High-Quality Remote Hydraulic Valves from Leading Manufacturers - Top Choices Available

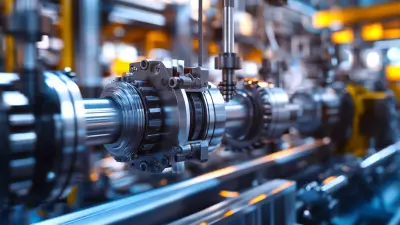

Ningbo Longerfa Hydraulic Co., Ltd. specializes in premium remote hydraulic valves that enhance efficiency and precision in various hydraulic systems. Our advanced valves are designed for seamless integration across applications, including industrial machinery and agricultural equipment, ensuring reliable and responsive control. Built for durability, these remote hydraulic valves provide outstanding performance even in challenging environments. Key features include easy installation, adjustable flow rates, and robust construction, allowing users to optimize their hydraulic operations while prioritizing safety and reliability. With years of expertise, our team focuses on innovation and customer satisfaction, delivering tailored solutions for specific operational needs. Choose Ningbo Longerfa Hydraulic Co., Ltd. for advanced hydraulic technology that elevates your business operations and enhances control and efficiency.Must-Know Tips For Remote Hydraulic Valve Manufacturers Factory Industry Leaders

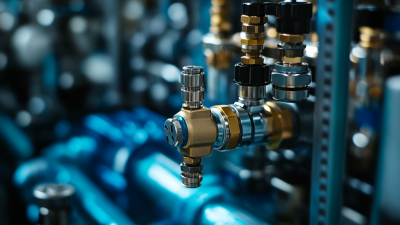

In the evolving world of hydraulic manufacturing, remote hydraulic valve manufacturers face unique challenges and opportunities. For industry leaders, understanding key strategies can streamline processes and enhance productivity. At Ningbo Longerfa Hydraulic Co., Ltd., we specialize in researching and developing hydraulic valve sets, thread plug valves, valve blocks, and various hydraulic components. Our status as a national high-tech enterprise underscores our commitment to innovation and quality. To thrive in this competitive landscape, manufacturers must prioritize research and development. Continuous improvement not only enhances product performance but also ensures compliance with international standards, appealing to global buyers. Furthermore, effective communication through digital platforms helps in building trust with international partners, ensuring transparency in transactions and fostering long-term relationships. Investing in cutting-edge technology and adopting lean manufacturing practices can dramatically increase efficiency. Automation and precision engineering reduce error margins and production costs, allowing manufacturers to offer competitive pricing. By following these must-know tips, global procurement specialists can identify reliable suppliers like Ningbo Longerfa, ensuring they source high-quality hydraulic products tailored to their needs.

Must-Know Tips For Remote Hydraulic Valve Manufacturers Factory Industry Leaders

| Tip | Description | Impact on Production | Implementation Cost |

|---|---|---|---|

| Automate Processes | Utilize automation technologies to enhance efficiency. | Increases throughput and quality consistency. | High initial cost, but significant long-term savings. |

| Invest in R&D | Focus on research and development for innovative solutions. | Keeps products competitive and meets new market demands. | Moderate cost, dependent on scale of investment. |

| Quality Control Systems | Implement strict quality control to minimize defects. | Reduces returns and increases customer satisfaction. | Low to moderate cost, mainly personnel training. |

| Eco-Friendly Practices | Adopt environmentally friendly manufacturing practices. | Enhances brand reputation and compliance with regulations. | Moderate cost; potential cost savings on materials. |

| Remote Monitoring | Utilize IoT for real-time monitoring of processes. | Detects issues early, reducing downtime. | Potentially high cost for setup; long-term savings. |

How To Decide Between Remote Hydraulic Valve Manufacturers Service For the Current Year

J

Jessica Turner

I love this product! The support staff were incredibly knowledgeable and responsive, adding great value to my purchase.

25 June 2025

K

Kevin Perez

Excellent craftsmanship! The follow-up service was superb, showcasing a true commitment to customer satisfaction.

26 June 2025

A

Alice Green

A fantastic item! The after-sales service team were well-trained and very helpful with everything I needed.

08 June 2025

G

George Lee

Excellent quality overall! The support staff demonstrated true skill and professionalism in resolving my queries.

20 June 2025

C

Chloe Brown

Top quality! The after-sales team was efficient and very professional in their approach.

12 May 2025

I

Isaac Hall

Excellent quality, and the support team was very responsive and knowledgeable.

27 June 2025