How Hydraulic Cartridge Valves Enhance Performance in Agricultural Machinery

Understanding Hydraulic Cartridge Valves

Hydraulic cartridge valves are compact, modular components that are installed inside a valve cavity or manifold block. These valves regulate flow, pressure, and direction of hydraulic fluid in a system. Cartridge valves can include check valves, Relief Valves, flow control valves, solenoid valves, and proportional valves, among others.

What sets Cartridge Valves apart from traditional valve configurations is their space-saving design, flexibility, and serviceability. Instead of being installed externally in line, cartridge valves are embedded directly into hydraulic manifolds, resulting in cleaner system layouts, reduced leak points, and improved maintenance access.

The Role of Hydraulic Systems in Agricultural Machinery

Before we delve deeper into the advantages of cartridge valves, it's important to understand the role of hydraulics in agricultural applications. Hydraulic systems are used extensively in a wide range of machinery such as:

-

Tractors

-

Combine harvesters

-

Seed drills

-

Sprayers

-

Balers

-

Ploughs and cultivators

-

Loaders and backhoes

These machines rely on hydraulic power to perform essential functions such as lifting, rotating, pushing, steering, braking, and fine-tuned control of implements. Reliable hydraulic components are the backbone of these systems, and even a minor malfunction can lead to significant downtime during peak agricultural seasons.

How Cartridge Valves Improve Agricultural Machinery Performance

Here are some of the key ways in which hydraulic cartridge valves enhance the performance and reliability of agricultural machinery:

1. Compact and Modular Design

Space constraints are a common challenge in agricultural equipment design. Manufacturers seek to pack more power and functionality into smaller footprints. Cartridge valves are ideal for this purpose because of their modular design and ability to be housed in compact manifolds.

By integrating multiple functions into a single hydraulic block using cartridge valves, engineers can reduce the size and complexity of the overall hydraulic system. This results in lighter machinery, improved weight distribution, and easier component layout—all of which contribute to better fuel efficiency and maneuverability in the field.

2. Improved Serviceability and Reduced Downtime

Cartridge valves are designed for quick replacement and servicing. In the event of a failure, the valve can be easily removed from its cavity without disconnecting multiple hoses or disassembling larger hydraulic assemblies. This feature is particularly valuable in agricultural settings, where equipment downtime can result in delayed planting or harvesting schedules.

The ease of maintenance translates to faster repairs, less skilled labor required for valve replacement, and lower overall maintenance costs. For fleet operators and farmers, this means greater uptime and a better return on investment.

3. High Pressure and Flow Capabilities

Agricultural equipment often operates under demanding conditions, including high loads, fluctuating pressures, and variable flow requirements. Longerfa's hydraulic cartridge valves are designed to handle high-pressure applications—often up to 350 bar (5000 psi)—and offer excellent flow characteristics even in compact configurations.

This ensures optimal power transmission to implements and attachments, whether it's lifting a heavy plow, operating a hydraulic cylinder on a baler, or driving a sprayer boom. The precise control of flow and pressure contributes to smoother operation and less strain on mechanical components.

