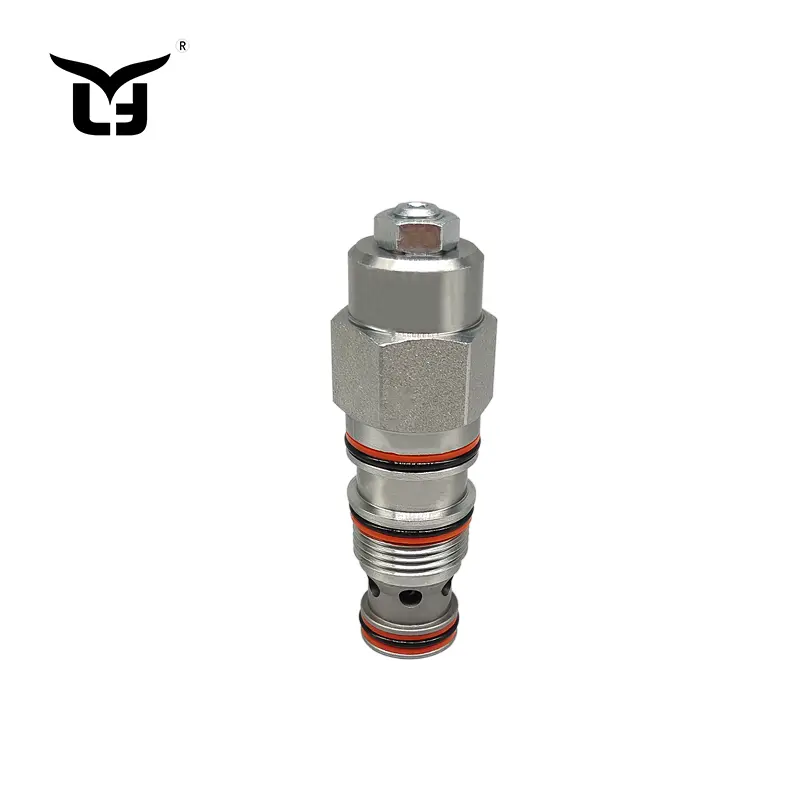

OEM Cartridge Counterbalance Valves from Leading China Factory - High Quality Options

OEM cartridge counterbalance valves from Ningbo Longerfa Hydraulic Co., Ltd. are meticulously designed to optimize hydraulic system performance, offering precise control and enhanced safety. These crucial components are instrumental in maintaining load stability and preventing uncontrolled movements in hydraulic cylinders, making them well-suited for various applications in construction, agriculture, and industrial machinery. Crafted from high-quality materials using advanced technology, our counterbalance valves deliver reliability and durability even in the most demanding conditions. Their compact design facilitates easy integration into existing systems, providing efficient space-saving solutions without compromising functionality. With a strong focus on customization, we offer tailored OEM solutions to meet diverse hydraulic configuration needs. Our dedication to quality and customer satisfaction has established us as a trusted name in the hydraulic component industry. Choose Ningbo Longerfa Hydraulic Co., Ltd. for outstanding OEM cartridge counterbalance valves that enhance your hydraulic applications' performance and safety.10 Essential Tips For OEM Cartridge Counterbalance Valves Now Trending Factory

In today's competitive market, OEM cartridge counterbalance valves are crucial for ensuring precision and efficiency in hydraulic systems. As these components gain popularity, it's essential for global purchasers to stay informed about the latest trends and best practices. At Ningbo Longerfa Hydraulic Co., Ltd., a recognized expert in manufacturing Hydraulic Valves and components, we understand the needs of our customers seeking high-quality solutions. First and foremost, it’s important to focus on the versatility and reliability of counterbalance valves. Selecting products that maintain consistent performance under varying loads can significantly enhance the efficiency of hydraulic systems. Additionally, consider the material and design of the valves—high-quality materials can improve durability and reduce maintenance costs. Moreover, keeping abreast of innovations in valve technology is crucial. Our commitment to research and development at Ningbo Longerfa ensures that we provide cutting-edge products tailored to evolving market demands. Lastly, establishing a solid partnership with a reputable manufacturer can lead to significant advantages. A reliable supplier not only offers superior products but also provides valuable technical support and customization options. With Ningbo Longerfa’s dedication as a national high-tech enterprise, we are poised to meet your exact specifications for OEM cartridge counterbalance valves. By implementing these essential tips, global buyers can enhance their procurement strategies and ensure optimal performance in their hydraulic applications.

10 Essential Tips For OEM Cartridge Counterbalance Valves Now Trending Factory

| Tip Number | Tip Description | Benefit | Implementation Time |

|---|---|---|---|

| 1 | Regular Maintenance Checks | Improves reliability | Weekly |

| 2 | Proper Installation | Minimizes leak risks | 1 Day |

| 3 | Use Quality Seals | Enhances durability | Immediate |

| 4 | Calibrate Regularly | Ensures accurate performance | Monthly |

| 5 | Monitor Operating Conditions | Prevents overheating | Ongoing |

| 6 | Choose Suitable Materials | Increases lifespan | At design phase |

| 7 | Documentation of Performance Metrics | Aids in troubleshooting | Ongoing |

| 8 | Standardize Procedures | Ensures consistency | Immediate |

| 9 | Regular Training for Staff | Improves operational safety | Quarterly |

| 10 | Utilize Modern Technology | Enhances efficiency | Ongoing |

why choose OEM Cartridge Counterbalance Valves Service Backed by Expertise Is The Best

J

James Thompson

The product quality exceeded my expectations. The support team was incredibly professional and responsive.

09 May 2025

M

Megan Evans

The product has worked perfectly for me. The support provided post-purchase was knowledgeable and reliable.

12 June 2025

N

Natalie Green

Exceptional product quality! The support team offered knowledgeable and friendly assistance.

07 May 2025

B

Benjamin White

The product quality is simply exceptional! The follow-up support was remarkably professional.

31 May 2025

E

Ella Harris

Wonderful product! The support staff demonstrated true professionalism and were very helpful.

09 June 2025

H

Hailey Allen

I’m thoroughly impressed! The quality is remarkable, and the service team was friendly.

03 July 2025