Don’t Miss This Kawasaki Valve Comparison Guide

Choosing the appropriate KawasakiTravel Motor Control Valve is essential for keeping your machinery running at optimal performance. It’s important to consider factors such as performance, compatibility, durability, and cost, as these directly influence how effectively your equipment operates in challenging conditions. This guide is designed to help you evaluate different KawasakiTravel Motor Control Valve models and make well-informed decisions tailored to your unique requirements.

Key Takeaways

- Focus on performance and efficiency when picking a Kawasaki valve. Better models make machines work faster and use less energy.

- Check if it works with your travel motors. Picking a valve that fits well avoids problems and damage.

- Think about strength and quality. Strong valves last longer and need fewer repairs, saving money.

Overview of Kawasaki Travel Motor Control Valves

What Are Travel Motor Control Valves?

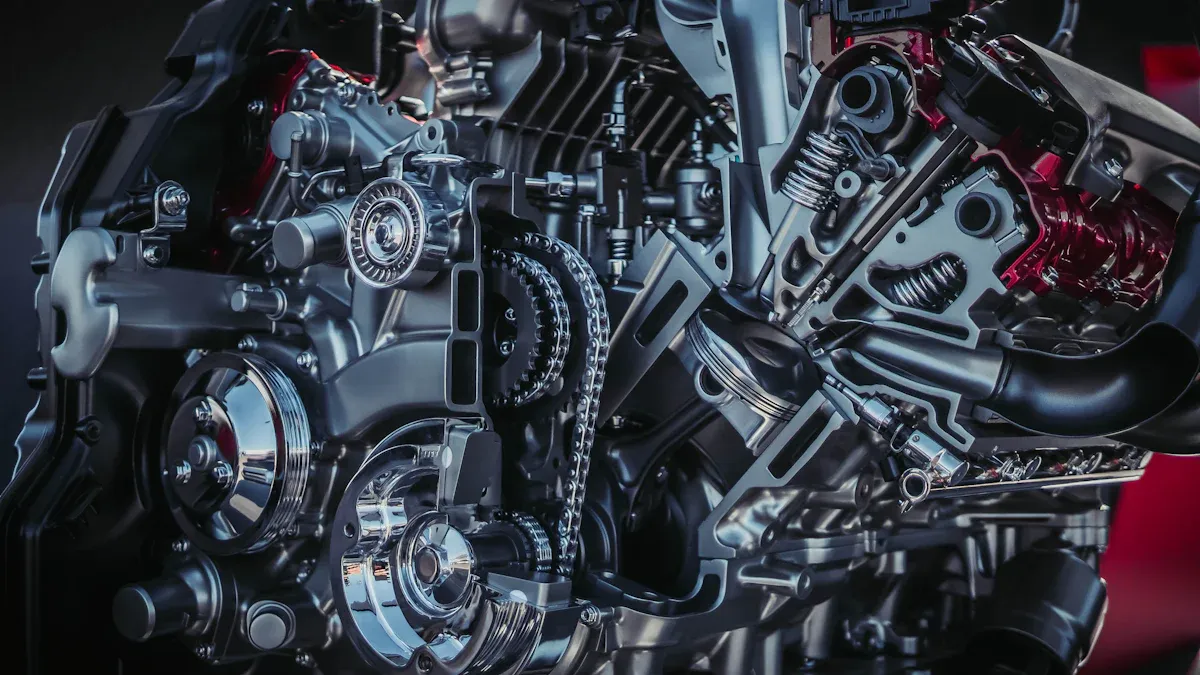

Travel motor control valvesare critical components in Hydraulic Systems, particularly in heavy machinery such as excavators, loaders, and cranes. These valves regulate the flow of hydraulic fluid to the travel motors, ensuring precise control over speed, direction, and torque. By managing the hydraulic pressure, they enable smooth and efficient operation, even under demanding conditions.