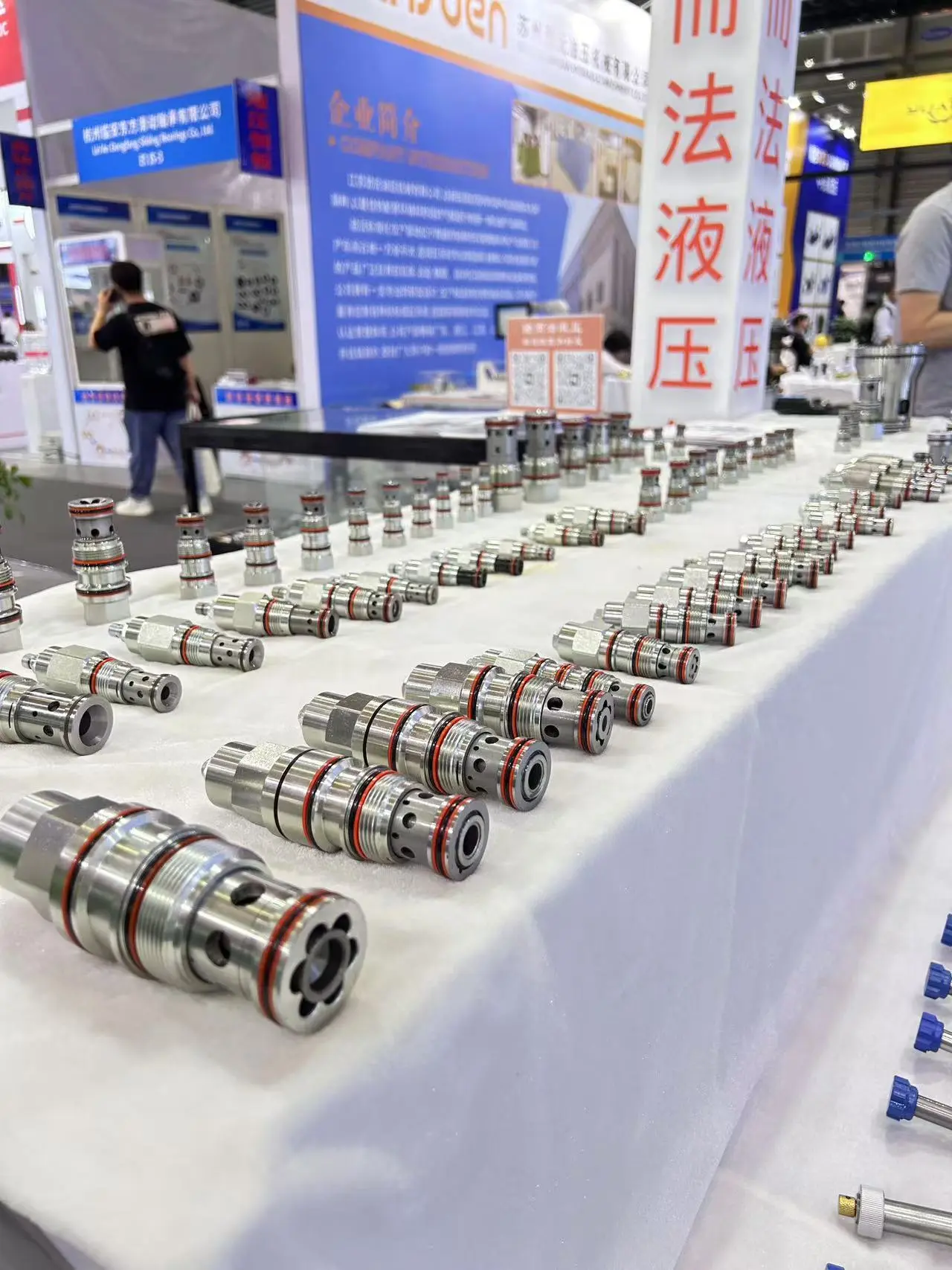

4. Customization and Flexibility

Each agricultural application has unique hydraulic requirements. At Ningbo Longerfa, we provide customized cartridge valve solutions tailored to specific machinery platforms. Our engineering team collaborates with OEMs and system designers to deliver bespoke valves with the right flow coefficients, pressure settings, and control features.

From load-holding valves to pressure compensators and directional solenoids, we offer a wide variety of configurations that enable machinery to operate at peak performance under different field conditions. The flexibility to modify or upgrade cartridge valves also means future-proofing your system against changing demands.

5. Enhanced Safety and Control

Safety is a critical concern in modern agriculture. Cartridge valves contribute to safer operation by offering features such as:

-

Load holding and over-center functions to prevent unintended movement of implements.

-

Pressure relief and anti-cavitation mechanisms to protect pumps and actuators.

-

Smooth start-stop control to reduce mechanical shocks during operation.

Longerfa’s precision-engineered cartridge valves are thoroughly tested to ensure consistent performance, accurate response times, and safe integration with hydraulic circuits.

6. Energy Efficiency and Sustainability

As global agriculture shifts toward sustainability, energy efficiency is becoming increasingly important. Hydraulic cartridge valves help improve energy efficiency by reducing internal leakage, optimizing flow paths, and supporting advanced control strategies like load sensing.

