Top High-Quality Valves for Hydraulic Systems in Factory Applications

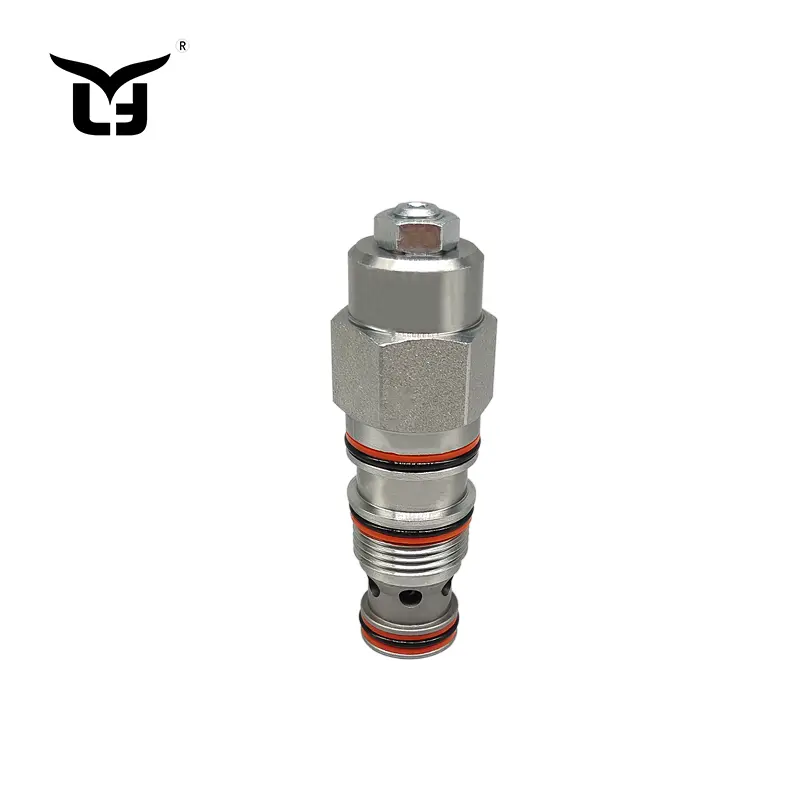

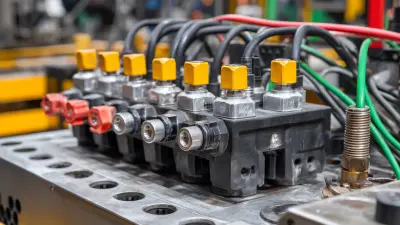

Ningbo Longerfa Hydraulic Co., Ltd. offers a comprehensive range of hydraulic valves tailored for optimal performance in various industrial applications. Our selection includes directional control valves, pressure relief valves, flow control valves, and check valves, all meticulously engineered for precision and reliability. The directional control valves efficiently manage fluid flow, ensuring smooth machinery operations. Pressure relief valves enhance system safety by preventing pressure levels from exceeding safe limits, promoting longevity. Flow control valves provide the adaptability to adjust flow rates, ideal for applications requiring precise control. Our check valves effectively prevent backflow, contributing to a consistent and efficient hydraulic system. Manufactured with high-quality materials and cutting-edge technology, our valves are designed to endure demanding conditions and deliver outstanding performance. Trust Ningbo Longerfa Hydraulic Co., Ltd. for hydraulic solutions tailored to your specific requirements, and experience the impact of our quality valves on your operations.Best Way To Choose Types Of Valves In Hydraulic System Factories Market Leader Guarantees Peak Performance

When it comes to selecting the best types of valves for hydraulic systems, understanding the unique needs of your projects is crucial. As global industries turn to experts like Ningbo Longerfa Hydraulic Co., Ltd., it’s essential to know what determines peak performance in hydraulic components. With a focus on research and development, Longerfa prides itself on being a national high-tech enterprise specializing in hydraulic valve sets, hydraulic thread plug valves, and more. This expertise ensures that the valves produced not only meet but exceed international standards. One of the main considerations in choosing the right valves is the specific application requirements. Different hydraulic systems demand valves that can handle varying pressures, flow rates, and environmental conditions. At Longerfa, our dedicated R&D team collaborates closely with clients to customize solutions tailored to their operational environments, ensuring optimal functionality and longevity. By leveraging advanced technologies and manufacturing processes, we can guarantee that our products deliver peak performance, supporting your projects with reliability and efficiency. Furthermore, assessing the quality and durability of hydraulic valves is essential for long-term sustainability and cost-effectiveness. Longerfa’s commitment to high-quality production standards results in valves that withstand wear and tear, minimizing downtime and maintenance costs. As you navigate the competitive landscape of hydraulic components in the global market, partnering with a manufacturer like Longerfa ensures that you are equipped with top-tier products designed to keep your operations running smoothly and successfully.

Best Way To Choose Types Of Valves In Hydraulic System Factories Market Leader Guarantees Peak Performance

| Valve Type | Application | Pressure Rating (psi) | Flow Rate (GPM) | Material |

|---|---|---|---|---|

| Ball Valve | General Flow Control | 3000 | 10 | Steel |

| Gate Valve | On/Off Control | 2500 | 15 | Cast Iron |

| Check Valve | Prevent Backflow | 2000 | 8 | Brass |

| Relief Valve | Pressure Regulation | 1500 | 6 | Aluminum |

| Directional Control Valve | Flow Direction Control | 2000 | 12 | Plastic |

How To Pick The Right Types Of Valves In Hydraulic System Factories Manufacturer Outperforms the Competition

S

Sarah Davis

This product has truly transformed my experience. The follow-up from their support team was both timely and informative.

29 June 2025

J

Jessica Turner

I love this product! The support staff were incredibly knowledgeable and responsive, adding great value to my purchase.

25 June 2025

S

Stephen Lewis

The quality of this product is unparalleled! Their service team helped me with my inquiries promptly.

02 July 2025

D

David Jones

I’m extremely pleased! The quality is excellent, and the customer service has been fantastic.

04 July 2025

J

Joshua Hall

Outstanding quality! The customer service representatives were also very thorough and attentive.

19 June 2025

E

Ella White

Excellent item! The after-sales team was professional, ensuring all my questions were answered.

22 May 2025