Advancing Vertical Logistics: Ningbo Longerfa Unveils Next-Generation Hydraulic Control Valve Groups for Lifting Cargo Elevators

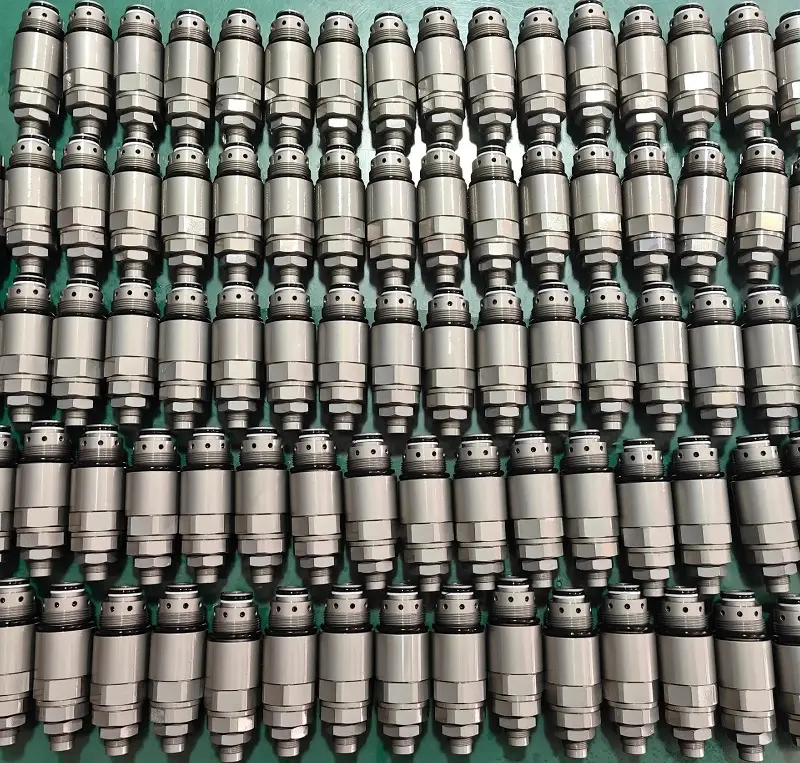

In today’s fast-paced industrial landscape, efficiency, reliability, and safety have become non-negotiable expectations in vertical logistics solutions. As global demand for cargo elevators and vertical lifting systems continues to grow—driven by booming e-commerce, warehousing, and manufacturing sectors—Ningbo Longerfa Hydraulic Co., Ltd. is proud to announce the launch of its next-generation Hydraulic Control Valve Groups specially engineered for lifting cargo elevators.

These new valve assemblies, developed through years of in-house R&D and rigorous testing, aim to set a new benchmark in the performance, safety, and energy efficiency of hydraulic lifting systems.

Pressure Regulation in Excavators: The Role of Hydraulic Relief Valves

In the ever-evolving world of construction machinery, the demand for efficiency, reliability, and safety has never been higher. At the core of these demands lies the critical role of Hydraulic Systems in excavators. Among the essential components of these systems, hydraulic relief valvesstand out as unsung heroes, ensuring optimal performance and protecting vital machinery components. This article explores how pressure regulation is achieved in excavators, and why hydraulic Relief Valves are indispensable for modern hydraulic systems.

Hydraulic Valve Failures in Construction Machinery: Causes and Prevention

How Quality and Expertise from Ningbo Zhenhai Can Make a Difference

In today’s fast-paced construction industry, hydraulic systems are the heart of heavy machinery. Whether it's an excavator, loader, bulldozer, or crane, the seamless operation of hydraulic components is essential to ensure high efficiency, low downtime, and safe working conditions. Among these components, hydraulic valves—particularly relief valves—play a critical role in maintaining system pressure and protecting equipment from overloading.

