The Difference Between M4/M5 Pilot Relief Valves: Can They Be Used Interchangeably?

What are Pilot Relief Valves?

Before diving into the specific differences between the M4 and M5models, let’s first define what pilot relief valves are and how they work. A pilot relief valve is a type of pressure control valve used in Hydraulic Systems to maintain or limit the pressure within the system. The "pilot" refers to a secondary valve used to control the main valve’s operation.

When the system pressure exceeds a pre-set value, the pilot valve activates and allows the excess pressure to flow to the reservoir, preventing further pressure buildup. By doing so, the valve ensures that the system operates within a safe and effective pressure range, which is crucial for both system longevity and operator safety.

M4 Pilot Relief Valve

The M4 pilot relief valve is one of the most popular models used in various industries, from automotive to industrial manufacturing. Typically, it’s known for its precise pressure control and reliability. Key features of the M4 include:

-

Pressure Range: The M4 valve is typically designed to operate in a medium-range pressure spectrum, ideal for most standard hydraulic applications. It can handle pressures up to 350 bar, making it suitable for a wide array of systems where pressure control is essential.

-

Flow Control: The M4 valve is equipped with a fine-tuned flow control mechanism that ensures minimal fluctuation during pressure adjustments. This makes it highly reliable in systems that demand consistent performance.

-

Compact Design: The compact size of the M4 makes it an excellent choice for systems with limited space. Its efficiency in small packages allows for easy integration into a variety of machinery and systems.

-

Materials: The M4 valve is often constructed using durable materials that resist corrosion, such as stainless steel or brass. This makes the M4 highly suitable for applications in harsh environments where wear and tear are a concern.

-

Adjustability: The valve is often adjustable, allowing for fine-tuning of the pressure relief settings. This is crucial for operators who require specific pressure ranges for different operational conditions.

M5 Pilot Relief Valve

The M5 pilot relief valve is an upgraded and more robust version of the M4. While both models serve the same primary purpose, there are key differences that set them apart in terms of application and performance.

-

Pressure Range: The M5 valve generally operates in higher pressure ranges compared to the M4. It is suitable for high-pressure hydraulic systems and can handle pressures exceeding 500 bar. This makes it ideal for heavy-duty systems where more rigorous pressure control is necessary.

-

Enhanced Flow Capacity: One of the standout features of the M5 valve is its ability to manage higher flow rates, which is essential for large-scale industrial systems. It is designed for systems that require more extensive fluid throughput and pressure relief, such as in construction or mining machinery.

-

Durability and Longevity: The M5 is built to endure more demanding operational conditions, with a focus on reducing wear and improving service life. It often incorporates enhanced materials, such as hardened steel, and features that ensure longevity even in high-pressure environments.

-

Size and Weight: Due to its increased capacity, the M5 valve is generally larger and heavier than the M4. This makes it less suitable for compact systems where space is limited but ideal for large machines and industrial applications.

-

Specialized Adjustability: The M5 valve typically has a more intricate adjustment mechanism, allowing for finer control over pressure relief and operational settings. It is designed for systems where precision is critical, especially in applications that require fine-tuned adjustments under extreme pressure conditions.

Can M4 and M5 Pilot Relief Valves Be Used Interchangeably?

While the M4 and M5 pilot relief valves serve similar functions, their differences mean they are not always interchangeable. Here are several key factors to consider before using them interchangeably in your system:

1. Pressure Requirements

The M4 and M5 valves differ significantly in their pressure ratings. The M4 is designed for medium-range pressures, while the M5 is suited for high-pressure systems. If you were to use an M4 valve in a high-pressure system, it could fail to operate correctly, potentially causing system damage or failure. Similarly, using an M5 in a low-pressure system could result in over-engineering, which could add unnecessary costs without providing any performance benefits.

2. Flow Rate

The M5 valve is built to handle higher flow rates than the M4. If your system demands a higher flow rate, using an M4 valve in place of an M5 could result in inadequate flow control, leading to pressure spikes and reduced system efficiency. On the other hand, an M5 in a low-flow system may be unnecessarily large and inefficient, creating pressure fluctuations that hinder performance.

