Advanced Anti-Backflow Design of DH Check Valves in High-Pressure Hydraulic Systems

Understanding the Role of Check Valves in Hydraulic Systems

Check valves are fundamental components in Hydraulic Circuits. Their primary function is toprevent reverse flow, maintaining system integrity, pressure balance, and safety. In high-pressure applications such as construction excavators, this function becomes more complex due to pressure surges, flow fluctuations, and operational loads.

Doosan Daewoo DH-series excavators feature intricate hydraulic return systems that require precise oil flow regulation. Here, the oil return distribution check valve serves a dual purpose:

-

Allows controlled return flow of hydraulic fluid to the tank or reservoir.

-

Prevents sudden backflow, which could damage pumps, actuators, or result in inefficient operation.

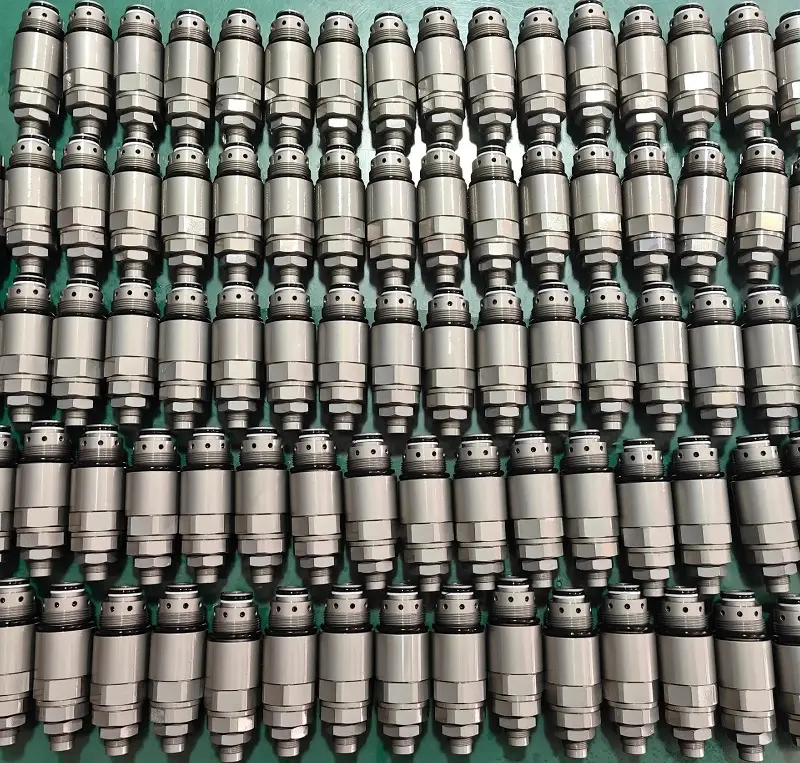

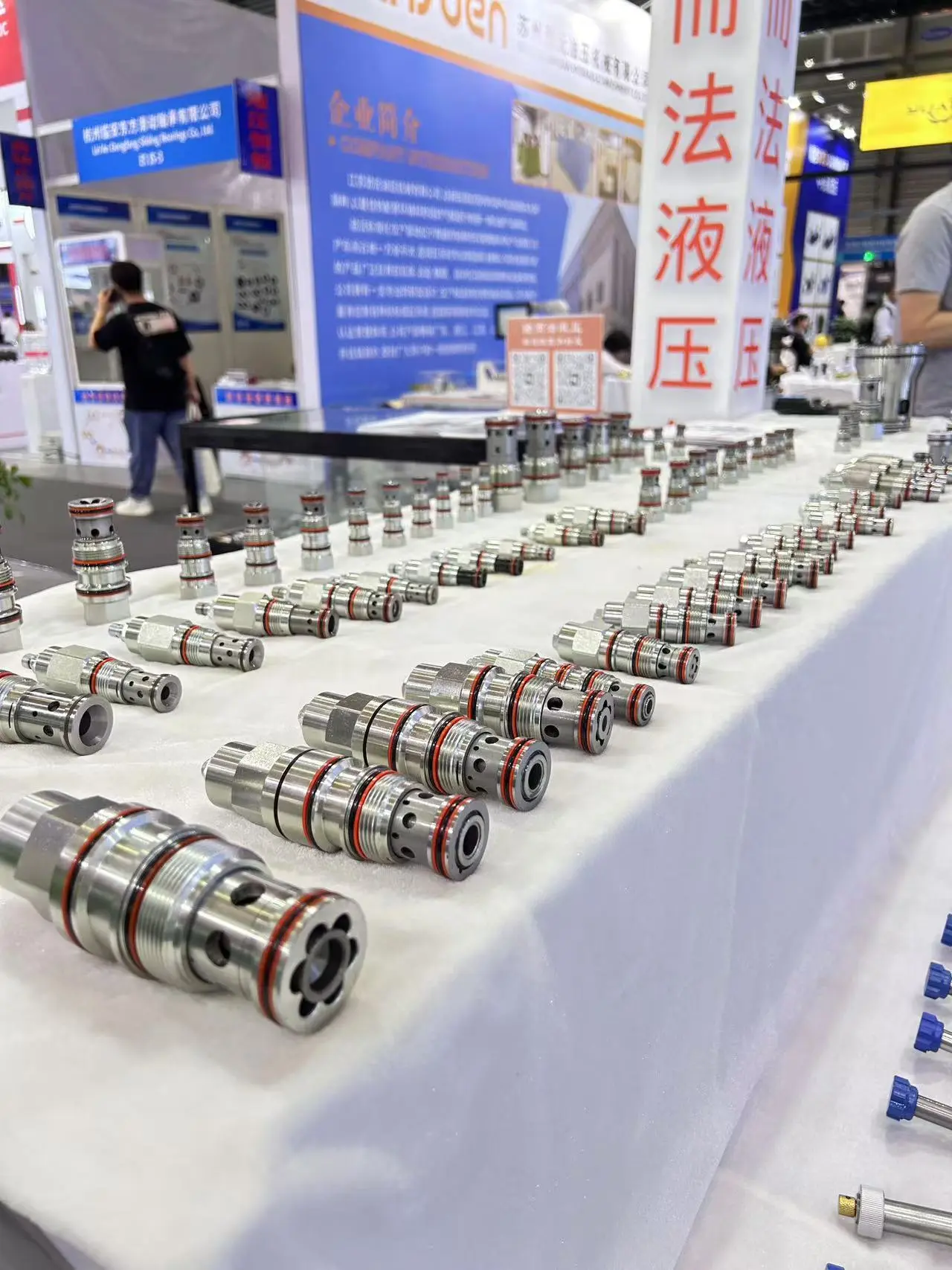

DH Check Valves: Designed for Durability and Reliability

Ningbo Longerfa's DH check valves are engineered with a deep understanding of Hydraulic Pressure behavior in real-world applications. For Doosan Daewoo excavators such as theDH200, DH215, DH220, and DH225-7, our check valves ensure long service life, minimal maintenance, and seamless compatibility.

Core Specifications:

-

Model: Oil Return Distribution Check Valve

-

Applicable Machines: Doosan Daewoo DH200, DH215, DH220, DH225-7

-

Material: High-strength alloy steel with anti-corrosive treatment

-

Working Pressure: Up to 35 MPa (350 bar)

-

Temperature Range: -30°C to +110°C

-

Seal Type: NBR/Viton (customizable)

-

Mounting: Cartridge-type or manifold-type based on configuration

Anti-Backflow Design: Technical Analysis

The anti-backflow capability of our DH check valve stems from a multi-stage sealing and flow-guided valve core structure. Below is a detailed breakdown of its operational efficiency:

1. Precision Valve Seat Geometry

The valve seat is hardened and precision-ground to ensure tight contact with the valve core under reverse pressure. This prevents micro-leakages that typically occur in high-cycle operations.

2. Flow-Guided Valve Core

The valve core features grooved guide rails that direct the flow smoothly and reduce turbulence. This eliminates pressure spikes during transition states and supports stable backflow resistance under high pressure.

3. Dual Sealing Technology

