High-Quality OEM Throttle Valve for Hydraulic Systems | Trusted Factory Products

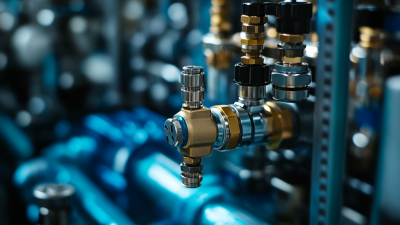

Ningbo Longerfa Hydraulic Co., Ltd. offers advanced throttle valves engineered for hydraulic systems. These essential components regulate fluid flow, enhancing system performance and efficiency. Crafted with precision, our throttle valves ensure accurate pressure and flow rate control, thereby optimizing system responsiveness and minimizing energy usage. Built from high-quality materials, they are designed to endure challenging industrial conditions, providing durability and extended service life. The innovative design facilitates straightforward installation and maintenance, making these valves suitable for a variety of industries, including automotive, construction, and machinery. Whether enhancing control in hydraulic circuits or upgrading existing systems, our throttle valves provide dependable solutions tailored to your specific needs. Trust Ningbo Longerfa Hydraulic Co., Ltd. for superior quality and innovation in hydraulic components, ensuring enhanced performance and reliability.Expert Tips For Throttle Valve In Hydraulic System Factory Products Where Service Meets Innovation

At Ningbo Longerfa Hydraulic Co., Ltd., we understand the critical role that throttle valves play in hydraulic systems. As a national high-tech enterprise specializing in the research and development of hydronic solutions, we are committed to providing our global clients with innovative products that meet evolving industry standards. Our throttle valves are engineered to enhance the performance and efficiency of hydraulic systems, ensuring that your machinery operates smoothly under various conditions. To maximize the effectiveness of these essential components, it's vital to focus on key parameters such as valve design, response time, and material selection. Our state-of-the-art manufacturing techniques allow us to produce throttle valves that not only maintain precise flow control but also exhibit durability and reliability in demanding environments. We invite procurement specialists worldwide to explore our range of Hydraulic Valve sets and components that blend quality craftsmanship with cutting-edge technology, reinforcing our reputation as a trusted partner in the hydraulic sector. By partnering with Ningbo Longerfa Hydraulic Co., Ltd., you gain access to expert insights and a commitment to innovation that can significantly impact your hydraulic operations. Our customer-centric approach emphasizes collaboration, enabling you to find solutions tailored to your specific needs. Whether you seek to enhance productivity or improve system stability, our throttle valves and hydraulic products are designed for optimal performance and longevity. Join us in revolutionizing hydraulic systems worldwide.

Expert Tips For Throttle Valve In Hydraulic System Factory Products Where Service Meets Innovation

| Tip Category | Expert Tip | Benefits | Innovation Aspect |

|---|---|---|---|

| Maintenance | Regularly check and clean the throttle valve | Prevents clogging and ensures smooth operation | Utilizing smart sensors for regular diagnostics |

| Installation | Install with proper alignment to avoid leaks | Reduces the risk of oil leaks | Use of self-aligning technology for easier setup |

| Testing | Perform pressure tests to ensure functioning | Confirms the integrity of the throttle valve | Incorporating automated pressure testing systems |

| Choosing Materials | Select corrosion-resistant materials | Increases lifespan of the valve | Research into advanced composites and coatings |

| Calibration | Regular calibration based on system requirements | Ensures optimal performance and efficiency | Advanced calibration tools for precision |

How To Source Throttle Valve In Hydraulic System Factory Stands Out Global Reach

J

James Thompson

The product quality exceeded my expectations. The support team was incredibly professional and responsive.

09 May 2025

J

Jessica Brown

The product has proven to be durable and reliable. The customer service staff were supportive and approachable.

14 June 2025

D

Daniel Martin

Top-quality product. The after-sales service is commendable; their staff went above and beyond to assist me.

09 May 2025

K

Kevin Perez

Excellent craftsmanship! The follow-up service was superb, showcasing a true commitment to customer satisfaction.

26 June 2025

B

Brittany Wood

Loving my new product! The support staff provided excellent assistance and were very professional throughout.

01 July 2025

A

Alice Green

A fantastic item! The after-sales service team were well-trained and very helpful with everything I needed.

08 June 2025