Top 3-Way 2 Position Air Valve Manufacturers in China - Quality and Reliability

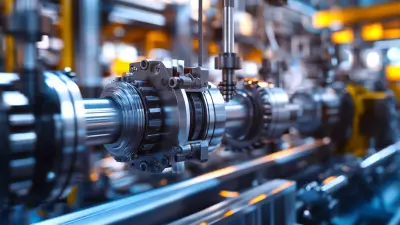

The 3 Way 2 Position Air Valve by Ningbo Longerfa Hydraulic Co., Ltd. is a crucial component for managing fluid and gas flow in various pneumatic systems. Built for durability and high performance, this valve stands up to demanding environments. With its ability to quickly switch between two positions, it offers flexible control suitable for multiple applications. The compact design allows for effortless installation, while its intuitive operation makes it accessible for technicians and engineers. Committed to the highest quality standards, Ningbo Longerfa ensures each valve meets strict performance criteria. Its excellent sealing capabilities and low maintenance needs make this valve ideal for industries such as manufacturing and automotive. Trust Ningbo Longerfa for advanced hydraulic solutions that elevate efficiency and dependability.How To Evaluate 3 Way 2 Position Air Valve Your End-to-End Solution Delivers Unmatched Quality

At Ningbo Longerfa Hydraulic Co., Ltd., we understand that selecting the right air valve can significantly impact the performance and efficiency of your Hydraulic Systems. Our expertise in designing and manufacturing hydraulic valve sets, including the three-way, two-position air valve, ensures that you get an end-to-end solution that stands out in quality. When evaluating these crucial components, it’s essential to consider factors such as material durability, pressure ratings, and response times. Our valves are rigorously tested to meet national high-tech standards, ensuring reliability in demanding applications. Quality evaluation begins with understanding the manufacturer’s capabilities. As a professional producer with extensive experience and technological advancements, Longerfa is dedicated to delivering precision-engineered products. Our three-way, two-position air valves are designed to provide exceptional control and flexibility in your hydraulic systems, whether you require them for industrial automation or mobile machinery. By prioritizing performance and compliance with global standards, we guarantee that your investment translates into enhanced operational efficiency and reduced downtime. In conclusion, choosing the right hydraulic components is paramount for optimizing your system's overall performance. At Longerfa, we not only provide high-quality hydraulic products but also offer expert insights to help you make informed decisions. Our commitment to innovation and excellence positions us as your trusted partner in hydraulic solutions, ensuring that you receive unmatched quality tailored to your specific needs. Explore our range of hydraulic products and discover how we can elevate your operational capabilities today.

How To Evaluate 3 Way 2 Position Air Valve Your End-to-End Solution Delivers Unmatched Quality

| Criteria | Description | Rating (1-5) |

|---|---|---|

| Material Quality | Assess the materials used in construction for durability and performance. | 4 |

| Flow Rate | Evaluate the maximum flow rate and efficiency at which the valve operates. | 5 |

| Ease of Maintenance | Review the design for accessibility and ease of servicing. | 4 |

| Response Time | Check the time taken for the valve to open and close. | 5 |

| Pressure Rating | Identify the maximum pressure the valve can handle safely. | 4 |

| Cost Effectiveness | Analyze the cost in relation to performance and lifespan of the valve. | 3 |

| Warranty and Support | Consider the warranty period and quality of customer support offered. | 5 |

Ultimate Guide To 3 Way 2 Position Air Valve Ahead of the Curve Industry Giant

N

Nancy Hall

The product is of outstanding quality. Their customer service made a difference, handling my queries with expertise and care.

09 June 2025

M

Megan Davis

This product is fantastic! The support staff were knowledgeable and guided me perfectly.

13 June 2025

C

Caleb Adams

High-quality product! Their customer service offered invaluable assistance during my purchase.

25 June 2025

C

Chase Wilson

Exceptional buying experience! The product quality and customer service far exceeded my expectations.

17 May 2025

I

Isaac Hall

Excellent quality, and the support team was very responsive and knowledgeable.

27 June 2025

Z

Zoe Perez

I am very pleased with the product! Their after-sales support was professional and helpful.

12 May 2025