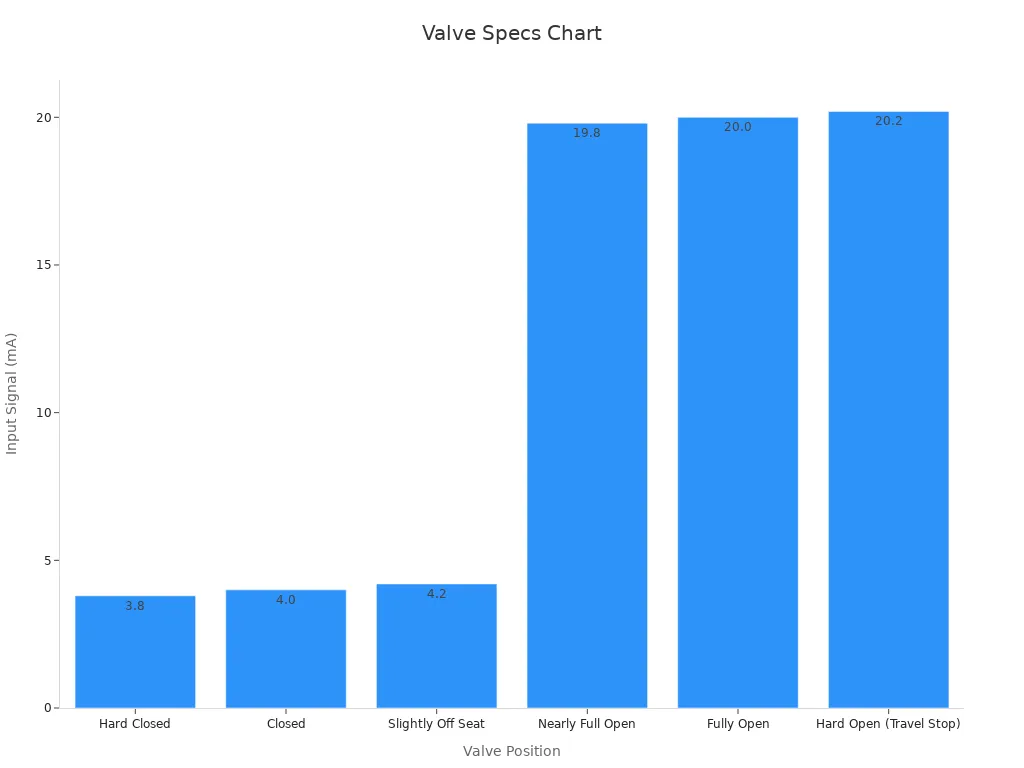

The technical specifications of these valves highlight their precision. For instance, the valve position changes based on the input signal, as shown below:

| Input Signal (mA) | Valve Position |

|---|---|

| 3.8 | Hard Closed |

| 4.0 | Closed |

| 4.2 | Slightly Off Seat |

| 19.8 | Nearly Full Open |

| 20.0 | Fully Open |

| 20.2 | Hard Open (Travel Stop) |

This level of control ensures that your machinery operates with optimal efficiency and reliability.

