High-Quality OEM Reverse Flow Check Valves from Trusted Manufacturers

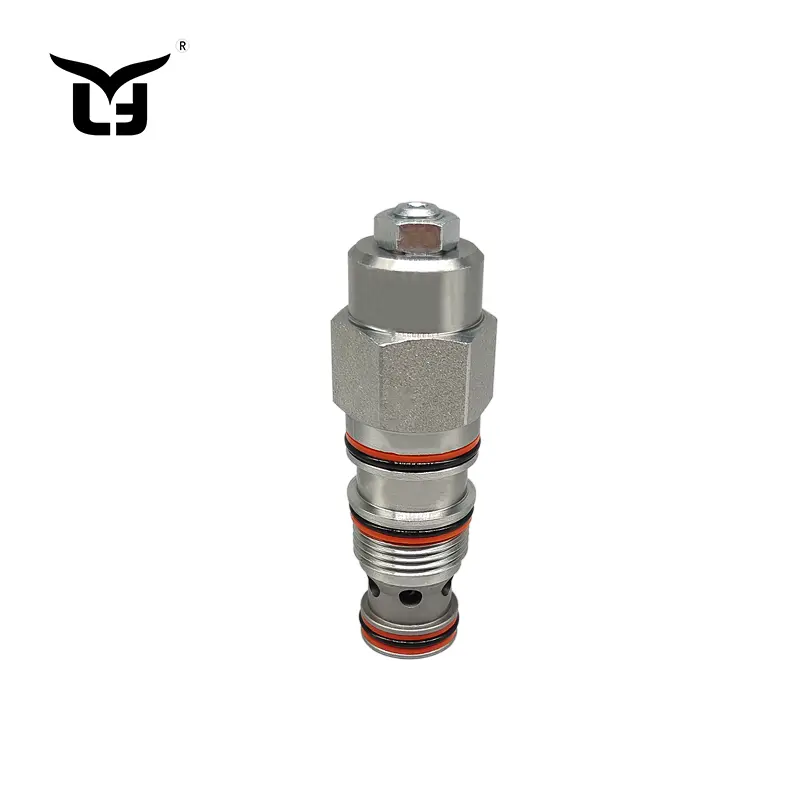

The Reverse Flow Check Valve from Ningbo Longerfa Hydraulic Co., Ltd. effectively prevents backflow in fluid systems, ensuring operational efficiency and system integrity. Designed for precision, this valve permits flow in one direction while completely blocking any reverse flow. It is well-suited for various applications in hydraulic systems, water treatment, and industrial processes. Constructed from top-quality materials, the valve offers outstanding durability and wear resistance, promising long-lasting performance in even the most demanding environments. Its compact design facilitates easy installation and seamless integration into existing systems. Operating quietly, this valve minimizes noise levels in your setup. With rigorous testing and compliance with international standards, the Reverse Flow Check Valve stands as a reliable solution for safeguarding your systems against potential disruptions. Trust Ningbo Longerfa Hydraulic Co., Ltd. for advanced hydraulic solutions that elevate productivity and ensure system stability.How To Compare Reverse Flow Check Valve Stands Out Service Backed by Expertise

At Ningbo Longerfa Hydraulic Co., Ltd., we pride ourselves on offering expertise and innovation in the realm of hydraulic products, particularly with our high-quality reverse flow check valves. These crucial components are designed to prevent backflow in hydraulic systems, ensuring reliability and efficiency. As a national high-tech enterprise, we leverage advanced research and development capabilities to create check valves that not only meet but exceed global standards. When comparing reverse flow check valves, it’s essential to consider factors such as durability, material quality, and operational performance. Our products are engineered with precision, employing state-of-the-art technology and rigorous testing protocols to guarantee that they withstand the demands of various industrial applications. By choosing Longerfa, you benefit from our extensive knowledge and commitment to excellence, which translates into superior service and support tailored specifically to your needs. Furthermore, our global customer base can rely on our responsive service and in-depth expertise available at every touchpoint. Whether you are looking for customized solutions or need advice on your specific hydraulic requirements, our dedicated team is ready to assist you. Let Ningbo Longerfa Hydraulic Co., Ltd. be your trusted partner in hydraulic solutions—experience the difference that our outstanding service and industry-leading expertise can make for your operations.

How To Compare Reverse Flow Check Valve Stands Out Service Backed by Expertise

| Criteria | Option A | Option B | Option C |

|---|---|---|---|

| Material Quality | Brass | Stainless Steel | Plastic |

| Pressure Rating | 150 PSI | 200 PSI | 100 PSI |

| Temperature Range | -20 to 150 °C | -30 to 200 °C | 0 to 100 °C |

| Flow Rate | 50 GPM | 75 GPM | 30 GPM |

| End Connections | Threaded | Flanged | Socket Weld |

| Warranty Period | 1 Year | 2 Years | 6 Months |

Don't Miss These Reverse Flow Check Valve Your Trusted OEM Partner Supplies the World’s Top Brands

L

Linda Reynolds

I am extremely satisfied with the product. The customer service representatives were knowledgeable and very helpful.

11 May 2025

D

David Wilson

Excellent quality! The post-purchase support was exceptional, with knowledgeable staff willing to assist.

30 June 2025

K

Kimberly Robinson

Fantastic experience all around! The quality of the item and the professionalism of the support staff stood out.

06 May 2025

B

Brian Walker

Delighted with my purchase! The product quality is remarkable, and their support staff were professional and kind.

02 June 2025

M

Michelle Clark

Fantastic item! The after-sales service was helpful, and the representatives were very knowledgeable.

09 June 2025

W

Wyatt Edwards

The product quality is superb! Their after-sales service was prompt and professional.

18 June 2025