Valves Manufacturing Process: Insights from Leading China Manufacturers

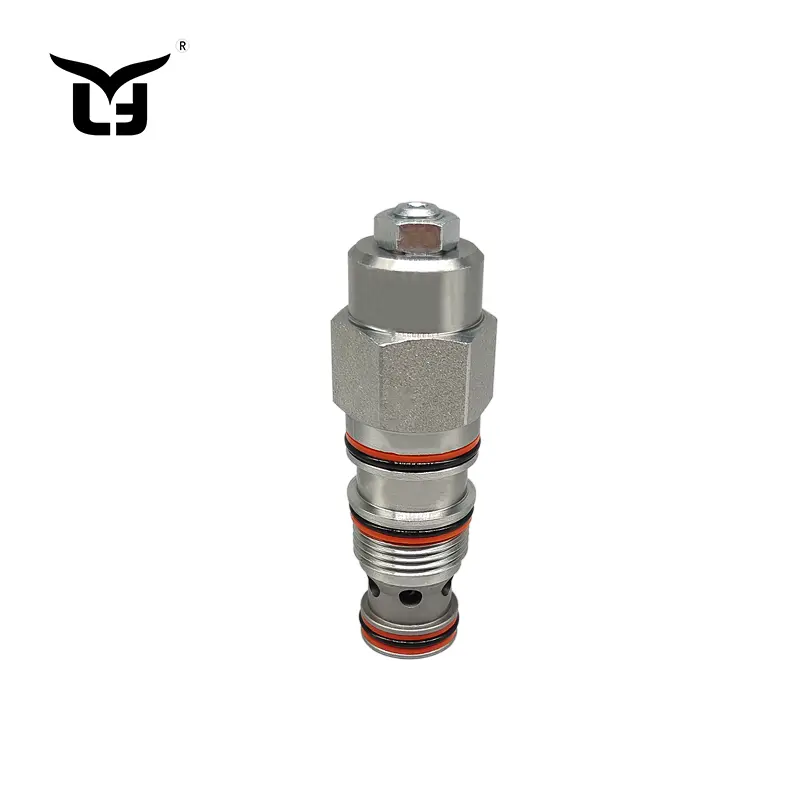

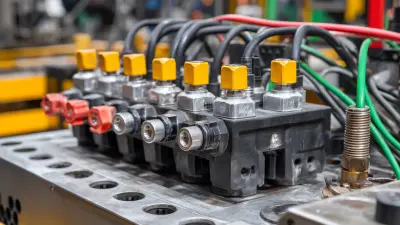

Ningbo Longerfa Hydraulic Co., Ltd. is a leader in precision manufacturing high-quality valves tailored to meet the diverse demands of various industries. Our advanced manufacturing processes guarantee that each valve is produced with the highest quality standards in mind, merging modern technology with expert craftsmanship. From design to final inspection, every phase of production is carefully executed to ensure exceptional durability and performance. Utilizing premium materials and innovative techniques, including CNC machining and advanced surface treatments, we enhance the reliability and longevity of our products. Our extensive product line features various valves, such as ball valves, gate valves, and check valves, suitable for applications across the oil and gas, chemical processing, and water treatment sectors. Committed to innovation and customer satisfaction, we strive to exceed expectations, ensuring that quality and reliability remain at the core of what we do. Rely on Ningbo Longerfa Hydraulic Co., Ltd. for all your valve manufacturing needs.Why Manufacturing Process Of Valves Is The Best Manufacturers You Can Rely On

In today's fast-paced industrial landscape, manufacturers are constantly seeking reliable partners to ensure the efficiency and durability of their products. Ningbo Longerfa Hydraulic Co., Ltd. stands out as a national high-tech enterprise specializing in the research and development, production, and supply of Hydraulic Valve sets, hydraulic thread plug valves, hydraulic valve blocks, and various other hydraulic components. The company has built a reputation for excellence, making it an ideal choice for global buyers looking for high-quality hydraulic solutions. The manufacturing process at Ningbo Longerfa is meticulously designed to uphold the highest standards of quality and precision. Each stage, from material selection to final inspection, is executed with rigorous attention to detail and advanced technological integration. This commitment to quality not only ensures the reliability of our products but also significantly reduces maintenance costs and downtime for our customers. By investing in state-of-the-art manufacturing technologies and continuous improvement practices, we have positioned ourselves as a leader in the hydraulic components industry. Moreover, our team of skilled engineers and designers is dedicated to custom solutions that meet diverse application needs. Whether you require standard hydraulic valves or tailored products, Ningbo Longerfa Hydraulic Co., Ltd. is prepared to deliver exceptional results. When you choose us as your manufacturing partner, you can rely on our expertise, innovative approach, and unwavering commitment to customer satisfaction. Let us support your projects with the precision and reliability that only a high-tech enterprise can offer.

Why Manufacturing Process Of Valves Is The Best Manufacturers You Can Rely On

| Criteria | Description | Importance | Example Manufacturing Standards |

|---|---|---|---|

| Material Quality | High-grade materials ensure durability and reliability in performance. | Critical for safety and longevity of the valves. | ASTM A216, ASTM A352 |

| Manufacturing Precision | Advanced machining techniques are used for tight tolerances. | Ensures optimal performance and minimal leakage. | CNC Machining Standards |

| Testing Procedures | Comprehensive testing for pressure and flow performance. | Verifies integrity and functionality under real conditions. | API 598, ISO 5208 |

| Quality Assurance | Regular audits and inspections to meet quality standards. | Ensures continuous adherence to industry standards. | ISO 9001 Certification |

| Research & Development | Innovation in design and new technologies are implemented. | Improves efficiency and reduces costs. | CAD Modeling, Finite Element Analysis |

Curated Selection of Manufacturing Process Of Valves Trusted by Pros Delivers Unmatched Quality

D

David Wilson

Excellent quality! The post-purchase support was exceptional, with knowledgeable staff willing to assist.

30 June 2025

P

Patrick Wright

Impressive quality! The customer service was quick to assist and knowledgeable about the product.

25 June 2025

G

Greg Stewart

Fantastic quality! Their support staff were amazing—truly knowledgeable and ready to assist.

03 July 2025

L

Logan Taylor

Very happy with my purchase! The quality is excellent, and their support staff were superb.

08 June 2025

O

Owen Robinson

Top-notch product! The after-sales support was reliable and greatly appreciated.

04 June 2025

E

Emma Hernandez

I absolutely love this item! The care shown by customer service made my experience even better.

21 May 2025