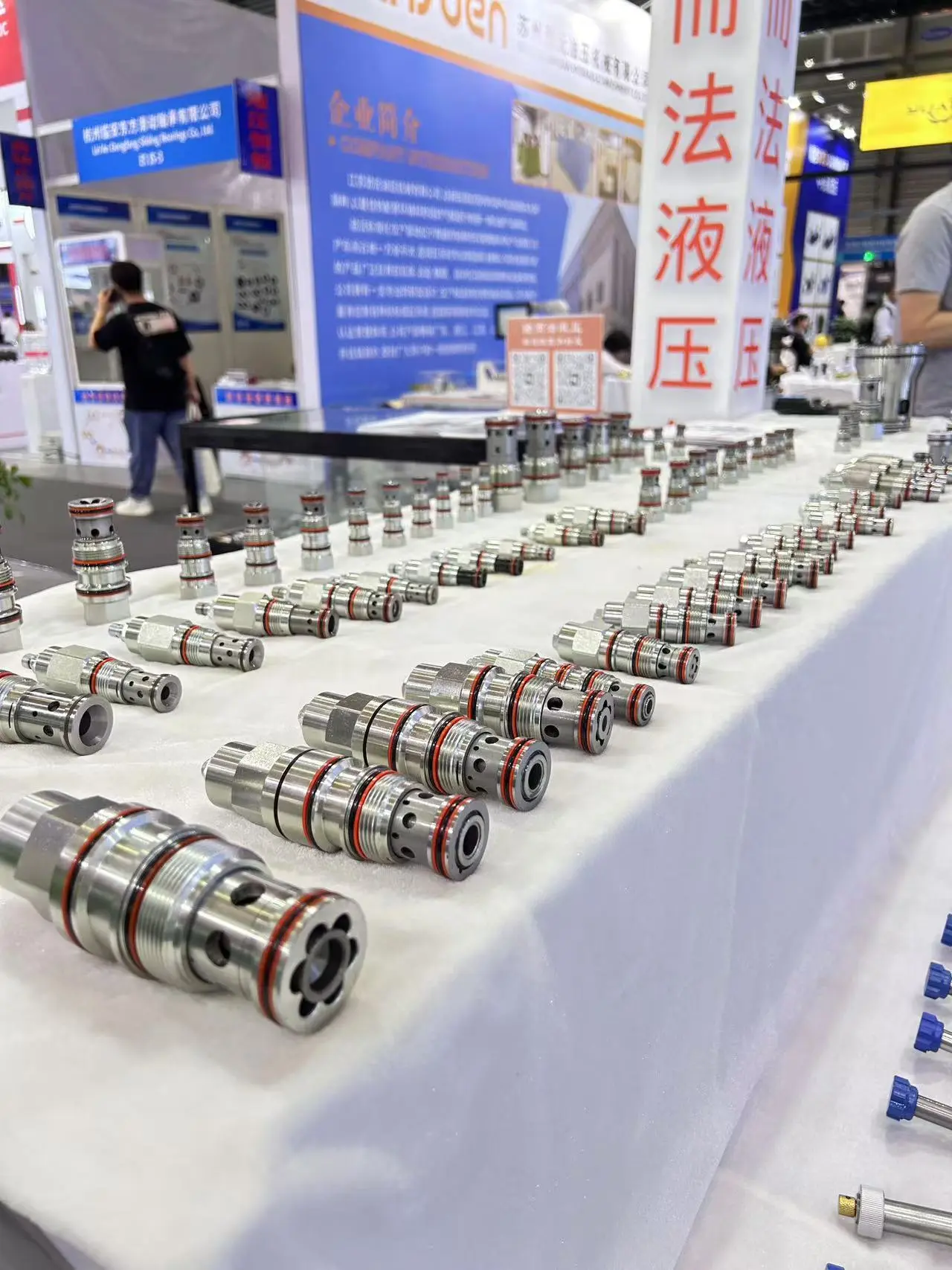

Why Choose Kawasaki for Travel Motor Control Valves?

Kawasaki has established itself as a leader in the hydraulic systems market, offering innovative and reliable solutions. Their travel motor control valves are renowned for their durability, precision, and compatibility with a wide range of machinery. Customers consistently praise Kawasaki for their ability to reduce maintenance costs and improve operational efficiency.

- Mr. Arita from Showa Denko K.K. noted that predictive maintenance enabled by Kawasaki valves stabilizes operations and reduces costs.

- Junichi Yoshitake highlighted how Kawasaki's maintenance support system prevents disruptions by identifying hidden issues.

Market trends further emphasize Kawasaki's dominance. In the Asia Pacific region, the demand for advanced hydraulic systems is growing at a CAGR of 6.2%, driven by rapid industrialization and infrastructure investments. North America and Europe also show strong growth, with CAGRs of 5.0% and 4.8%, respectively, due to modernization efforts and advancements in manufacturing technologies.

| Region | Projected CAGR | Key Drivers |

|---|---|---|

| Asia Pacific | 6.2% | Rapid industrialization, investments in infrastructure, growth in manufacturing, construction, and agriculture sectors. |

| North America | 5.0% | R&D activities, modernization of industrial systems, focus on energy efficiency and sustainability. |

| Europe | 4.8% | Demand for advanced fluid control systems, investments in renewable energy, advancements in manufacturing and automotive technologies. |

By choosing Kawasaki, you gain access to cutting-edge technology and a proven track record of excellence in hydraulic systems.