3. System Size and Compatibility

Due to the size difference, the M4 and M5 may not be compatible with the same system architecture. M4 valves are compact and designed for smaller systems, while M5 valves are larger and typically suited for industrial applications with more space. Before replacing one with the other, consider the physical compatibility of the valve with your system’s components.

4. Precision of Pressure Control

The M5 is designed for higher precision, especially in high-pressure applications. Using the M4 valve in place of the M5 in such systems could result in a loss of control over the pressure, as the M4 valve is not built for such exacting demands. If your system requires fine adjustments at high pressures, the M5 would be the better choice.

5. Material Durability

Given the differences in materials used for the M4 and M5, durability is another important factor to consider. If you are working in an environment with extreme conditions (e.g., high temperatures, abrasive fluids), the M5 valve, with its enhanced material quality, may be the more reliable option.

Conclusion

While both the M4 and M5 pilot relief valves serve the same fundamental purpose—pressure control within hydraulic systems—their differences make them suited for different applications. The M4 is ideal for medium-pressure, compact systems where space is at a premium and flow control is necessary. On the other hand, the M5 is built for high-pressure, high-flow systems where durability and precision are critical.

Can they be used interchangeably? In most cases, no. The differences in pressure range, flow capacity, size, and durability mean that one valve cannot simply replace the other without potentially compromising system performance and safety. Understanding these differences is crucial for selecting the correct valve for your specific application, ensuring the efficient, safe, and long-lasting operation of your hydraulic systems.

