Applications of Hydraulic Cartridge Valves in Mining Equipment

Understanding Hydraulic Cartridge Valves

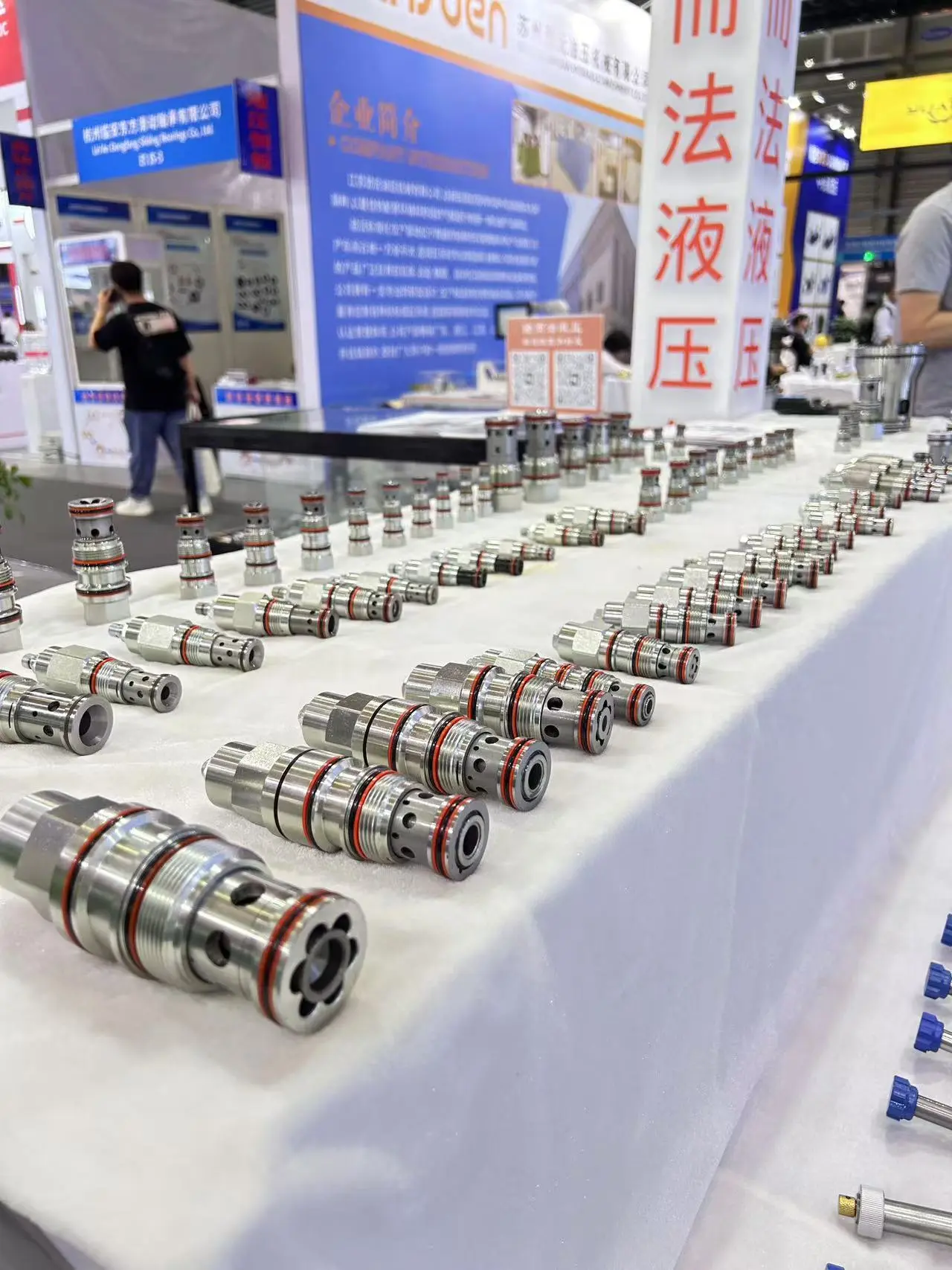

Hydraulic cartridge valves are modular components installed into standardized cavities within Hydraulic Manifolds. These valves regulate, control, or direct the flow and pressure of hydraulic fluid in machinery. Cartridge valves come in a variety of configurations, including:

-

Pressure control valves (e.g., relief, reducing, sequencing)

-

Directional Control Valves

-

Flow control valves

What makes them particularly valuable in mining equipment is their compact size, modularity, and ease of replacement or customization. These features support flexible system design and streamlined maintenance—essential characteristics for the rugged environments of mining sites.