Key Factors to Compare Kawasaki Valve Models

Performance and Efficiency

When evaluating Kawasaki Travel Motor Control Valve models, performance and efficiency should be your top priorities. These valves regulate hydraulic fluid flow with precision, ensuring smooth operation even under high-pressure conditions. Models with advanced flow control mechanisms can enhance your machinery's responsiveness and reduce energy consumption. For example, valves with optimized internal designs minimize fluid resistance, improving overall system efficiency. Choosing a high-performance valve can significantly boost productivity and reduce downtime.

Compatibility with Travel Motors

Not all valves are compatible with every travel motor. Ensuring compatibility is crucial to avoid operational inefficiencies or potential damage. Kawasaki valves undergo rigorous engineering tests to confirm their suitability for various travel motors. For instance, the Auto-Ignition Temperature (AIT) Test evaluates how materials perform under high-pressure oxygen environments, ensuring safety and reliability.

| Test Name | Purpose |

|---|---|

| Auto-Ignition Temperature (AIT) Test | Determines the temperature at which a material auto-ignites in high-pressure oxygen environments. |

By selecting a valve tested for compatibility, you can ensure seamless integration with your machinery.

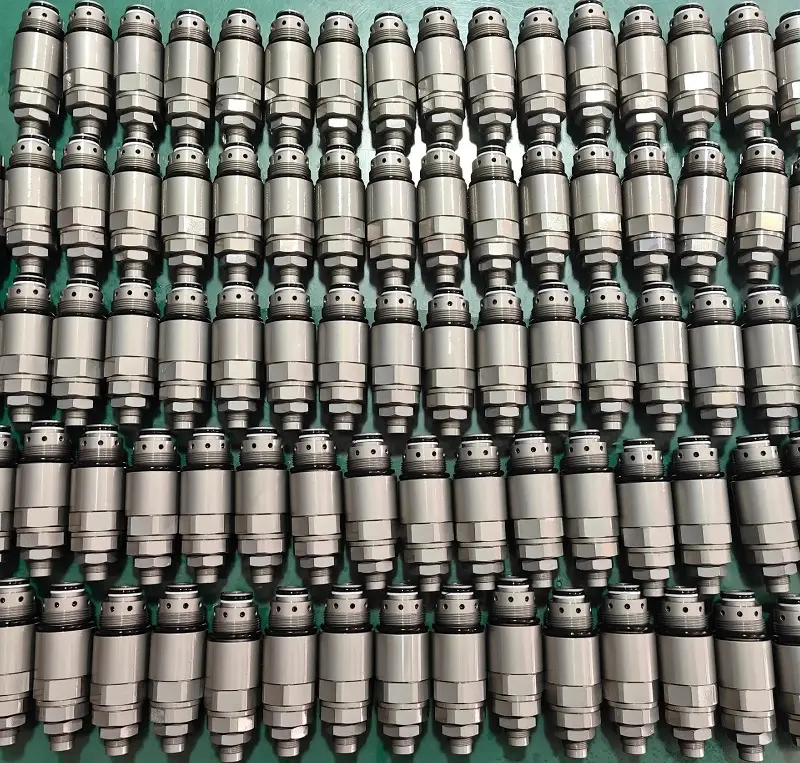

Durability and Build Quality

Durability plays a vital role in the long-term performance of hydraulic systems. Kawasaki valves are known for their robust construction and resistance to wear and tear. High-quality materials and precision engineering ensure these valves withstand harsh operating conditions. Investing in a durable valve reduces the frequency of replacements and minimizes maintenance costs, making it a cost-effective choice for heavy-duty applications.