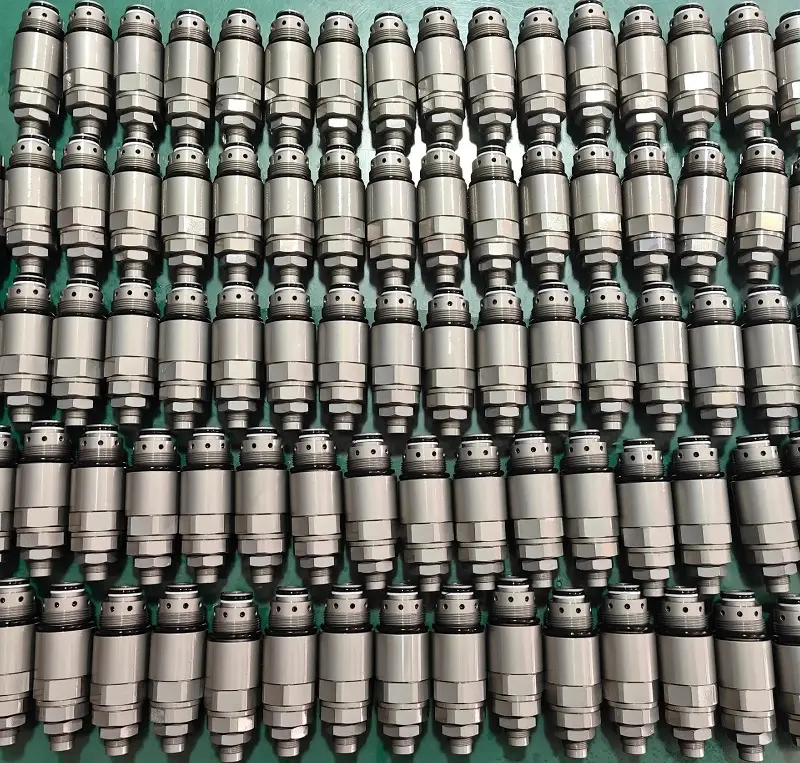

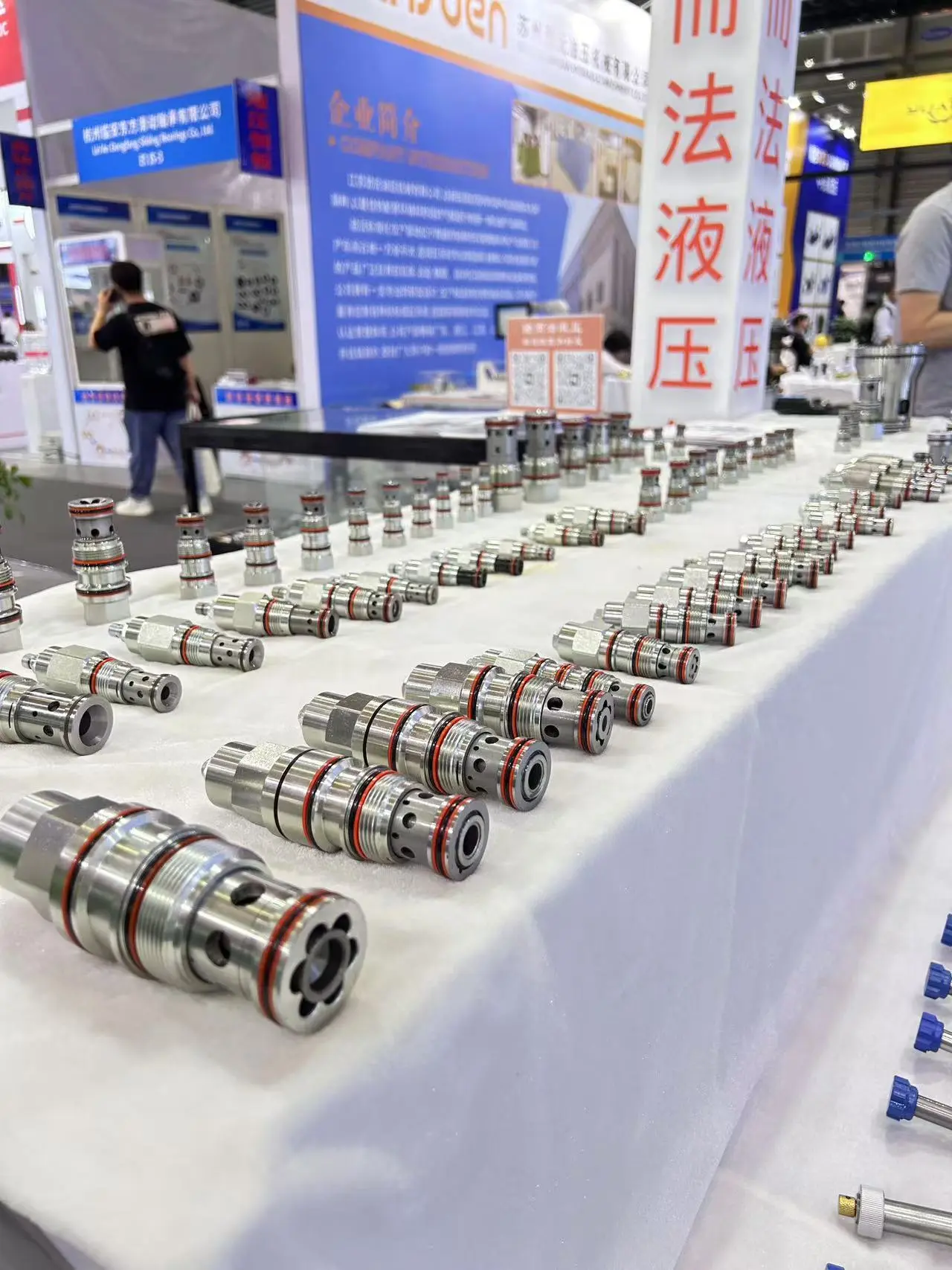

At Ningbo Longerfa, we understand the importance of selecting the right components for your systems, which is why we offer a wide range of high-quality pilot relief valves. Whether you need the precision of the M4 or the durability of the M5, our expert team is here to help you find the ideal solution for your hydraulic system needs.