that leverage IoT for real-time monitoring and control, facilitating optimal performance in applications that demand precision.

One of the most significant future trends is the integration of AI and machine learning algorithms that can adaptively adjust valve settings based on system demands and environmental conditions. This level of responsiveness not only minimizes energy consumption but also extends the lifespan of the equipment. A study published by the International Society of Automation suggests that implementing smart unidirectional throttle valves could lead to a 20% reduction in energy costs in large-scale industrial setups. As these technologies continue to develop, the potential for increased automation and improved process control will undoubtedly position unidirectional throttle valves as essential components in future industrial applications.

| Feature | Traditional Throttle Valves | Unidirectional Throttle Valves | Future Innovations |

|---|---|---|---|

| Flow Control Precision | Moderate | High | Adaptive Algorithms |

| Maintenance Requirements | High | Low | Self-diagnostic Systems |

| Energy Efficiency | Lower | Higher | Smart Energy Management |

| Response Time | Slow | Fast | Real-time Adjustments |

| Operational Range | Limited | Extended | Wide Operational Spectrum |