Selecting the right Pressure Reducing Relief Valve for your system is a critical decision that can significantly impact safety and efficiency. With numerous options available on the market, it’s essential to understand the key factors that influence performance and reliability. This ultimate guide provides you with seven essential tips to navigate through the selection process, ensuring that you choose a valve that meets the specific requirements of your application. From understanding pressure ratings and materials to considering installation and maintenance needs, this blog will equip you with the knowledge necessary to make informed decisions.

Whether you’re managing a complex industrial system or a simpler setup, following these tips will help you optimize your system’s functionality and protect it from potential hazards related to overpressure scenarios.

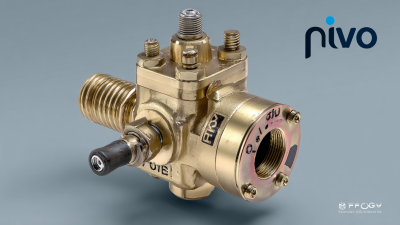

Pressure reducing relief valves play a critical role in maintaining optimal performance and safety in various systems. These valves help regulate pressure levels, preventing damage to equipment and ensuring efficient operation. When selecting the right valve, it’s essential to understand the specific requirements of your application, as well as the valve's characteristics and capabilities.

One crucial tip for choosing a pressure reducing relief valve is to consider your system's pressure range and flow requirements. Ensure that the selected valve can handle the operational conditions of your system, including maximum pressure and flow rates. Additionally, look into the valve's response time and dynamic characteristics, as these factor into the efficiency and reliability of your system.

Another important aspect is the compatibility of the valve materials with the fluids in your system. Different applications may use various types of fluids, and understanding the chemical compatibility will prevent premature failure or leaks. Advances in sensor technologies are also enhancing the ability to monitor valve performance, allowing for early detection of issues that could lead to system inefficiencies or failures. By focusing on these key considerations, you can ensure that your pressure reducing relief valve serves its intended purpose effectively.

This chart illustrates the importance level of various criteria for selecting a pressure reducing relief valve for your system. Understanding these factors can help ensure optimal performance and safety in your operations.

When selecting a pressure reducing relief valve (PRV) for your system, understanding the key specifications is crucial for optimizing performance and ensuring safety. First, it's essential to identify the pressure drop across the valve, which should include an analysis of the total friction energy loss within the system. Research indicates that pressure drop should be calculated after excluding static energy losses, allowing for a more accurate assessment of the dynamic operating conditions within your water distribution network (WDN). These systems are vital infrastructures, and careful selection of valve specifications can significantly influence operational efficiency.

Another crucial specification is the flow capacity of the PRV, which must align with the maximum anticipated flow rates in your application. In gas lift wells, it's essential to consider inflow relationships and how wellbore and facility parameters interact with the selected valve. Studies demonstrate that optimizing these parameters can enhance the overall effectiveness of fluid management strategies, particularly in water or gas systems. By leveraging advanced modeling techniques, such as adaptive neuro-fuzzy inference systems, engineers can better predict failure rates and enhance the reliability of their systems, thus ensuring long-term operational integrity.

When selecting a pressure reducing relief valve (PRV), material compatibility is crucial for maintaining durability and performance under varying operational conditions. According to the American Society of Mechanical Engineers (ASME), over 40% of valve failures result from material degradation due to corrosion or improper material selection. It is essential to analyze the fluid characteristics, including temperature, pressure, and chemical composition, to ensure the materials used can withstand these conditions without compromising functionality.

For instance, in applications involving corrosive fluids, stainless steel or high-density polyethylene (HDPE) may be better choices due to their superior resistance to corrosion compared to standard carbon steel. A report by the Valve Manufacturers Association indicates that the life expectancy of a PRV can significantly increase—by as much as 30%—when appropriate materials are employed. By investing in the right materials that align with the specific requirements of your system, you can enhance both the resilience and efficiency of your pressure management, ensuring long-term operational reliability.

When it comes to selecting a pressure reducing relief valve, assessing installation and maintenance considerations is crucial for ensuring optimal functionality. The right valve should not only fit your system's specifications but also be straightforward to install and maintain.

Tip 1: Always choose a valve that matches the piping configuration. This ensures a smooth installation process and reduces the risk of leaks or operational issues later on.

Regular maintenance is vital for the reliability of relief valves.

Tip 2: Schedule routine inspections to check for wear and tear or any corrosion that can compromise performance. Valves should be easily accessible for maintenance, which makes the layout of the installation site significant. Ensuring that there is enough space around the valve can facilitate prompt maintenance, thereby extending its lifespan.

Lastly, consider the operational conditions your valve will face.

Tip 3: Select a valve that can handle the expected pressure differentials and flow rates in your system. This not only enhances performance but also minimizes the risk of unexpected failures, ensuring that your setup operates smoothly under varying conditions.

When it comes to selecting a pressure reducing relief valve (PRRV) for your system, understanding the various brands and models available can significantly impact your choice. Popular manufacturers such as Anderson Greenwood, Burkert, and Goetze offer a wide range of PRRVs known for their reliability and efficiency.

Anderson Greenwood valves are designed for high pressure applications, providing durability in demanding environments. Meanwhile, Burkert's innovative designs include features like integrated electronics for precise control, making them suitable for modern automated systems.

Anderson Greenwood valves are designed for high pressure applications, providing durability in demanding environments. Meanwhile, Burkert's innovative designs include features like integrated electronics for precise control, making them suitable for modern automated systems.

In addition to brand reputation, it’s crucial to consider the specific models that best fit your system's requirements. For instance, the Goetze Safety Valve is praised for its compact design and ease of maintenance, making it an optimal choice for tight spaces. The ProFlow series from Anderson Greenwood is another excellent option, known for its versatility and high flow rates. By exploring these popular brands and understanding their unique offerings, you can ensure that you are selecting a PRRV that not only meets your technical specifications but also enhances the efficiency and safety of your operation.