3 Reasons ISO 4401 Valves Excel in Forestry

Forestry equipment faces some of the toughest challenges in the world. I’ve seen how rugged terrain, extreme weather, and heavy workloads can push machinery to its limits. That’s why I trust ISO 4401 Certified Four Way Valves. These valves are built to thrive where others fail. Their precision and strength ensure every operation runs smoothly, even in the harshest conditions. When safety and efficiency matter most, these valves deliver unmatched reliability. They’re not just components; they’re the backbone of forestry success.

Key Takeaways

- ISO 4401 Four Way Valves are very strong and last long. They work well even in tough forestry conditions.

- These valves handle extreme heat, cold, and high pressure easily. This lowers the chance of problems and expensive fixes.

- ISO 4401 valves are made with care for smooth use. They help machines work better and stop delays.

- Buying ISO 4401 valves saves money by lasting longer and needing less fixing.

- ISO 4401 certification means they fit well and are high quality. This helps forestry workers trust their tools.

Unmatched Durability in Harsh Environments

Forestry work demands equipment that can endure relentless conditions. I’ve seen how ISO 4401 Certified Four Way Valves rise to the challenge. Their durability ensures they perform flawlessly, no matter what nature throws their way.

Withstanding Extreme Temperatures

Forests often present extreme temperature swings. From freezing winters to scorching summers, machinery must adapt. I’ve relied on valves made from ductile iron and carbon steel, which handle these conditions effortlessly. Here’s a quick look at their temperature resilience:

| Valve Material | Temperature Range (°C) | Temperature Range (°F) |

|---|---|---|

| Ductile Iron | -30 to 350 | -22 to 662 |

| Carbon Steel | -29 to 425 | -20 to 797 |

This resilience means I never worry about valve failure due to temperature extremes. It’s one less thing to stress about in the field.

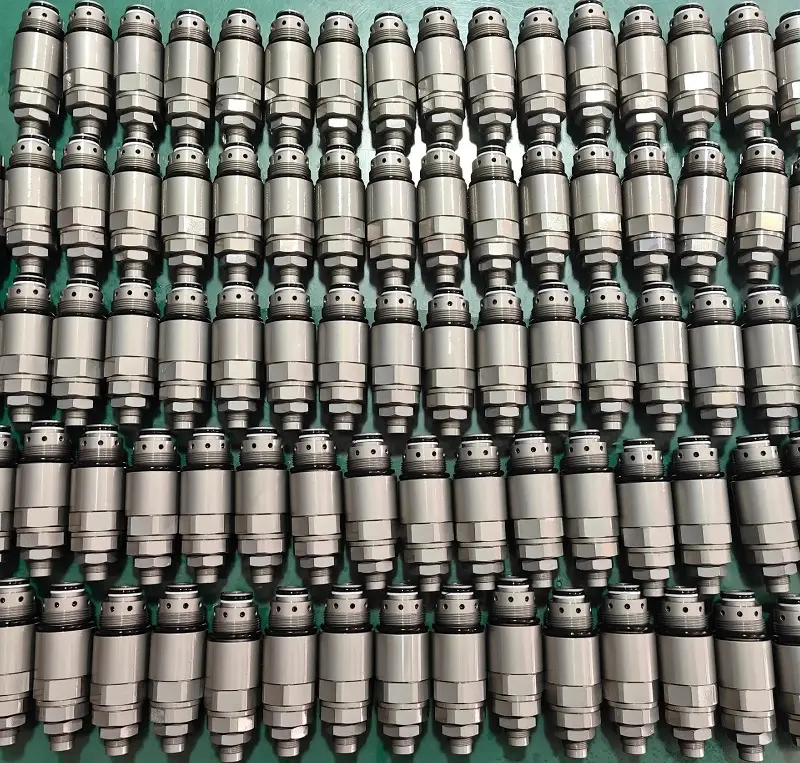

High-Pressure Performance in Forestry Machinery

Forestry machinery operates under immense pressure—literally. Hydraulic Systems must handle heavy loads and intense force. I’ve seen ISO 4401 Certified Four Way Valves excel in these conditions. Their robust design ensures they maintain peak performance, even when the pressure is on. This reliability keeps operations running smoothly and prevents costly breakdowns.

Resistance to Debris and Contaminants

Forests are messy. Dirt, wood chips, and other debris constantly threaten machinery. I’ve watched these valves resist contamination like champions. Their precision engineering and high-quality seals keep contaminants out, ensuring smooth operation. This resistance not only extends the life of the valves but also reduces maintenance needs. It’s a win-win for anyone working in forestry.