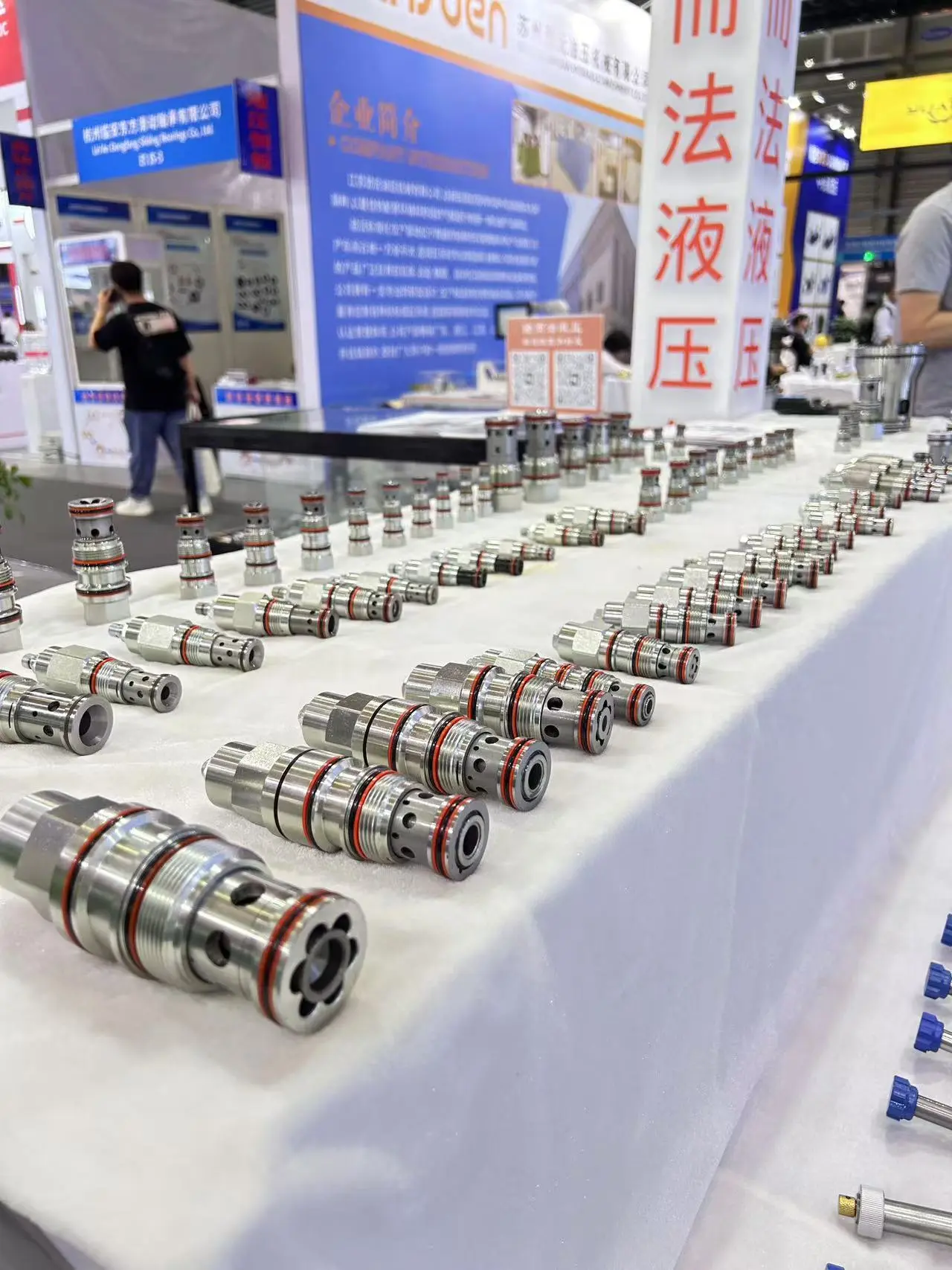

However, hydraulic valve failures remain one of the most common and costly issues in construction equipment maintenance. At Longerfa Hydraulic, a leading cartridge valve and relief valve manufacturer based in Zhenhai, Ningbo, we’ve spent over a decade studying valve failure causes and perfecting our products to minimize these risks. With a strong international export footprint, we aim to support equipment manufacturers and maintenance teams worldwide with reliable, high-performance valve solutions.

The Role of Pressure Relief Valves in Construction Machinery: Enhancing Safety, Stability, and Hydraulic Efficiency

In the world of construction machinery, where precision, safety, and durability are paramount, pressure relief valves play a critical role in ensuring the optimal performance and protection of hydraulic systems. At Ningbo Longerfa, we specialize in the development and production of high-quality main and secondary relief valves for excavators, serving customers across global markets with reliable, efficient solutions.

