Expert Guide: DH55/DH60 Rotary Valve Disassembly, Reassembly & Seal Replacement– Longerfa Hydraulic’s Professional Maintenance Solution for Industrial Valves

Section 1: DH55/DH60 Rotary Valve Disassembly Procedure

1.1 Safety Precautions & Preparation

✅ Depressurize the Hydraulic System – Release all residual pressure before disassembly.

✅ Wear PPE – Safety goggles, gloves, and protective clothing to prevent fluid exposure.

✅ Clean work area – Prevent contamination of internal components.

1.2 Tools & Equipment Required

-

Torque wrench (for precise bolt tightening)

-

Hex key set (metric/standard, depending on valve model)

-

Hydraulic line disconnect tools

-

Seal removal picks (non-metallic to avoid scratches)

-

Clean, lint-free rags & hydraulic fluid-compatible solvent

1.3 Step-by-Step Disassembly

-

Isolate the valve – Shut off hydraulic power and disconnect hoses.

-

Remove mounting bolts – Loosen bolts in a crisscross pattern to avoid warping.

-

Separate valve housing – Gently pry open using a plastic wedge to protect sealing surfaces.

-

Extract internal components – Carefully remove the spool, springs, and bearings, keeping them in order.

-

Inspect for wear – Check for scoring, corrosion, or excessive wear on the spool and valve body.

Section 2: DH55/DH60 Seal Replacement Guide

2.1 Signs of Seal Failure

⚠ External leakage (fluid around valve body)

⚠ Stiff or erratic valve operation (indicating friction from worn seals)

⚠ Contaminated hydraulic fluid (seal debris in the system)

2.2 Removing Old Seals

-

Use a plastic seal pick to avoid damaging grooves.

-

Clean seal grooves thoroughly with a solvent before installing new seals.

2.3 Installing New Seals (Longerfa Genuine Seal Kit Recommended)

-

Apply hydraulic-compatible lubricant to new O-rings and backup rings.

-

Install seals carefully – Ensure they are seated properly without twisting.

-

Verify seal orientation – Some seals (e.g., U-cups) have directional installation requirements.

