How to Troubleshoot Hydraulic Lift Valve Groups

How to Troubleshoot Hydraulic Lift Valve Groups

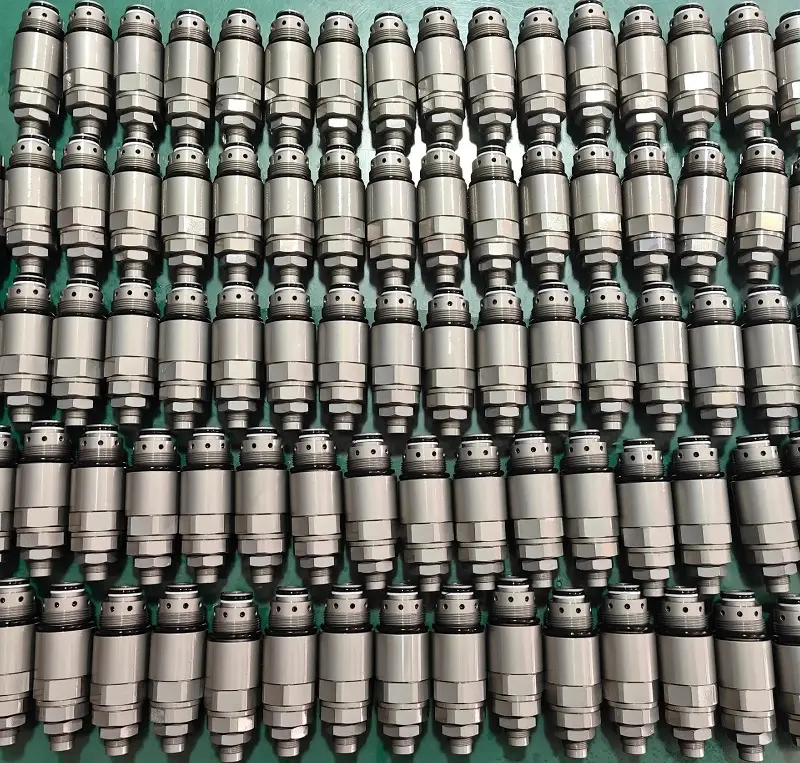

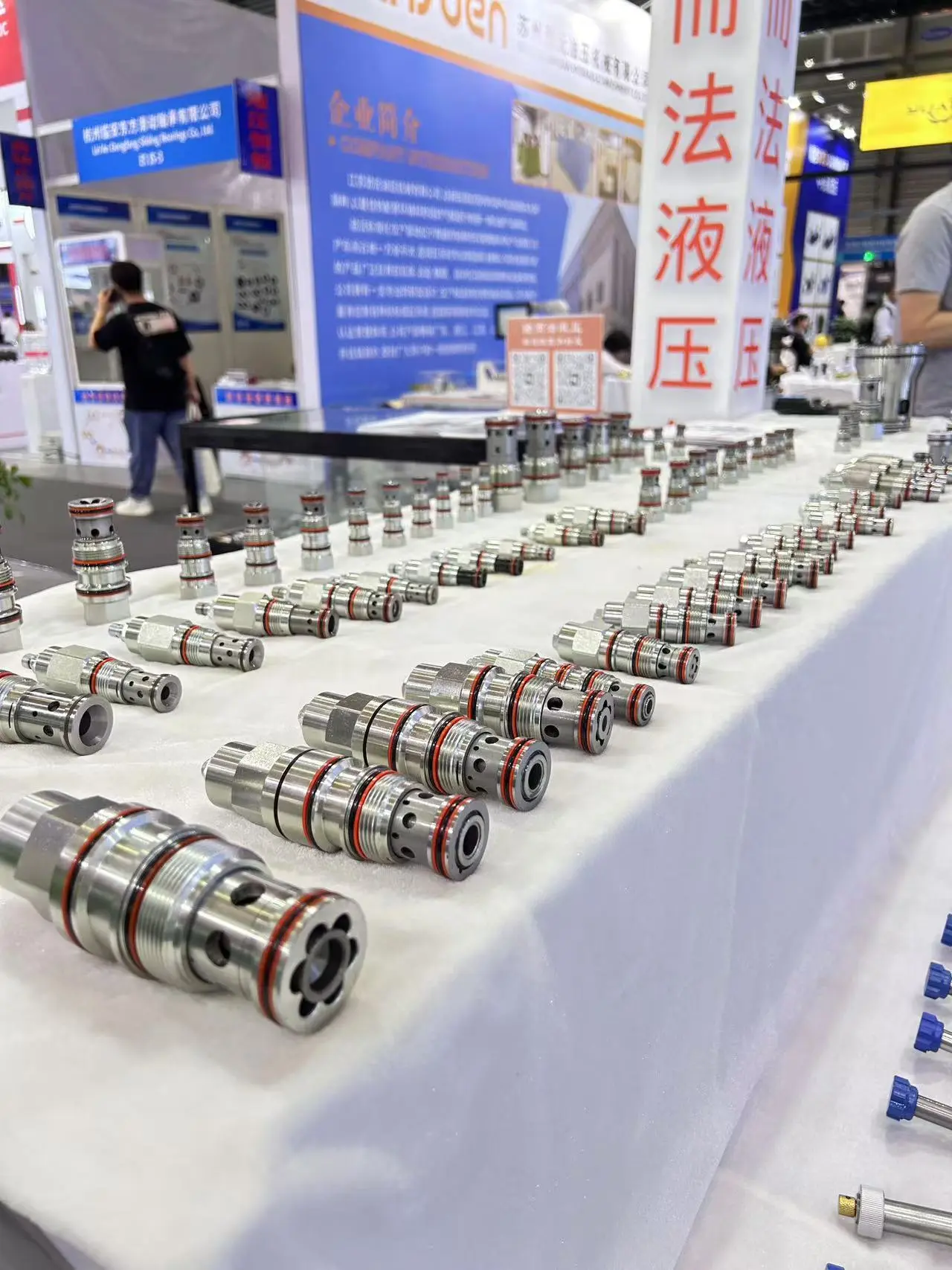

Hydraulic lift valve groups, or 液压升降阀组, play a pivotal role in machinery, ensuring stability and control in lifting applications. These components are essential for equipment like electric lifting platforms and scissor lifts. Effective troubleshooting of these valve groups is crucial to prevent downtime and costly repairs. Common issues, such as valve leakage or defective lowering valves, can lead to operational inefficiencies. By addressing these problems promptly, machinery can maintain optimal performance, thus extending the lifespan of the Hydraulic Systems and ensuring smooth operations.

Identifying Common Problems

Understanding the common problems associated with hydraulic lift valve groups, or 液压升降阀组, is essential for maintaining machinery efficiency. Recognizing symptoms early can prevent more severe issues and costly repairs.

Symptoms of Malfunction

Unusual Noises

Hydraulic systems should operate smoothly and quietly. When unusual noises occur, they often indicate a problem within the 液压升降阀组. These sounds might include knocking, hissing, or whining, suggesting issues like air in the system or component wear.

Slow or Erratic Movement

Machinery relying on hydraulic lift valve groups should move predictably and consistently. Slow or erratic movement can signal a malfunction. This symptom might result from inadequate hydraulic fluid flow or pressure inconsistencies within the system.

Leaks and Pressure Loss