By incorporating electro-hydraulic or proportional cartridge valves, machines can automatically adjust flow and pressure based on real-time demand—minimizing fuel consumption and extending the life of hydraulic components. In turn, this supports environmental goals and helps operators lower their operational carbon footprint.

Real-World Applications in Agricultural Equipment

Let’s take a closer look at how hydraulic cartridge valves are being used in the field:

-

Seeders and Planters: Cartridge flow control valves regulate the precise dispensing of seeds and fertilizers, improving yield efficiency.

-

Harvesters: Directional valves control the motion of cutting blades, conveyors, and grain tank augers.

-

Sprayers: Pressure relief and check valves maintain consistent spray patterns and prevent backflow contamination.

-

Tractors: Load-holding valves support the safe lifting and lowering of implements while pressure compensators balance flow to auxiliary hydraulic tools.

These examples highlight the indispensable role cartridge valves play in optimizing machinery performance and reducing operating risks.

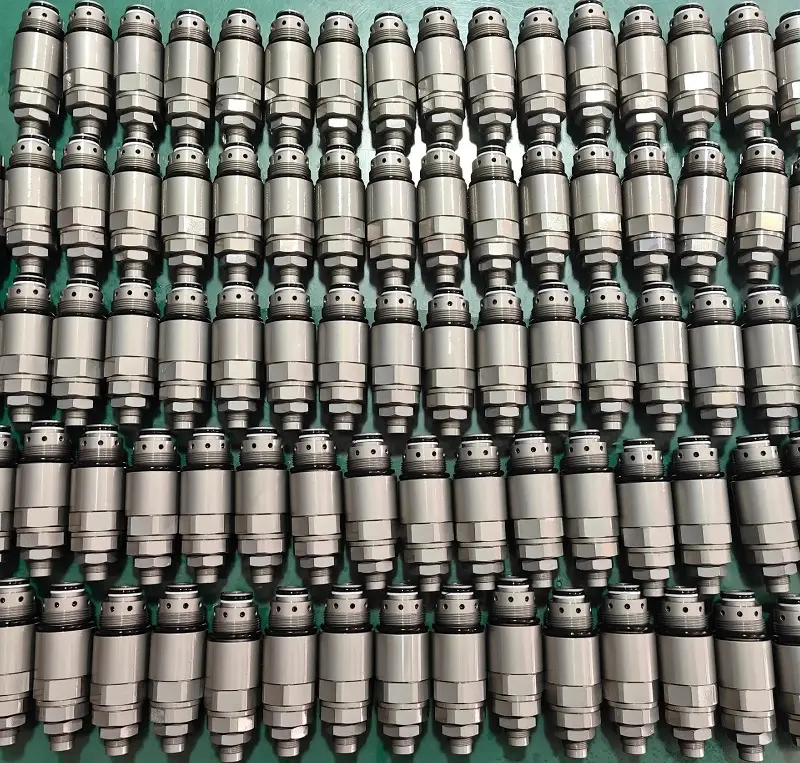

Commitment to Quality at Ningbo Longerfa

At Ningbo Longerfa Hydraulic Co., Ltd., our commitment to excellence drives everything we do. Our hydraulic cartridge valves are manufactured using high-grade materials, CNC-machined components, and rigorous quality assurance protocols. Each valve undergoes comprehensive testing for pressure tolerance, leakage, temperature resistance, and performance reliability.

With decades of experience serving the agricultural, construction, and industrial sectors, we understand the unique challenges our customers face. That’s why we continue to invest in R&D, advanced manufacturing, and customer-focused innovation to deliver superior hydraulic solutions.

Looking Ahead

As agricultural equipment continues to evolve with smart controls, automation, and electrification, hydraulic cartridge valves will remain at the heart of efficient fluid power systems. Their adaptability, reliability, and performance advantages make them essential components in future-ready machinery.

Whether you are an OEM designing the next generation of harvesters, a farm equipment distributor, or a service technician seeking dependable components, Longerfa’s hydraulic cartridge valves are engineered to deliver the performance you need—when and where it matters most.