In addition to mechanical sealing, the check valve integrates a secondary elastomeric seal that activates under pressure. This redundancy is critical for machines like the DH225-7, where pressure fluctuations can exceed 30 MPa.

4. Low Opening Pressure

Designed for low cracking pressure, the valve allows easy opening under minimal forward flow pressure, ensuring energy efficiency without compromising on anti-backflow integrity.

5. Shock Resistance

Thanks to an internal damping structure, the valve resists hydraulic shock during sudden load changes or pump starts, which commonly occur during boom or arm operation on DH excavators.

Application in Doosan Daewoo DH Excavators

Let’s explore how this design supports operational efficiency and system safety in the following Doosan models:

🛠️ DH200 / DH215

These mid-sized excavators rely on responsive control for tasks like trenching and material handling. The check valve ensures:

-

Consistent return flow during varied joystick movements.

-

No fluid kickback into the main pump under load reversal.

🛠️ DH220

The popular DH220 model is known for handling moderate to heavy-duty applications. In this context, our valve prevents:

-

Cylinder retraction lag due to reverse pressure buildup.

-

Seal blowouts in hydraulic actuators caused by backpressure.

🛠️ DH225-7

The -7 series is equipped with higher working pressures and advanced electronic control. Our anti-backflow check valve:

-

Improves actuator feedback accuracy by stabilizing fluid direction.

-

Enhances system lifespan by mitigating internal wear from uncontrolled backflows.

Why Choose Ningbo Longerfa DH Check Valves?

At Ningbo Longerfa, quality is our priority. Here’s why our DH check valves stand out:

-

OEM-Level Compatibility: Direct fit for Doosan Daewoo DH200, DH215, DH220, and DH225-7.

-

100% Bench-Tested: Each valve is tested for leakage, pressure holding, and flow rate.

-

Customizable Designs: We support modifications for different flow rates, pressures, or mounting specs.

Customer Feedback: Real-World Validation

“We’ve replaced several OEM check valves with Longerfa DH valves. The machines run smoother, especially during simultaneous arm and boom movement. No leaks so far after 900 hours.”

— Mr. Zhao, Excavator Fleet Manager, Inner Mongolia

“The anti-backflow performance is clearly superior. We’ve had fewer valve-related failures since switching to Longerfa valves on our DH225-7 excavators.”

— Mr. Rajan, Hydraulic Technician, UAE