Valve Manufacturing Process: Essential Insights from China's Leading Factories

At Ningbo Longerfa Hydraulic Co., Ltd., we excel in the precision manufacturing of high-quality valves designed for a variety of industrial applications. Our advanced manufacturing facility leverages cutting-edge technology and strict quality control measures to ensure that every valve we produce meets the highest industry standards. The process starts with the careful selection of premium materials and continues through precision machining and expert assembly techniques. Each valve is rigorously tested, including pressure and flow evaluations, to ensure optimal performance and durability. With a commitment to innovation and excellence, our valves are engineered to withstand diverse operating conditions, catering to industries such as oil and gas, water supply, and manufacturing. Choosing our valves means investing in reliability and efficiency, backed by our extensive experience and dedication to customer service. Partnering with us guarantees exceptional quality and tailored solutions to meet your specific requirements.Best Methods To Manufacturing Process Of Valves Manufacturer Outperforms the Competition From Concept to Delivery

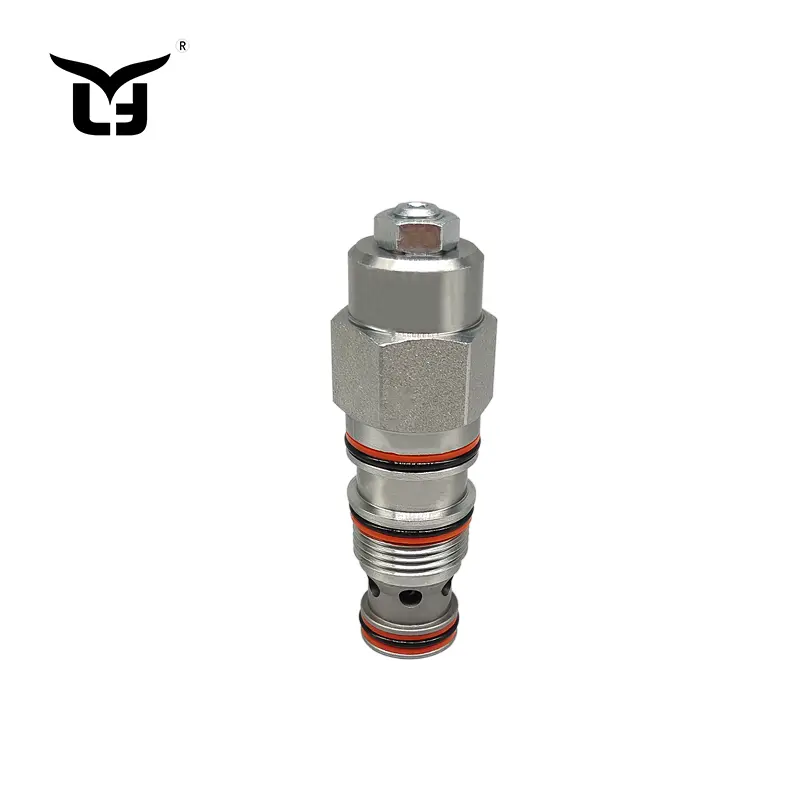

At Ningbo Longerfa Hydraulic Co., Ltd., we pride ourselves on being at the forefront of Hydraulic Valve manufacturing, seamlessly integrating innovation with efficiency. As a national high-tech enterprise, we understand the importance of not just meeting industry standards but exceeding them. Our approach to the manufacturing process of hydraulic products, including valve sets, thread plug valves, and valve blocks, is designed to outperform competitors from concept to delivery. From the initial design phase, our dedicated R&D team employs cutting-edge technology and a customer-centric mindset to develop products that align with the evolving needs of global buyers. Each product undergoes rigorous testing to ensure durability and performance in the most challenging environments. Our streamlined manufacturing processes leverage automation and skilled craftsmanship, ensuring that each hydraulic component meets strict quality standards without compromising on speed. Moreover, our commitment to efficiency extends to our supply chain management and logistics. By optimizing our processes and maintaining strategic partnerships, we ensure timely delivery to clients worldwide. Choosing Ningbo Longerfa means not only acquiring high-quality hydraulic solutions but also collaborating with a partner who prioritizes innovation and reliability at every stage. Join us in redefining industry standards and experience the difference in sourcing hydraulic products that truly stand out.

Best Methods To Manufacturing Process Of Valves Manufacturer Outperforms the Competition From Concept to Delivery

| Method | Description | Advantages | Lead Time (Days) | Cost Efficiency |

|---|---|---|---|---|

| 3D Printing | Additive manufacturing technique allowing complex valve designs. | Reduced material waste, faster prototyping. | 5-15 | High efficiency for low-volume production. |

| CNC Machining | Computer-controlled manufacturing process for precise valve machining. | High precision, repeatability in production. | 10-20 | Cost-effective for medium to large production runs. |

| Casting | A process where liquid material is poured into a mold. | Versatile for various materials, shapes. | 15-30 | Low cost for mass production. |

| Forging | Shaping materials by applying compressive forces. | Enhanced strength and durability. | 20-40 | Economical for high-strength applications. |

| Welding | Joining materials using high heat to melt parts. | Creates robust and seamless joints. | 10-25 | Cost-effective for complex assemblies. |

Finding Your Perfect Match Manufacturing Process Of Valves Manufacturer Guarantees Peak Performance Is The Best

M

Michelle Clark

Fantastic item! The after-sales service was helpful, and the representatives were very knowledgeable.

09 June 2025

S

Sophia Garcia

Wonderful product! Their after-sales service was clear and extremely professional.

08 June 2025

G

Greg Stewart

Fantastic quality! Their support staff were amazing—truly knowledgeable and ready to assist.

03 July 2025

D

David Jones

I’m extremely pleased! The quality is excellent, and the customer service has been fantastic.

04 July 2025

J

Jack Lee

What a great purchase! The product quality is impressive, and the support team was very accommodating.

05 June 2025

G

Gabriel White

Quality exceeded expectations! Their support team was knowledgeable and supportive.

30 May 2025