Leaks in the hydraulic system lead to pressure loss, which can severely impact performance. Operators should regularly inspect for visible leaks around the 液压升降阀组. Pressure loss often accompanies leaks, reducing the system's ability to function effectively.

Potential Causes

Contaminated Hydraulic Fluid

Contaminated hydraulic fluid is a frequent cause of problems in hydraulic systems. Dirt, water, or other impurities can enter the fluid, affecting the performance of the 液压升降阀组. Regular fluid checks and replacements help mitigate this issue.

Worn or Damaged Seals

Seals within the hydraulic lift valve group play a crucial role in maintaining pressure and preventing leaks. Over time, these seals can wear out or become damaged, leading to inefficiencies. Regular inspection and timely replacement of seals are vital for optimal performance.

Blocked or Malfunctioning Valves

Valves within the 液压升降阀组 can become blocked or malfunction due to debris or mechanical failure. Such blockages hinder fluid flow and disrupt system operations. Routine maintenance and cleaning can prevent these issues, ensuring smooth valve function.

Step-by-Step Troubleshooting Guide

Troubleshooting hydraulic lift valve groups, or 液压升降阀组, requires a systematic approach to ensure machinery operates efficiently. This guide provides clear steps for identifying and resolving issues.

Initial Inspection

Visual Examination of Components

Technicians should begin by visually inspecting the components of the hydraulic lift valve group. Look for signs of wear, damage, or misalignment. Components like hoses, seals, and connectors should be intact and free from visible defects. Regular visual checks can prevent minor issues from escalating into major problems.