How Hydraulic Cartridge Valves Enhance Performance in Agricultural Machinery

In the ever-evolving world of agriculture, machinery plays a pivotal role in increasing productivity, ensuring efficiency, and reducing labor-intensive tasks. As agricultural operations become more sophisticated and mechanized, the demand for high-performance, reliable, and energy-efficient hydraulic systems has never been greater. Among the many components that contribute to the smooth functioning of modern agricultural machinery, hydraulic cartridge valves stand out as a vital element in enhancing performance, durability, and control.

At Ningbo Longerfa Hydraulic Co., Ltd., we specialize in the design, manufacturing, and supply of high-quality hydraulic components, including a full range of hydraulic cartridge valves engineered to meet the rigorous demands of agricultural machinery. In this article, we explore how these valves contribute to the success of agricultural equipment and why they are a preferred choice for OEMs and maintenance engineers across the industry.

Applications of Hydraulic Cartridge Valves in Mining Equipment

As global demand for mineral resources continues to grow, the mining industry is increasingly reliant on high-performance, efficient, and durable machinery to meet production targets and safety standards. At the heart of these machines lies a critical component that governs performance, precision, and power: hydraulic cartridge valves.

Hydraulic cartridge valves, often hidden from view within valve blocks or manifolds, play a pivotal role in managing the flow and pressure of hydraulic fluid within mining equipment. As a leading manufacturer of engineering machinery hydraulic components, Ningbo Longerfa Hydraulic Co., Ltd. is at the forefront of designing and delivering high-quality cartridge valves tailored to meet the harsh demands of the mining sector.

In this article, we explore the wide-ranging applications of hydraulic cartridge valves in mining equipment, and how innovations by Longerfa are contributing to safer, more efficient, and more reliable mining operations worldwide.

How Hydraulic Cartridge Valves Improve System Efficiency in Heavy Machinery

In the world of heavy machinery, efficiency is paramount. From excavators to cranes, every piece of equipment is designed to operate at peak performance to maximize productivity, minimize downtime, and reduce operating costs. One of the most significant innovations in hydraulic systems that has contributed to improving overall machinery performance is the hydraulic cartridge valve.

The Role of Hydraulic Cartridge Valves in Modern Industrial Applications

Hydraulic cartridge valves are an essential component in modern industrial systems, known for their ability to provide precise control over hydraulic fluid flow. These valves play a crucial role in a wide range of applications, from construction machinery to agricultural equipment, offering significant benefits in terms of efficiency, safety, and reliability. In this article, we explore the key features of hydraulic cartridge valves, their role in modern industrial applications, and how they contribute to system performance.

Advanced Anti-Backflow Design of DH Check Valves in High-Pressure Hydraulic Systems

A Technical Insight from Ningbo Longerfa for Doosan Daewoo DH Check Valves

Ningbo Longerfa Hydraulic Cartridge Valve Manufacturer | Published: May 15, 2025

As the demand for robust hydraulic control systems increases in the heavy machinery sector, the importance of reliable anti-backflow mechanisms becomes critical. At Ningbo Longerfa Hydraulic Cartridge Valve Manufacturer, we’re committed to delivering high-performance solutions tailored for demanding applications. Today, we take a closer look at our DH check valves—especially designed for high-pressure hydraulic systems—and their innovative anti-backflow design. This technical analysis is particularly relevant to the oil return distribution systems of Doosan Daewoo DH200, DH215, DH220, and DH225-7 excavators.

Caterpillar Original Factory Valves vs. Domestic High-Compatibility Valves: A Comprehensive Cost and Performance Comparison

In the world of construction machinery, the reliability and performance of hydraulic valves are paramount. The right valve can ensure optimal machinery performance, reduce downtime, and enhance overall productivity. Among the numerous options available, two types of valves dominate the market: original factory valves, such as those made by Caterpillar (CAT), and high-compatibility domestic valves that promise to provide an alternative at a lower cost.

This article explores the differences in cost and performance between Caterpillar original factory valves and domestic high-compatibility valves, focusing specifically on products like the 1057459 Main Relief Valve (CAT312), the 310-0395 Relief Valve (CAT320C), and the 6E-2273 Relief Valve (CAT320C). By analyzing the advantages and disadvantages of each type, we aim to provide insight into which choice may be the most cost-effective and reliable for construction machinery users.