Key Applications in Mining Equipment

1. Excavators and Loaders

Hydraulic cartridge valves are extensively used in large mining excavators and wheel loaders. These machines require precise flow and pressure control to operate their arms, buckets, booms, and other attachments. Cartridge valves such as main relief valves and auxiliary pressure control valves regulate hydraulic forces to ensure safe, smooth, and responsive motion.

At Ningbo Longerfa, we offer a full range of excavator relief valves designed for high-load operations, with excellent thermal stability and pressure responsiveness. Our valves maintain consistent performance even under fluctuating temperatures and pressures commonly encountered in mining sites.

2. Drill Rigs and Boring Machines

In rotary and percussive drilling machines, hydraulic systems drive the rotation and thrust mechanisms. Cartridge valves are integrated into the drill head and feed system to:

-

Control drill bit speed and torque

-

Manage return flow and prevent overpressure

-

Enhance drilling accuracy

Pressure-reducing valves, flow dividers, and pilot-operated relief valves from Longerfa’s lineup are engineered to deliver stable control during high-frequency, high-pressure operation. This contributes to higher drilling precision and reduced wear on the system.

3. Haul Trucks and Dumpers

Massive mining dump trucks rely on hydraulic systems for braking, suspension, and body hoisting operations. Cartridge valves are used to:

-

Regulate dump body lift and lower cycles

-

Protect the system from pressure surges

-

Maintain optimal ride height and suspension control

Given the massive size and weight of these vehicles, safety is paramount. Longerfa’s hydraulic cartridge valves are built to withstand high shock loads, vibration, and thermal cycling, making them ideal for use in mining haulage equipment.

4. Continuous Miners and Shuttle Cars

Underground mining machinery such as continuous miners and shuttle cars are equipped with compact hydraulic circuits that demand space-saving valve solutions. Cartridge valves help in controlling traction, conveyor systems, and cutter heads.

Longerfa’s compact cartridge valve solutions integrate multiple functions into a single manifold block, reducing the total number of hoses and fittings required. This simplifies machine assembly, reduces leak points, and improves reliability in confined and hazardous environments.

5. Hydraulic Power Units (HPUs)

Hydraulic Power Units are central to mining operations, often stationed remotely to power equipment like rock crushers, conveyors, or ventilation systems. Cartridge valves inside HPUs help:

-

Maintain system pressure

-

Divert flow for multiple functions

-

Protect against overheating or overloading

By using Longerfa’s modular cartridge valves, engineers can easily reconfigure HPU setups for different machines or processes without overhauling the entire system.

Why Cartridge Valves Are Ideal for Mining Environments

Mining sites present extreme challenges for any mechanical system: high dust loads, temperature swings, humidity, and continuous operation. In such conditions, traditional inline or stack valves can be difficult to service and prone to contamination.

Cartridge valves offer several advantages:

-

Compact design reduces space requirements and potential leak points.

-

Quick serviceability: Valves can be replaced without dismantling the entire system.

-

Customizable performance via manifold design and pilot control logic.

-

Rugged construction ensures long-lasting performance in aggressive environments.

