In the rapidly evolving industrial landscape, the performance of Remote Control Relief Valves (RCRVs) is critical for maintaining safety and efficiency in various applications, from petrochemical plants to power generation facilities. According to a recent industry report by MarketsandMarkets, the global market for relief valves is projected to reach USD 6.9 billion by 2025, highlighting the growing demand for advanced valve technologies. This surge emphasizes the necessity for innovative approaches to enhance the reliability and responsiveness of RCRVs. By adopting state-of-the-art technologies such as IoT integration, predictive maintenance, and adaptive control systems, industries can significantly improve operational performance. This blog will explore the various innovative strategies employed to compare and enhance RCRV functionality, ensuring they meet the rigorous demands of modern industrial environments while also adhering to stringent safety standards.

In the rapidly evolving industrial landscape, the performance of Remote Control Relief Valves (RCRVs) is critical for maintaining safety and efficiency in various applications, from petrochemical plants to power generation facilities. According to a recent industry report by MarketsandMarkets, the global market for relief valves is projected to reach USD 6.9 billion by 2025, highlighting the growing demand for advanced valve technologies. This surge emphasizes the necessity for innovative approaches to enhance the reliability and responsiveness of RCRVs. By adopting state-of-the-art technologies such as IoT integration, predictive maintenance, and adaptive control systems, industries can significantly improve operational performance. This blog will explore the various innovative strategies employed to compare and enhance RCRV functionality, ensuring they meet the rigorous demands of modern industrial environments while also adhering to stringent safety standards.

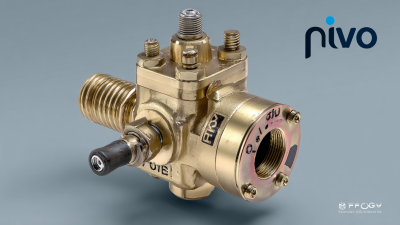

Remote control relief valves play a critical role in maintaining safety and efficiency across various industrial applications. These valves operate by automatically releasing excess pressure, protecting equipment and processes from potential damage. Understanding the key principles of their functionality is essential for optimizing their performance. Factors such as valve sizing, actuator response time, and maintenance schedules directly influence how effectively these valves operate under different conditions.

Tip: Regular calibration of remote control relief valves ensures their responsiveness, especially in environments with fluctuating pressures. Scheduled testing can identify any mechanical wear that could compromise valve performance.

Another crucial aspect is the selection of appropriate materials and designs that can withstand the specific conditions of the industrial setting, including temperature fluctuations and corrosive substances. By carefully considering these elements, companies can enhance the reliability of their relief valves, reducing downtime and maintenance costs.

Tip: Invest in training for operational staff to recognize warning signs of valve malfunction. Familiarity with the equipment not only promotes safe operations but also contributes to a proactive maintenance approach.

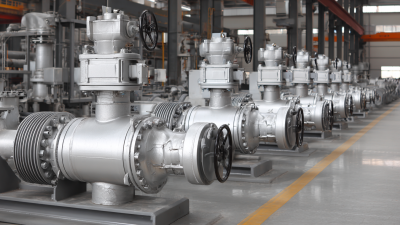

The optimization of remote control relief valve performance presents several critical challenges in industrial settings, particularly given the increasing complexity of modern processes. According to a report by the International Society of Automation, nearly 60% of industries reported difficulties in maintaining consistent operational efficiency due to valve malfunction and erratic performance. These issues often stem from factors such as wear and tear, environmental conditions, and improper calibration, all of which can significantly affect the valve's responsiveness.

Furthermore, data from the American Society of Mechanical Engineers indicates that failure to address these challenges can lead to operational inefficiencies, resulting in downtime costs averaging $250,000 per hour in manufacturing industries. Effective performance optimization requires embracing advanced technologies, such as predictive analytics and real-time monitoring systems. Investing in these solutions can help in identifying potential failures before they occur, ensuring smoother operation and enhanced reliability of remote control relief valves. By focusing on these innovative strategies, industries can better navigate the complexities associated with valve performance, ultimately leading to improved safety and productivity.

In the ever-evolving industrial landscape, the implementation of innovative technologies for real-time performance monitoring of remote control relief valves is proving to be a game-changer. According to a recent report by the Markets and Markets Research, the global adoption of smart monitoring solutions in industrial settings is projected to grow by 20% over the next five years. These advancements not only enhance operational efficiency but also significantly reduce the chances of system failures, resulting in substantial cost savings.