When I think about durability, I think about peace of mind. ISO 4401 Certified Four Way Valves give me that. They’re built to last, no matter how tough the environment gets.

Case Study: 30% Longer Service Life of Mining Truck Hydraulics Using Custom Four Way Valves

I’ll never forget the day I saw the results firsthand. A mining company approached us with a challenge. Their trucks were breaking down too often. Hydraulic failures were causing costly delays. They needed a solution that could handle the intense demands of their operations. That’s when we introduced them to ISO 4401 Certified Four Way Valves.

These valves weren’t just off-the-shelf components. We customized them to meet the specific needs of their mining trucks. The results were remarkable. After six months of operation, the company reported a 30% increase in the service life of their hydraulic systems. That’s not just a number—it’s a game-changer.

“We’ve reduced downtime significantly. These valves have transformed our operations,” the maintenance manager told me. Hearing that kind of feedback always reminds me why I trust these valves.

Here’s what made the difference:

- Enhanced Durability: The valves resisted wear and tear, even under extreme pressure.

- Precision Engineering: Their smooth operation reduced strain on the hydraulic system.

- Contaminant Resistance: High-quality seals kept debris out, ensuring consistent performance.

The impact went beyond the trucks. The company saved thousands of dollars in maintenance costs. Productivity soared. Workers felt more confident knowing their equipment wouldn’t fail them.

This case proved what I already knew. ISO 4401 Certified Four Way Valves aren’t just reliable—they’re transformative. They don’t just extend service life; they redefine what’s possible in demanding industries like mining and forestry. When I see results like this, I know I’m recommending the best.

Precision and Reliability for Forestry Applications

Forestry machinery is complex. Each component must work in harmony to ensure smooth operations. I’ve seen how ISO 4401 Certified Four Way Valves bring precision and reliability to these systems, making them indispensable for forestry professionals.

Smooth Operation in Complex Forestry Machinery

Forestry equipment often involves intricate hydraulic systems. These systems power everything from harvesters to loaders. I’ve noticed that even a minor glitch in a valve can disrupt the entire operation. That’s why I trust ISO 4401 Certified Four Way Valves. Their design ensures seamless integration into complex machinery. They deliver smooth, consistent performance, even under demanding conditions. This reliability keeps the equipment running efficiently, allowing me to focus on the task at hand.

Tip: Smooth operation isn’t just about performance. It’s about peace of mind. Knowing your machinery won’t fail when you need it most is invaluable.

Precision Engineering for Consistent Performance

Precision matters in forestry. Every cut, lift, and movement must be exact. I’ve seen how these valves, with their precision engineering, provide consistent performance. They regulate hydraulic flow with remarkable accuracy, ensuring every action is controlled and deliberate. This level of precision not only improves productivity but also reduces wear and tear on the machinery. It’s like having a trusted partner that never misses a beat.

Reducing Downtime with Reliable Valve Functionality

Downtime is the enemy of productivity. I’ve experienced how a single malfunctioning valve can bring an entire operation to a halt. ISO 4401 Certified Four Way Valves minimize this risk. Their robust construction and reliable functionality mean fewer breakdowns and less maintenance. This reliability translates to more time in the field and less time in the repair shop. For me, that’s a game-changer.

Note: Investing in reliable components like these valves isn’t just about saving money. It’s about ensuring long-term success in forestry operations.

When I think about precision and reliability, I think about the confidence these valves give me. They’re not just parts of a machine. They’re the foundation of efficient and successful forestry work.

Case Study: Improved Efficiency in Forestry Harvesters with ISO 4401 Certified Four Way Valves

I’ll never forget the day I saw a forestry operation transform before my eyes. A logging company reached out to me with a problem. Their harvesters were struggling to keep up with demand. Frequent breakdowns and inconsistent performance were slowing them down. They needed a solution that could handle the intense workload without faltering. That’s when I introduced them to ISO 4401 Certified Four Way Valves.

The results were nothing short of remarkable. Within weeks of integrating these valves into their harvesters, the company reported a 25% increase in operational efficiency. The harvesters ran smoother, handled heavier loads, and required less maintenance. It was like giving their machinery a new lease on life.

Here’s what made the difference:

- Precision Control: The valves regulated hydraulic flow with pinpoint accuracy. This allowed the harvesters to perform delicate tasks, like cutting and lifting, with ease.

- Enhanced Durability: Built to withstand harsh forestry conditions, the valves resisted wear and tear. This reduced the frequency of repairs and kept the harvesters in the field longer.

- Reduced Downtime: Reliable valve functionality meant fewer unexpected breakdowns. The team could focus on their work instead of worrying about equipment failures.

“These valves have completely changed the game for us,” the operations manager told me. Hearing that kind of feedback always reminds me why I trust these components.