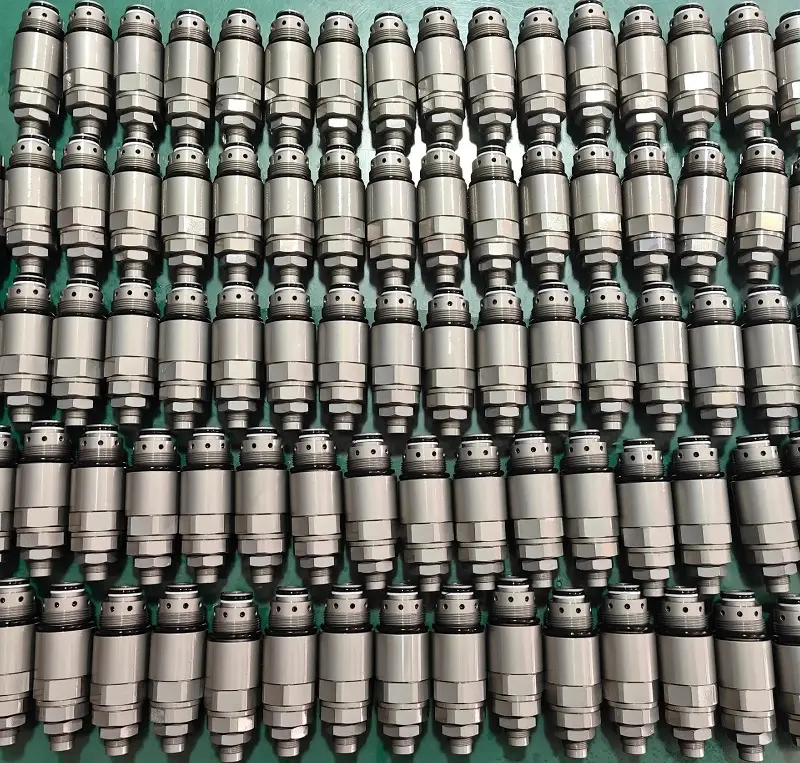

Longerfa’s cartridge valves are made using high-grade steel, precision-machined surfaces, and corrosion-resistant coatings to maximize service life and maintain operational integrity in harsh conditions.

Engineering and Quality at Ningbo Longerfa

At Ningbo Longerfa Hydraulic Co., Ltd., we pride ourselves on delivering not just components, but comprehensive hydraulic control solutions. Our engineering team collaborates closely with OEM manufacturers of mining equipment to:

-

Develop custom valve manifolds

-

Optimize system performance for specific applications

-

Ensure compatibility with international standards (e.g., ISO)

Our product range includes:

-

Main relief valves for excavators and bulldozers

-

Pilot-operated directional control cartridges

-

Modular pressure and flow controls

-

Auxiliary hydraulic kits for mining attachments

All Longerfa products undergo rigorous quality inspection, pressure testing, and life cycle validation before shipment, ensuring reliability under real-world mining conditions.

Innovation and Sustainability

As part of our commitment to innovation and sustainability, Longerfa is actively developing:

-

Energy-efficient valve designs to reduce fuel and power consumption in hydraulic systems

-

Low-leakage cartridge valves to minimize environmental impact and fluid loss

-

Smart valve integration for diagnostics and predictive maintenance in mining 4.0 systems

We believe that the future of mining will be increasingly automated, data-driven, and environmentally conscious—and our hydraulic technologies are evolving to support that future.

Global Reach, Local Support

With clients across Southeast Asia, South America, Africa, and Europe, Longerfa has built a global network of OEM partnerships and service distributors. We offer rapid customization and delivery to mining equipment manufacturers who need:

-

High-quality, OEM-compatible hydraulic valves

-

Localized engineering support

-

On-time logistics and technical aftersales service

Whether you are designing a new fleet of autonomous haulers or retrofitting an existing excavator line, Longerfa has the expertise and solutions to support your hydraulic control needs.

Conclusion

From the control of massive excavators to the fine-tuned operation of drill rigs and underground haulers, hydraulic cartridge valves are central to the safety, efficiency, and productivity of modern mining equipment. At Ningbo Longerfa Hydraulic Co., Ltd., our commitment to precision manufacturing and custom engineering allows us to meet the most demanding requirements of the global mining industry.

We invite you to explore our full range of mining hydraulic solutions or contact our engineering team for custom valve consultation.