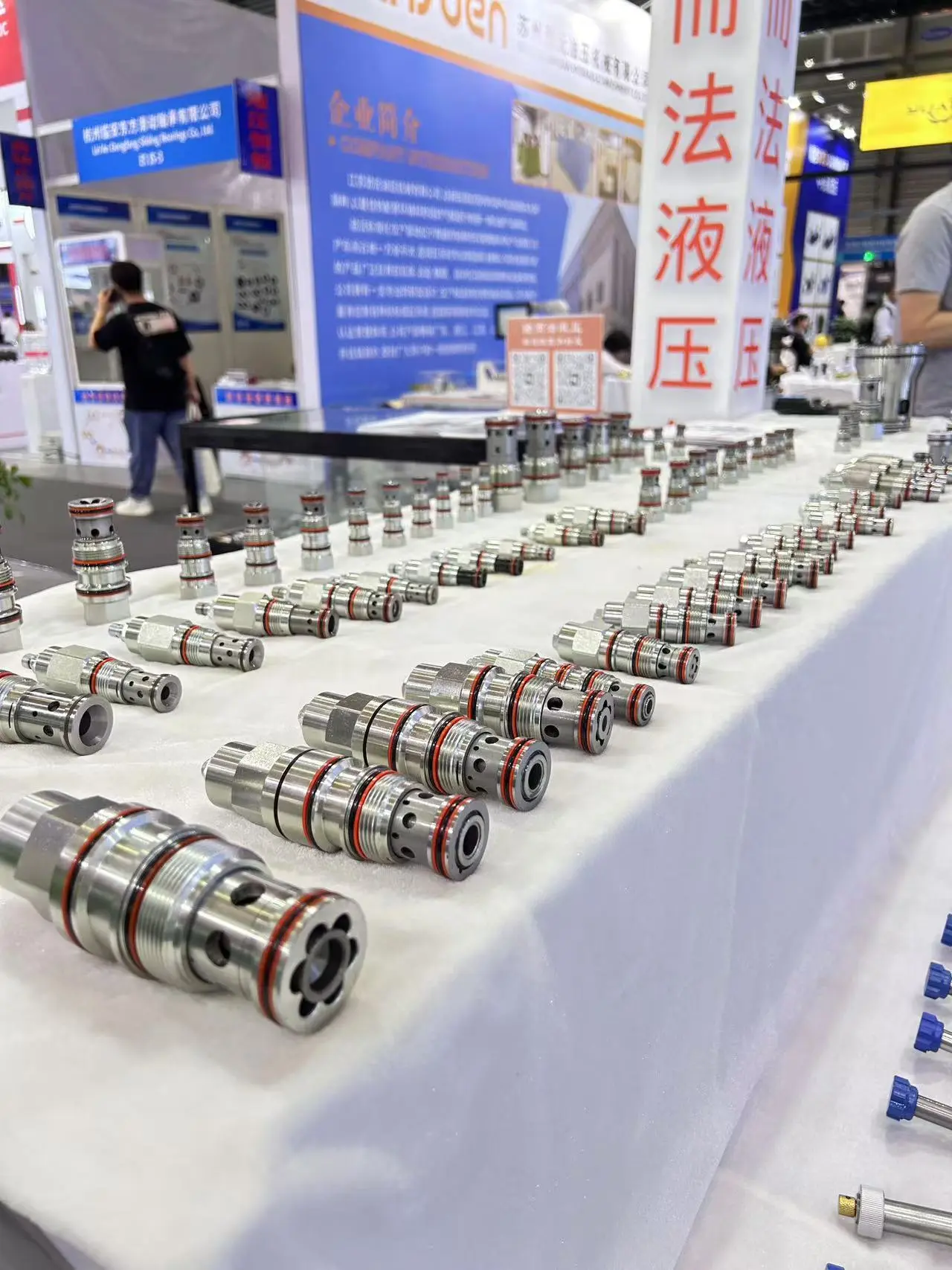

2.4 Longerfa’s Premium Seal Kits

✔ High-grade Nitrile (NBR) or Fluorocarbon (FKM) materials for superior durability.

✔ Precision-molded for exact fitment in DH55/DH60 valves.

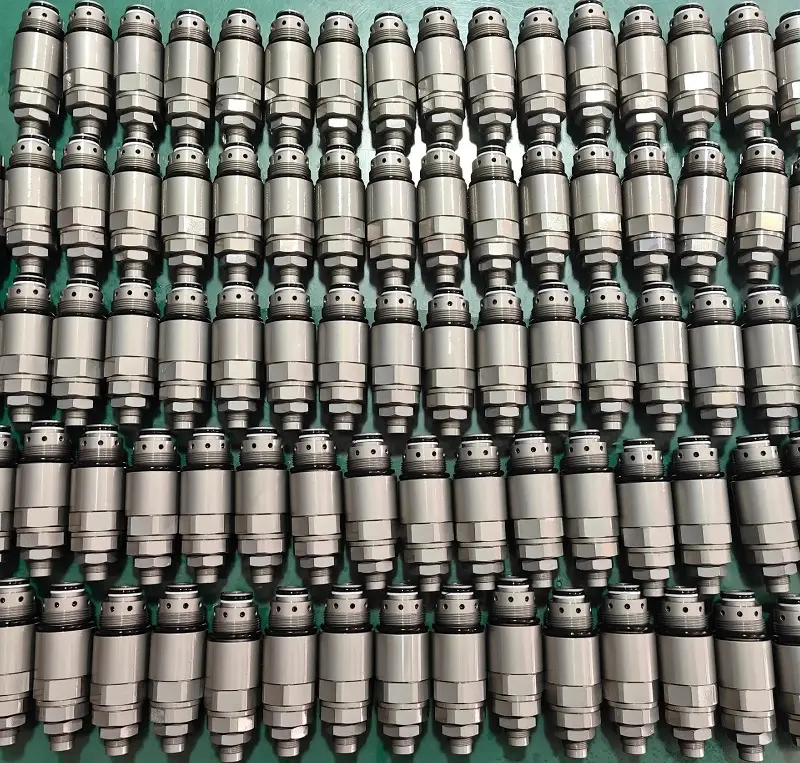

✔ Available in bulk for fleet maintenance – Reduce downtime with ready spares.

Section 3: Reassembling the DH55/DH60 Rotary Valve

-

Reinstall internal components in reverse order of disassembly.

-

Lubricate moving parts with clean hydraulic fluid before reassembly.

-

Tighten housing bolts evenly (refer to torque specs in the manual).

-

Reconnect hydraulic lines and perform a pressure test to check for leaks.

Why Choose Longerfa Hydraulic for Your Valve Maintenance Needs?

🔧 OEM-Quality replacement parts – Precision-engineered for perfect compatibility.

🔧 Global Technical Support – Expert assistance for complex Hydraulic Systems.

🔧 Fast Shipping & Inventory Availability – Minimize equipment downtime.

Upgrade your maintenance process with Longerfa’s professional-grade solutions!

Featured Image: Technician Replacing Seals on a DH55 Rotary Valve

*(High-resolution image showing a technician using proper tools to install seals in a DH55 valve, emphasizing correct handling techniques.)*

Conclusion

Proper maintenance of DH55/DH60 rotary valves ensures longer service life, reduced fluid leaks, and optimal hydraulic performance. By following this guide and using Longerfa Hydraulic’s genuine seal kits, you can maintain peak efficiency in your machinery.

📞 Contact our engineering team today for customized support!

🔗 Explore our full range of hydraulic valves and spare parts at www.longerfahydraulic.com