China Valve Manufacturing: In-Depth Look at Leading Factories & Top Manufacturers

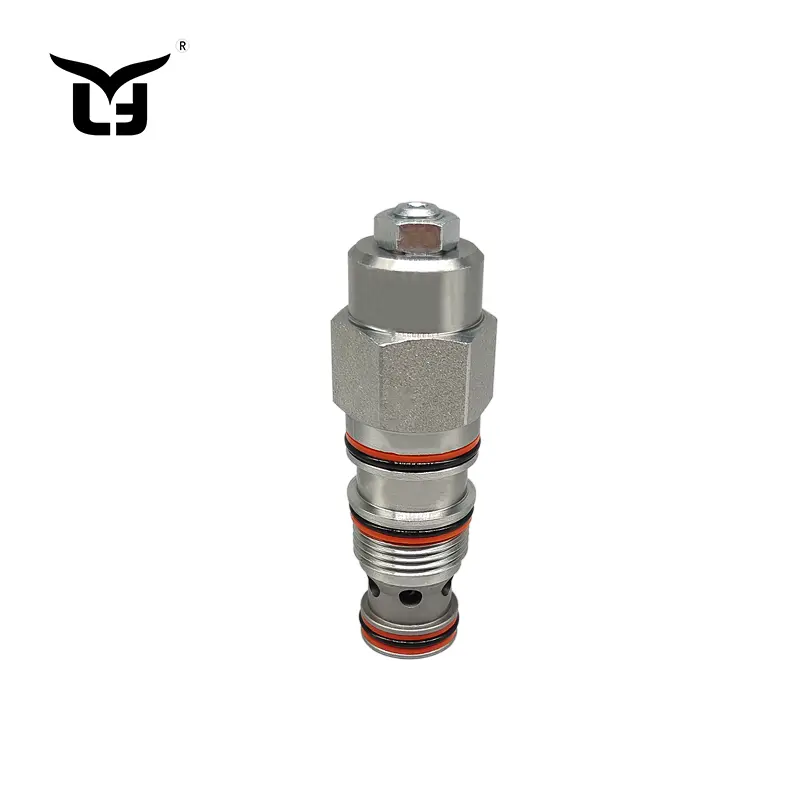

Ningbo Longerfa Hydraulic Co., Ltd. is dedicated to manufacturing top-tier valves, utilizing advanced technology and extensive expertise in hydraulic systems. Our meticulous manufacturing process adheres to strict standards, ensuring every valve is engineered for precision and durability. From design and material selection to machining and assembly, we employ skilled professionals at every stage. Our state-of-the-art equipment and rigorous quality control measures ensure that all our products comply with international specifications. We offer a wide variety of valves suited for numerous industries, including oil and gas, water management, and construction. At Ningbo Longerfa, innovation is at the core of our processes, allowing us to provide tailored solutions that address our clients' specific requirements. With an unwavering commitment to excellence and customer satisfaction, we deliver reliable and efficient valve solutions that enhance operational performance.China’s Best-Selling Manufacturing Process Of Valves Factory Application More Than a Supplier - A Partner

In the rapidly evolving landscape of industrial manufacturing, finding a reliable partner who understands the complexities of hydraulic systems can be a game-changer for global procurement specialists. Ningbo Longerfa Hydraulic Co., Ltd., recognized as a national high-tech enterprise, stands out in the crowded market with its commitment to innovation and excellence in producing a comprehensive range of hydraulic components, including hydraulic valve sets, thread plug valves, and valve blocks. Our state-of-the-art manufacturing process is not just about supplying products; it’s about forging partnerships that drive mutual success. Understanding the unique needs of our clients, we leverage advanced research and development capabilities to tailor our offerings to various applications across industries. By choosing Longerfa as your partner, you gain access to cutting-edge technology and a dedicated team focused on ensuring quality and performance. Our expert engineers work closely with clients to develop customized solutions that enhance operational efficiency and reliability, allowing you to stay competitive in an ever-changing market. At Longerfa, we believe in building lasting relationships that go beyond transactional engagements. We strive to provide exemplary support throughout your projects, ensuring that our products not only meet but exceed your expectations. As we continue to innovate and expand our capabilities, we invite global buyers to partner with us and experience the Longerfa difference—transforming your supply chain into a strategic advantage.

China’s Best-Selling Manufacturing Process Of Valves Factory Application More Than a Supplier - A Partner

| Application Area | Valve Type | Material | Operating Pressure (MPa) | Temperature Range (°C) |

|---|---|---|---|---|

| Oil & Gas | Ball Valve | Stainless Steel | 32 | -40 to 150 |

| Water Treatment | Gate Valve | Ductile Iron | 16 | 0 to 80 |

| Chemical Processing | Butterfly Valve | Polypropylene | 10 | -20 to 100 |

| Power Generation | Check Valve | Carbon Steel | 30 | -10 to 300 |

| Pharmaceutical | Diaphragm Valve | PTFE | 6 | -20 to 120 |

Trending Manufacturing Process Of Valves Factory Where Innovation Meets 2025 Market Leader

M

Michael Carter

The quality is top-notch! Additionally, the after-sales service was quick and reliable, which added to my confidence in this purchase.

10 June 2025

J

Jessica Brown

The product has proven to be durable and reliable. The customer service staff were supportive and approachable.

14 June 2025

G

Greg Stewart

Fantastic quality! Their support staff were amazing—truly knowledgeable and ready to assist.

03 July 2025

J

Jacob Wilson

Impressive all around! The quality is great, and the after-sales support was very helpful.

25 May 2025

S

Sophie Martin

Incredible product! The post-purchase assistance from their support team was highly professional.

19 May 2025

H

Hailey Allen

I’m thoroughly impressed! The quality is remarkable, and the service team was friendly.

03 July 2025