Checking Fluid Levels and Quality

Hydraulic systems rely heavily on fluid quality and levels. Low fluid levels can lead to inadequate pressure, while contaminated fluid can cause blockages and wear. Technicians should check the fluid reservoir for appropriate levels and inspect the fluid for clarity and absence of contaminants. Regular fluid checks are crucial for maintaining the performance of the 液压升降阀组.

Diagnostic Testing

Pressure Testing

Pressure testing helps identify leaks and pressure inconsistencies within the system. Technicians should use a pressure gauge to measure the system's pressure against the manufacturer's specifications. Any deviations might indicate leaks or blockages that need addressing. Consistent pressure testing ensures the hydraulic system operates within optimal parameters.

Flow Rate Analysis

Flow rate analysis involves measuring the hydraulic fluid's flow through the system. Technicians should use flow meters to assess whether the fluid moves at the correct rate. Deviations in flow rate can signal blockages or component malfunctions. Regular flow rate analysis helps maintain the efficiency of the 液压升降阀组.

Implementing Solutions

Cleaning and Replacing Filters

Filters play a vital role in preventing contaminants from entering the hydraulic system. Technicians should clean or replace filters regularly to ensure they function effectively. Clean filters help maintain fluid purity, reducing the risk of blockages and wear in the 液压升降阀组.

Repairing or Replacing Faulty Parts

When components show signs of wear or damage, technicians should repair or replace them promptly. This includes seals, valves, and hoses that may affect the system's performance. Timely repairs prevent further damage and ensure the hydraulic lift valve group operates smoothly.

Professional Insight: According to industry experts, regular maintenance and proactive troubleshooting are essential for the longevity and reliability of hydraulic systems. By following a structured approach, technicians can prevent costly downtime and extend the lifespan of machinery.

Preventive Maintenance Tips

Preventive maintenance plays a crucial role in ensuring the longevity and efficiency of hydraulic systems. By implementing regular checks and adhering to best practices, technicians can significantly reduce the risk of malfunctions in hydraulic lift valve groups, or 液压升降阀组.

Regular Inspection and Servicing

Scheduled Maintenance Checks

Technicians should establish a routine schedule for maintenance checks. These checks involve inspecting all components of the hydraulic system, including hoses, seals, and valves. Regular inspections help identify potential issues before they escalate into major problems. By adhering to a maintenance schedule, technicians ensure that the hydraulic lift valve group operates at peak performance.

Keeping a Maintenance Log

Maintaining a detailed log of all maintenance activities is essential. This log should include information about inspections, repairs, and replacements. A comprehensive maintenance log provides valuable insights into the system's history and helps track recurring issues. Technicians can use this information to make informed decisions about future maintenance needs.

Best Practices for Hydraulic Fluid Management

Using the Correct Fluid Type

Selecting the appropriate hydraulic fluid is vital for system performance. Different hydraulic systems require specific fluid types to function optimally. Technicians should consult the manufacturer's guidelines to ensure they use the correct fluid for the 液压升降阀组. Using the right fluid type minimizes wear and prevents potential damage to the system.

Monitoring Fluid Condition

Regular monitoring of hydraulic fluid condition is necessary to maintain system efficiency. Technicians should check for signs of contamination, such as discoloration or the presence of particles. Contaminated fluid can lead to blockages and reduce the effectiveness of the hydraulic lift valve group. By routinely assessing fluid condition, technicians can take corrective actions promptly.

Expert Testimony:

Unknown, an expert in hydraulic systems maintenance, emphasizes, "Proper preventative maintenance practices can help reduce the risk of these issues and prolong the lifespan of hydraulic pumps."

Implementing these preventive maintenance tips ensures that hydraulic systems remain reliable and efficient. By focusing on regular inspections and fluid management, technicians can extend the lifespan of the 液压升降阀组 and maintain optimal system performance.

Regular troubleshooting and maintenance of hydraulic lift valve groups, or 液压升降阀组, are essential for preventing major breakdowns and ensuring efficient operation. Proactive measures, such as scheduled inspections and fluid management, significantly extend the lifespan of these systems. By maintaining optimal performance, operators can avoid costly repairs and downtime. Proper maintenance not only enhances reliability but also ensures the safety and serviceability of machinery. Embracing these practices leads to long-term benefits, keeping hydraulic systems running smoothly and effectively.