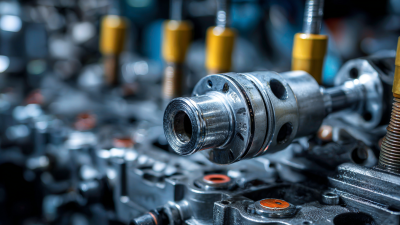

Integrating advanced sensor technologies and IoT connectivity allows for continuous performance feedback, enabling operators to make informed decisions promptly. For instance, predictive analytics can forecast potential valve malfunctions before they occur, thereby preventing unplanned downtimes. Tips for enhancing remote control valve performance include routinely calibrating sensors to ensure accuracy and implementing a centralized monitoring system to consolidate performance data for quicker analysis.

Another innovative approach involves utilizing machine learning algorithms to refine system responses based on historical performance data. By analyzing patterns, industries can adjust their operational parameters in real-time, leading to improved safety and efficiency. Maintenance teams should regularly review these analytics and adapt practices accordingly to maximize the longevity and reliability of the remote control systems, ensuring that they meet both current and future demands in industrial applications.

When it comes to maintaining relief valves in industrial applications, understanding their intricate components and functioning is essential. Regular inspections can significantly reduce the likelihood of unexpected failures. It’s crucial to check the seat and disc for signs of wear, as any deformities can compromise the valve's ability to close properly. Additionally, keep an eye on the actuator and control mechanisms to ensure they are not only operational but also responsive to system demands.

**Tips:** Implement a routine maintenance schedule that includes checking the valve settings and pressures. Pay attention to the manufacturer's guidelines for specific maintenance intervals, as varying environments can influence wear and tear.

Another vital aspect is troubleshooting issues promptly. If a relief valve is not operating as expected, start by identifying any possible blockages in the inlet or outlet, as these could impede performance. Utilizing advanced diagnostic tools can help pinpoint exact problems, making for a more efficient troubleshooting process.

**Tips:** When replacing components, always ensure that you are using parts that meet or exceed the original specifications. This practice not only enhances the reliability of your valve but also ensures compliance with safety standards and regulations.

| Dimension | Description | Best Practice | Troubleshooting Tip |

|---|---|---|---|

| Pressure Settings | Relief valves should be set to open at the correct pressure to prevent system overpressure. | Regularly verify and adjust pressure settings based on system demands. | If the valve opens prematurely, check for pressure gauge inaccuracies. |

| Material Compatibility | Ensure materials used for valves are compatible with the medium being handled. | Conduct periodic reviews of materials to avoid corrosion and damage. | Look for signs of wear or disintegration and replace incompatible materials. |

| Sealing Mechanisms | Seals prevent leaks and maintain pressure integrity in valves. | Inspect seals regularly and replace worn out or damaged seals promptly. | If leaks are detected, check for seal damage and re-evaluate the installation. |

| Regular Maintenance | Scheduled checks help ensure performance and longevity of relief valves. | Create a maintenance schedule that includes cleaning, testing, and inspection. | Monitor valve operation; inconsistent performance may indicate the need for servicing. |

| Calibration | Proper calibration is crucial for accurate pressure response. | Use standardized calibration equipment and follow manufacturer guidelines. | If pressure readings are erratic, recalibrate the system or replace faulty gauges. |

The future of remote control valve innovations is marked by a significant shift towards enhanced efficiency, driven by technological advancements and the growing importance of smart systems in industrial applications. The integration of intelligent technologies allows users to remotely monitor and adjust crucial parameters, such as temperature, humidity, and pressure, significantly improving operational flexibility. With the continued development of sensors and data analytics, industries are gaining real-time insights, leading to informed decision-making and optimized performance.

As the market for PTFE-lined plug valves is projected to grow from $64.14 million in 2024 to $84.01 million by 2032, with a steady annual growth rate of 3.4%, manufacturers are focusing on innovative designs and materials that enhance valve reliability and efficiency. The HVAC sector is also undergoing transformative changes, adopting smart technologies that redefine indoor environmental management.

These advancements not only promise improvements in performance but also contribute to sustainability efforts, as control systems become more energy-efficient and resource-conscious. As companies navigate this era of innovation, the emphasis on smart remote control valves will play a pivotal role in shaping the future of industrial operations.