Cost and Value for Money

Cost is often a deciding factor when comparing valve models. However, focusing solely on price can lead to compromises in performance or durability. Kawasaki employs various pricing strategies to offer value for money. For instance, value-based pricing highlights operational cost savings through reduced maintenance and energy efficiency.

| Pricing Trend/Strategy | Description |

|---|---|

| Dynamic Pricing Models | Manufacturers are adopting dynamic pricing to remain competitive against advanced technologies. |

| Value-Based Pricing | Pricing is linked to operational cost savings, emphasizing reduced maintenance and energy efficiency. |

| Tiered Pricing Structures | Separates base costs from optional features, allowing for better cost comparison. |

By understanding these pricing strategies, you can choose a valve that balances cost with long-term benefits.

Comparison of Popular Kawasaki Valve Models

K3X63: Features and Applications

The K3X63 valve is a compact yet powerful option designed for mid-sized machinery. Its lightweight construction makes it ideal for applications where weight reduction is critical. You will find this model particularly effective in excavators and small loaders due to its precise flow control and energy efficiency.

Key Features:

- Flow rate: 63 liters per minute

- Compact design for easy installation

- High responsiveness for improved machine control

Applications:

- Excavators

- Small construction equipment

- Agricultural machinery

Tip: If you prioritize energy efficiency and compactness, the K3X63 is an excellent choice for your hydraulic system.

K3X80: Features and Applications

The K3X80 valve offers enhanced flow capacity, making it suitable for larger machinery. Its robust design ensures durability in demanding environments. This model excels in applications requiring consistent performance under high pressure.

Key Features:

- Flow rate: 80 liters per minute

- Durable construction for heavy-duty use

- Optimized for high-pressure systems

Applications:

- Medium-sized excavators

- Forestry equipment

- Industrial machinery

Note: The K3X80 is a reliable option if your machinery operates in harsh conditions and requires a higher flow rate.

M2X63: Features and Applications

The M2X63 valve combines precision and versatility. Its advanced control mechanisms allow for smooth operation, even in complex hydraulic systems. You will appreciate its adaptability across various types of machinery.

Key Features:

- Flow rate: 63 liters per minute

- Advanced control for precise operation

- Versatile design for multiple applications

Applications:

- Compact excavators

- Material handling equipment

- Utility vehicles

Insight: The M2X63 is perfect for operators seeking a balance between precision and versatility.

M5X130: Features and Applications

The M5X130 valve is engineered for heavy-duty applications. Its high flow capacity and robust build make it a top choice for large-scale machinery. This model ensures reliable performance, even under extreme workloads.

Key Features:

- Flow rate: 130 liters per minute

- Heavy-duty construction for maximum durability

- High efficiency under heavy loads

Applications:

- Large excavators

- Mining equipment

- Heavy construction machinery

Recommendation: Choose the M5X130 if your operations demand high flow rates and exceptional durability.

M5X180: Features and Applications

The M5X180 valve is designed for maximum performance in the most demanding environments. Its superior flow capacity supports large-scale operations with ease. You will benefit from its ability to handle extreme pressures without compromising efficiency.

Key Features:

- Flow rate: 180 liters per minute

- Exceptional pressure handling capabilities

- Designed for large-scale operations

Applications:

- Mining machinery

- Large industrial equipment

- Specialized construction vehicles

Advice: The M5X180 is ideal for operations requiring peak performance and reliability.

MCB195: Features and Applications

The MCB195 valve stands out for its innovative design and advanced features. Its unique construction enhances system efficiency while reducing energy consumption. This model is well-suited for applications where precision and sustainability are priorities.

Key Features:

- Flow rate: 195 liters per minute

- Energy-efficient design

- Advanced control mechanisms

Applications:

- Renewable energy systems

- High-precision industrial equipment

- Specialized agricultural machinery

Pro Tip: Opt for the MCB195 if you value energy efficiency and cutting-edge technology.

M2X210: Features and Applications

The M2X210 valve is a powerhouse designed for the most demanding tasks. Its high flow rate and robust construction make it a reliable choice for heavy-duty applications. You will appreciate its ability to maintain performance under extreme conditions.

Key Features:

- Flow rate: 210 liters per minute

- Built for extreme durability

- Optimized for heavy-duty tasks

Applications:

- Large-scale mining operations

- Heavy industrial machinery

- Specialized construction equipment

Suggestion: The M2X210 is the go-to option for operators handling the toughest jobs.

