Top Manufacturers of High-Quality Needle Valves for Optimal Flow Direction Performance

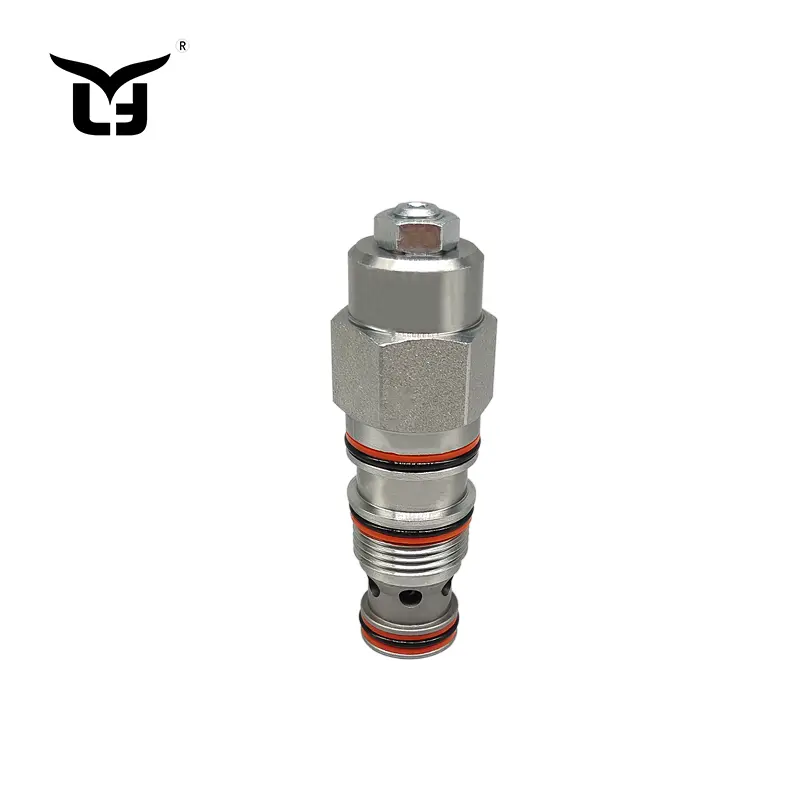

Needle valves play a crucial role in precision flow control, enabling the regulation of liquid and gas flow across a variety of applications. At Ningbo Longerfa Hydraulic Co., Ltd., our focus is on producing high-quality needle valves that adhere to rigorous industry standards. With a finely tuned needle design, our valves facilitate precise adjustments while minimizing flow turbulence, which is vital for maintaining system efficiency. Crafted from robust materials, these valves offer exceptional wear and corrosion resistance, ensuring reliable performance even in challenging environments. Clearly marked flow directions make integration into existing systems straightforward, providing users with optimal functionality. Suitable for industries such as oil and gas, chemical processing, and any application requiring meticulous fluid control, our needle valves represent a trusted choice for reliability and accuracy. Rely on Ningbo Longerfa Hydraulic Co., Ltd. for innovative solutions that enhance operational efficiency and uphold the highest quality standards in fluid management.Insider Tips For Needle Valve Flow Direction Manufacturers Dominates Service

When it comes to sourcing high-quality needle valves, understanding the flow direction is crucial for manufacturers. As a trusted player in the hydraulic components industry, Ningbo Longerfa Hydraulic Co., Ltd. emphasizes the importance of optimizing your selection process by considering key insights that can streamline operations and enhance product performance. Our expertise in the research and development of Hydraulic Valve sets and components positions us to share insider tips that can benefit global buyers. Firstly, ensure you are aware of the specific applications for which you are procuring needle valves—this knowledge guides you in making informed choices concerning materials, size, and pressure ratings. Secondly, engaging with manufacturers who prioritize high-tech innovations can significantly improve the versatility and reliability of the products you acquire. At Longerfa, we leverage advanced technologies to ensure our products not only meet but exceed industry standards. Finally, building a collaborative relationship with manufacturers allows for better customization options and ongoing technical support. At Ningbo Longerfa, we pride ourselves on being a national high-tech enterprise dedicated to meeting the evolving needs of our clients. By following these insider tips, global purchasers can enhance their sourcing strategy, ensuring efficient and reliable hydraulic solutions that drive business success.

Insider Tips For Needle Valve Flow Direction Manufacturers Dominates Service

| Tip Category | Description | Importance Level | Implementation Timeline |

|---|---|---|---|

| Flow Testing | Conduct flow testing under various conditions to ensure valve reliability. | High | Ongoing |

| Documentation | Maintain comprehensive documentation for installation and maintenance procedures. | Medium | 1 Month |

| Staff Training | Regularly train staff on new technologies and safety procedures. | High | Quarterly |

| Quality Control | Implement rigorous quality control measures at every production phase. | High | Ongoing |

| Customer Feedback | Actively seek and incorporate customer feedback for product improvement. | Medium | Ongoing |

7 Key Tips To Needle Valve Flow Direction Manufacturers Manufacturer Factory-Direct Excellence

A

Andrew Nelson

Superb quality! The follow-up service was remarkably good, demonstrating a commitment to customer care.

04 June 2025

J

Julia Hall

Incredible purchase! Product quality is fantastic, with an equally impressive support team.

13 May 2025

B

Benjamin White

The product quality is simply exceptional! The follow-up support was remarkably professional.

31 May 2025

E

Ella Harris

Wonderful product! The support staff demonstrated true professionalism and were very helpful.

09 June 2025

W

Wyatt Edwards

The product quality is superb! Their after-sales service was prompt and professional.

18 June 2025

S

Sienna Black

Amazing product! I was impressed not only with the quality but also with their customer service.

06 June 2025