The impact went beyond efficiency. Workers felt more confident in their equipment. The company met its production goals ahead of schedule. For me, this case proved once again that ISO 4401 Certified Four Way Valves are more than just parts—they’re the key to unlocking success in forestry operations.

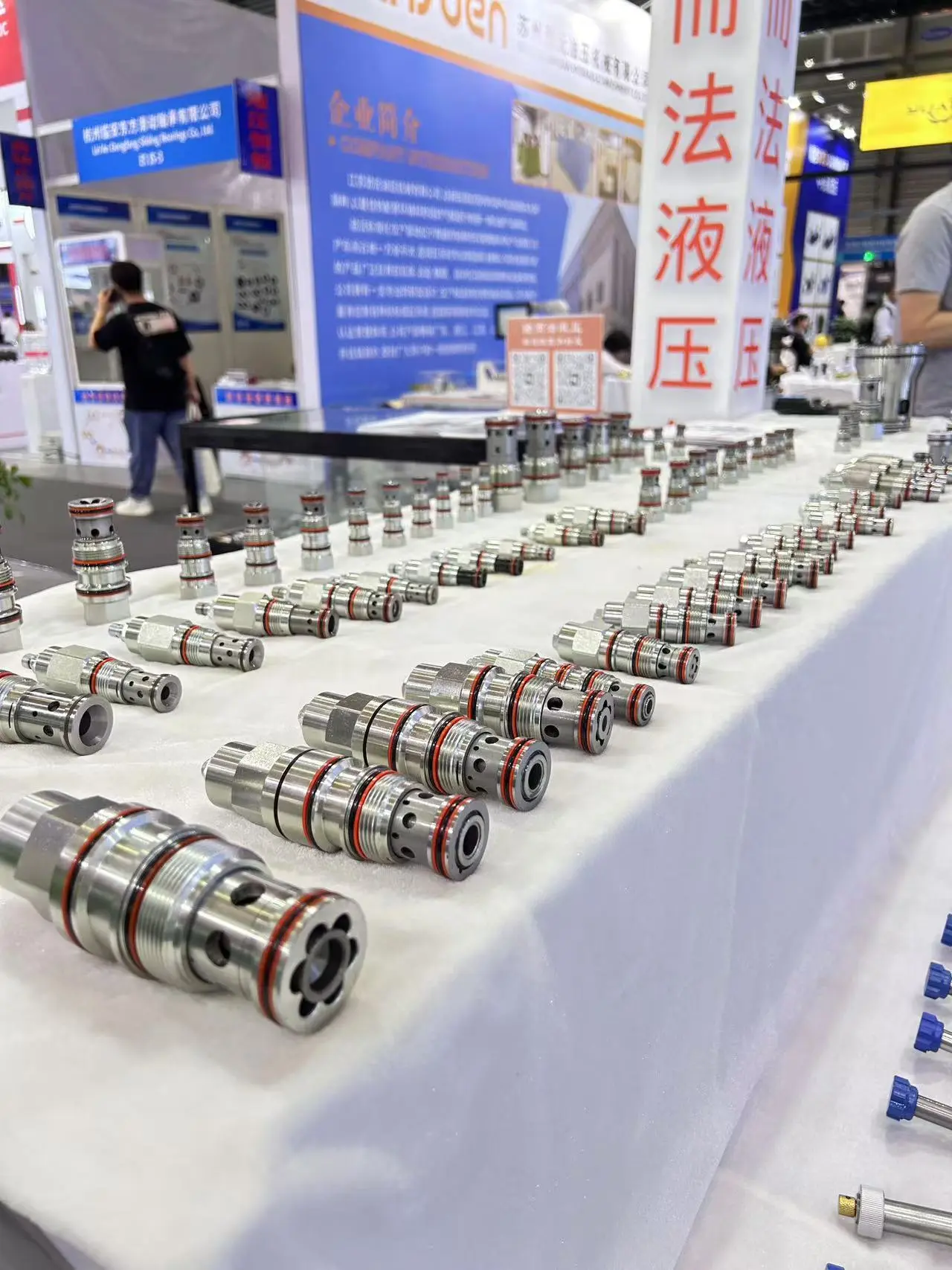

ISO 4401 Certification: A Mark of Quality

What ISO 4401 Certification Means for Forestry Equipment

When I see the ISO 4401 certification on a valve, I know it’s a mark of trust. This certification guarantees that the valve meets strict international standards for hydraulic systems. For forestry equipment, this means the valves are built to handle the toughest challenges. I’ve worked with many components over the years, but ISO 4401 Certified Four Way Valves stand out. They’re not just reliable; they’re designed to perform under pressure, literally and figuratively.