K3X90: Features and Applications

The K3X90 valve offers a balance between performance and efficiency. Its moderate flow rate makes it suitable for a wide range of applications. You will find this model particularly effective in medium-sized machinery.

Key Features:

- Flow rate: 90 liters per minute

- Balanced design for versatile use

- Reliable performance in various conditions

Applications:

- Medium-sized excavators

- Forestry equipment

- Utility vehicles

Tip: The K3X90 is a versatile choice for operators seeking a balance between cost and performance.

K3X112: Features and Applications

The K3X112 valve is designed for operators who need enhanced flow capacity without compromising efficiency. Its robust construction ensures long-term reliability, even in challenging environments.

Key Features:

- Flow rate: 112 liters per minute

- Durable design for extended lifespan

- High efficiency under varying conditions

Applications:

- Large excavators

- Industrial equipment

- Specialized forestry machinery

Advice: The K3X112 is an excellent option for applications requiring both power and durability.

Choosing the Right Kawasaki Valve for Your Needs

Best Models for Heavy-Duty Applications

For heavy-duty applications, you need a valve that can handle extreme workloads and maintain consistent performance. Models like the M5X130 and M2X210 excel in these scenarios. The M5X130 offers a flow rate of 130 liters per minute and is built for maximum durability, making it ideal for large excavators and mining equipment. Similarly, the M2X210, with its impressive 210 liters per minute flow rate, is perfect for large-scale operations requiring robust performance under challenging conditions.

These models are engineered to withstand high pressures and demanding environments, ensuring your machinery operates efficiently. Their heavy-duty construction reduces the risk of breakdowns, minimizing downtime and maintenance costs. If your operations involve mining, industrial machinery, or large construction projects, these valves provide the reliability and power you need.

Best Models for Cost-Effectiveness

Cost-effectiveness is crucial when balancing performance and budget. Models like the K3X63 and K3X90 stand out for their affordability and efficiency. The K3X63, with its compact design and 63 liters per minute flow rate, is ideal for small to mid-sized machinery. It delivers precise control while keeping energy consumption low. The K3X90, offering a moderate flow rate of 90 liters per minute, provides versatility across various applications without compromising on quality.

Cost-saving strategies, such as contracting services for parts production or licensing designs, align with the affordability of these models. By choosing these valves, you can achieve operational efficiency without overspending, making them a smart choice for small manufacturers or businesses with budget constraints.

Best Models for Long-Term Durability

Durability ensures your investment lasts for years. Models like the M5X180 and K3X112 are designed for long-term reliability. The M5X180, with its exceptional pressure-handling capabilities and 180 liters per minute flow rate, is built for demanding environments. The K3X112, offering a flow rate of 112 liters per minute, combines robust construction with high efficiency, making it suitable for industrial and forestry applications.

Long-term usage studies highlight the importance of proper maintenance for extending valve lifespan. For example, timely inspections and care can help valves like the M5X180 and K3X112 maintain peak performance for over 100,000 miles of operation. Investing in these models reduces replacement frequency and ensures consistent performance over time.

Kawasaki offers a diverse range of travel motor control valves, each tailored to specific needs. Models like the M5X130 excel in heavy-duty tasks, while the K3X63 provides cost-effective solutions for smaller machinery. For long-term durability, the M5X180 stands out with its robust design.

Tip: Assess your machinery's requirements carefully. Consider factors like workload, budget, and maintenance needs. Consulting with a hydraulic systems expert can help you make the best choice for your operations.

FAQ

What factors should you prioritize when selecting a Kawasaki valve?

Focus on performance, compatibility, durability, and cost. These factors ensure your machinery operates efficiently and minimizes maintenance needs.

How do you determine the right valve for heavy-duty applications?

Choose models like the M5X130 or M2X210. These valves handle extreme workloads, ensuring consistent performance in demanding environments.

Are Kawasaki valves compatible with all travel motors?

Not all valves fit every motor. Verify compatibility by consulting product specifications or seeking expert advice to avoid operational inefficiencies.

Tip: Always cross-check your machinery's requirements with the valve's technical specifications for optimal performance.