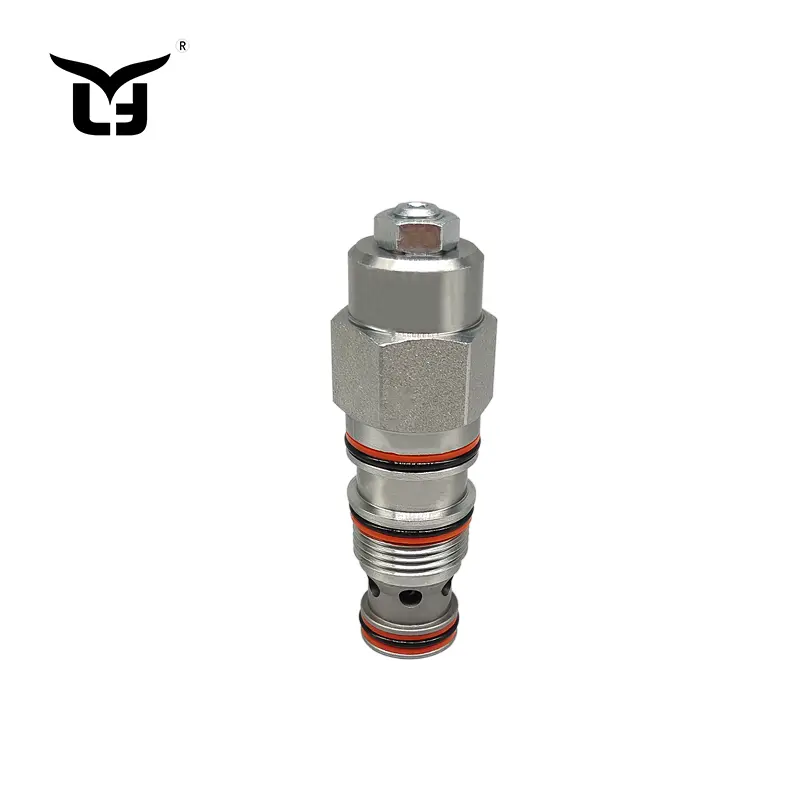

Leading Unidirectional Throttle Valve Manufacturers in China for Quality Solutions

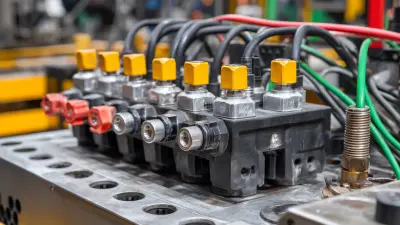

The Unidirectional Throttle Valves from Ningbo Longerfa Hydraulic Co., Ltd. are engineered for optimal efficiency and precision in fluid control applications. These valves allow for precise regulation of flow in one direction, effectively minimizing the risk of backflow and ensuring peak performance in hydraulic systems. Crafted from high-quality materials, they promise durability and reliable operation across diverse environmental conditions. Our valves feature a compact design that simplifies installation and maintenance, making them suitable for both new systems and retrofits. With a strong emphasis on innovation and customer satisfaction, Ningbo Longerfa Hydraulic Co., Ltd. delivers exceptional products along with expert support tailored to your specific needs, enhancing the functionality and reliability of your hydraulic systems with precision-engineered solutions.7 Key Tips To Unidirectional Throttle Valves Manufacturers Ahead of the Curve Is The Best

In today’s competitive marketplace, staying ahead of the curve is essential for manufacturers, especially for those involved in precision engineering like unidirectional throttle valves. At Ningbo Longerfa Hydraulic Co., Ltd., a recognized high-tech enterprise, we understand the unique challenges and opportunities that global buyers face when sourcing hydraulic components. Our expertise not only lies in the research and development of Hydraulic Valve sets but also in producing superior products that meet international standards. To ensure your business thrives, here are seven key tips for efficiently collaborating with manufacturers like us. First, prioritize understanding the technical specifications and capabilities of the components you need. Engaging directly with manufacturers can provide clarity about quality and performance. Second, assess the supplier's production capacity and technological advancements, as these factors will influence lead times and product availability. Third, leverage our R&D expertise to customize products that align with your specific requirements. Moreover, establishing clear communication channels is vital for addressing any concerns promptly. Fourth, consider long-term partnerships that can offer stability in supply and pricing. Fifth, explore the manufacturer's certifications and industry experience to gauge reliability. Lastly, stay informed about global market trends that can impact hydraulic systems and be proactive in adapting your procurement strategies accordingly. By following these tips, you can make informed decisions and ensure that your sourcing of unidirectional throttle valves not only meets current needs but also positions your business for future success.

7 Key Tips To Unidirectional Throttle Valves Manufacturers Ahead of the Curve Is The Best

| Tip Number | Tip Description | Importance Level | Implementation Status |

|---|---|---|---|

| 1 | Focus on Advanced Materials | High | In Progress |

| 2 | Invest in Automation Technology | Medium | Not Started |

| 3 | Enhance Customer Service | High | Completed |

| 4 | Optimize Production Processes | High | In Progress |

| 5 | Develop Sustainable Practices | Medium | Planned |

| 6 | Strengthen Supply Chain Relationships | High | Ongoing |

| 7 | Expand Research and Development | High | Not Started |

Best Practices For Unidirectional Throttle Valves Manufacturers Guarantees Peak Performance Your End-to-End Solution

E

Emily Johnson

Fantastic product! The support team provided expert guidance throughout the whole process.

14 May 2025

D

David Wilson

Excellent quality! The post-purchase support was exceptional, with knowledgeable staff willing to assist.

30 June 2025

D

Daniel Martin

Top-quality product. The after-sales service is commendable; their staff went above and beyond to assist me.

09 May 2025

A

Alexander Martinez

Quality is impeccable! Their after-sales team is knowledgeable and courteous.

02 July 2025

D

David Jones

I’m extremely pleased! The quality is excellent, and the customer service has been fantastic.

04 July 2025

C

Cameron Robinson

Exceptional value for the quality! Their support team was very helpful in assisting me.

03 July 2025