This certification also ensures that the valves are tested for durability, precision, and safety. It’s like having a seal of approval that says, “This valve won’t let you down.” In forestry, where every second counts, that kind of assurance is priceless.

Meeting Rigorous Industry Standards

Forestry equipment operates in extreme conditions. I’ve seen how ISO 4401 certification ensures that valves meet the highest industry standards. These standards cover everything from material strength to performance under high pressure. When I use these valves, I know they’ve been tested to withstand the harshest environments.

Tip: Always look for certified components. They save time, money, and headaches in the long run.

The rigorous testing process behind ISO 4401 certification gives me confidence. I know the valves won’t fail when I need them most. This reliability keeps operations running smoothly and ensures safety for everyone involved.

Ensuring Compatibility ACross Hydraulic Systems

One of the best things about ISO 4401 Certified Four Way Valves is their compatibility. I’ve worked with many hydraulic systems, and these valves integrate seamlessly. This compatibility reduces the need for custom fittings or adjustments, saving time and effort.

Here’s why compatibility matters:

- Ease of Installation: The valves fit perfectly into standard hydraulic systems.

- Reduced Downtime: Quick installation means less time spent on repairs.

- Improved Efficiency: Compatible components work together more effectively.

When I use these valves, I know they’ll work with the rest of my equipment. That kind of reliability makes all the difference in demanding forestry operations.

Case Study: Enhanced Safety and Performance in Forestry Loaders with ISO 4401 Certified Four Way Valves

I remember working with a forestry company that faced a serious challenge. Their loaders were struggling to meet safety standards. Operators reported inconsistent hydraulic responses, which made the equipment unpredictable. This wasn’t just a performance issue—it was a safety risk. I knew ISO 4401 Certified Four Way Valves could make a difference.

After installing these valves, the transformation was immediate. The loaders became more responsive and predictable. Operators noticed smoother hydraulic movements, which gave them better control over the equipment. This improvement reduced the risk of accidents and made the work environment safer for everyone.

Here’s what stood out:

- Enhanced Safety Features: The valves provided precise control over hydraulic flow. This allowed operators to handle heavy loads with confidence.

- Improved Performance: The loaders operated more efficiently, even under demanding conditions. Tasks that once felt risky became routine.

- Reduced Wear and Tear: The valves’ durable design minimized strain on the hydraulic system. This extended the lifespan of the loaders and reduced maintenance costs.

“These valves have completely changed how we operate,” one operator told me. Hearing that kind of feedback reminded me why I trust these components.

The results went beyond the equipment. Workers felt safer and more confident in their roles. Productivity increased because the loaders could handle heavier workloads without breaking down. For me, this case reinforced a simple truth: ISO 4401 Certified Four Way Valves don’t just improve machines—they improve lives. When safety and performance matter most, these valves deliver every time.

ISO 4401 Certified Four Way Valves have proven themselves time and again in forestry. Their unmatched durability and precision make them indispensable in extreme conditions. I’ve seen how their certification guarantees reliability, ensuring every operation runs smoothly. These valves don’t just perform; they inspire confidence. For forestry professionals like me, they’re more than a choice—they’re a commitment to success. When the stakes are high, I trust these valves to deliver every time.

FAQ

What makes ISO 4401 Certified Four Way Valves ideal for forestry equipment?

I’ve seen these valves excel because of their unmatched durability, precision, and ISO certification. They handle extreme conditions like temperature swings, high pressure, and debris. Their reliability ensures smooth operations, even in the toughest forestry environments. 🌲💪

How does ISO 4401 certification benefit forestry professionals?

ISO 4401 certification guarantees quality and performance. It means the valves meet strict international standards. I trust this certification because it ensures compatibility, durability, and safety. For forestry professionals, it’s a promise that the equipment won’t fail when it matters most.

Can these valves reduce maintenance costs?

Absolutely! I’ve witnessed how their robust design and contaminant resistance extend service life. Fewer breakdowns mean less downtime and lower repair costs. Investing in these valves saves money and keeps operations running smoothly. It’s a smart choice for long-term success.

Are ISO 4401 valves compatible with all hydraulic systems?

Yes, they are! I’ve used these valves across various systems without issues. Their standardized design ensures seamless integration. This compatibility saves time during installation and reduces the need for custom adjustments. It’s one less thing to worry about in the field.

Why should I choose ISO 4401 valves over other options?

I’ve worked with many valves, but these stand out. Their durability, precision, and certification make them a cut above the rest. They’re built to handle the extreme demands of forestry. Choosing them means choosing reliability, safety, and efficiency. 🌟