Quality Two Way Pneumatic Valves from Leading Manufacturer in China

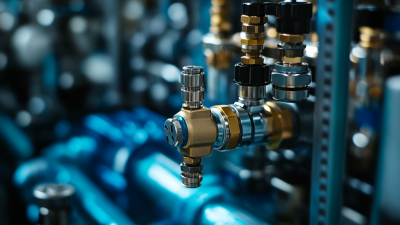

The Two Way Pneumatic Valve from Ningbo Longerfa Hydraulic Co., Ltd. is an essential device designed to optimize fluid control within pneumatic systems. With its efficient and reliable design, it facilitates precise regulation of airflow in both directions, making it suitable for a wide range of industrial applications. Constructed from high-quality materials, this valve ensures durability and longevity even in challenging environments. Engineered for quick response times, it enhances overall system performance while effectively minimizing energy consumption. The compact design allows for straightforward installation and integration into existing systems, while advanced sealing technology significantly reduces the risk of leaks. Prioritizing innovation and quality, Ningbo Longerfa Hydraulic Co., Ltd. guarantees that each valve meets strict industry standards. Ideal for automation and manufacturing applications, this Two Way Pneumatic Valve is a trusted choice for engineers and technicians aiming to improve operational efficiency and reliability in their pneumatic systems.10 tips Two Way Pneumatic Valve Service Dominates

As the need for reliable and efficient valve systems continues to grow, the importance of proper maintenance and servicing of two-way pneumatic valves cannot be overstated. At Ningbo Longerfa Hydraulic Co., Ltd., we understand that well-maintained valves are crucial for enhancing performance and prolonging service life. Here are ten essential tips that can help ensure your two-way pneumatic valves operate optimally. First, regular inspections are vital. Check for signs of wear, corrosion, or leaks, which can significantly affect functionality. Ensure that all components, including seals and actuators, are in good condition to prevent potential failures. Second, cleanliness is key. Keep the valve and its surroundings tidy to avoid contaminants that could compromise operation. Third, ensure the correct installation by following manufacturer guidelines; improper mounting can lead to premature wear and malfunction. Additionally, regular lubrication helps prevent friction and wear, contributing to smoother operation. Pairing this with timely calibration ensures that your valves respond accurately to control signals. Lastly, maintaining a service record can assist in predicting maintenance needs based on usage patterns, ultimately reducing downtime. By implementing these tips, you can ensure optimal performance from your pneumatic valves, thereby enhancing the efficiency of your Hydraulic Systems. Partner with Ningbo Longerfa Hydraulic Co., Ltd., a national high-tech enterprise, to access high-quality hydraulic products designed for excellence.

10 Tips Two Way Pneumatic Valve Service Dominates

| Tip Number | Tip Description | Frequency of Service | Expected Outcome |

|---|---|---|---|

| 1 | Regularly inspect the valve for leaks | Monthly | Preventive maintenance, reduced downtime |

| 2 | Clean the actuator and valve body | Quarterly | Improved performance and efficiency |

| 3 | Replace worn seals and gaskets | Annually | Reduced leaks, enhanced sealing |

| 4 | Check and calibrate pressure settings | Bi-Annual | Optimal operation, controlled performance |

| 5 | Inspect the pneumatic lines for damage | Monthly | Preventive measure, safe operation |

| 6 | Lubricate moving parts as required | Every two months | Reduced friction, extended service life |

| 7 | Test the valve operation under load | Semi-Annually | Validates performance in real conditions |

| 8 | Update service records for each valve | Ongoing | Accurate maintenance history |

| 9 | Structured training for operators | Annual | Enhanced safety and operation knowledge |

| 10 | Implement predictive maintenance strategies | Continuous | Minimizes unplanned downtime |

Pinpointing Two Way Pneumatic Valve in 2025 Service

J

Jessica Brown

The product has proven to be durable and reliable. The customer service staff were supportive and approachable.

14 June 2025

F

Frank Scott

This product has met all my expectations. The post-sale support was timely and very knowledgeable.

14 May 2025

A

Andrew Nelson

Superb quality! The follow-up service was remarkably good, demonstrating a commitment to customer care.

04 June 2025

E

Edward Hall

Great purchase! The product is exceptional, and their customer service was equally impressive.

10 June 2025

C

Cameron Robinson

Exceptional value for the quality! Their support team was very helpful in assisting me.

03 July 2025

C

Caleb Adams

High-quality product! Their customer service offered invaluable assistance during my purchase.

25 June 2025