OEM Inline Solenoid Valve for Factories | Reliable and Efficient Solutions

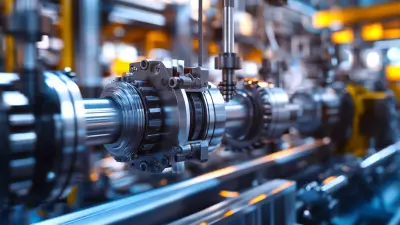

The In Line Solenoid Valve from Ningbo Longerfa Hydraulic Co., Ltd. is engineered for optimal fluid flow control across diverse applications. Crafted for durability, this valve offers reliable performance in challenging environments, thanks to its robust construction. Its compact design facilitates installation in confined spaces without compromising effectiveness. Featuring advanced electromagnetic technology, the valve ensures quick response times and precise operation. Ideal for both automated and manual systems, it significantly boosts the efficiency of hydraulic and pneumatic circuits. Made from high-quality, corrosion-resistant materials, it promises long-lasting, dependable operation. With the capability to support various fluid types and customizable specifications, this In Line Solenoid Valve meets specific industrial requirements, reflecting Ningbo Longerfa Hydraulic Co., Ltd.’s commitment to quality and innovation.Must-Know Tips For In Line Solenoid Valve From Concept to Delivery Custom Solutions,

In today's competitive market, understanding the essentials of custom solutions for inline solenoid valves is crucial. At Ningbo Longerfa Hydraulic Co., Ltd., we specialize in manufacturing high-quality hydraulic components, including advanced solenoid valves tailored for diverse applications. From initial concept to final delivery, our expertise as a national high-tech enterprise ensures that you receive not only a product but a complete solution tailored to your requirements. When considering custom inline solenoid valves, it is important to focus on your specific needs. Our team employs rigorous research and development practices to design valves that meet industry standards and exceed client expectations. We emphasize collaboration with our global partners to fine-tune designs, ensuring optimal performance in various environments. By understanding your unique applications, we can deliver tailored hydraulic solutions that enhance efficiency and productivity. Additionally, we pride ourselves on our commitment to quality and reliability. Every step of our production process adheres to stringent quality control measures, ensuring that your solenoid valves are both durable and high-performing. Trust in Ningbo Longerfa Hydraulic Co., Ltd. for your inline solenoid valve needs, and experience a seamless journey from concept to delivery, all while benefiting from our cutting-edge technology and customer-centric approach.

Must-Know Tips For In Line Solenoid Valve From Concept to Delivery Custom Solutions

| Feature | Description | Importance | Customization Options |

|---|---|---|---|

| Material Selection | The materials used in solenoid valves affect durability and suitability for specific applications. | Critical for performance in diverse environments. | Options include brass, stainless steel, and plastic. |

| Voltage Rating | Valves are designed to operate at specific voltage levels, affecting compatibility with control systems. | Essential for ensuring reliable operation and safety. | Custom voltages available upon request. |

| Flow Rate | Indicates the volume of fluid the valve can control, which is critical for application efficiency. | Determines the valve's applicability in various systems. | Custom flow rates can be engineered to fit specific needs. |

| Pressure Rating | Indicates the maximum pressure the valve can handle, influencing safety and usage in systems. | Vital for preventing failure in high-pressure applications. | Options for high and low-pressure variants available. |

| Mounting Options | Different mounting configurations allow the valve to fit various installation scenarios. | Critical for installation flexibility and space management. | Customized mounting styles can be designed. |

Top-Rated In Line Solenoid Valve Your End-to-End Solution More Than a Supplier - A Partner

R

Robert White

I’m highly impressed by the product quality. Their after-sales service team was professional and ensured I was happy with my purchase.

18 June 2025

S

Sophie Martinez

This is definitely worth every penny! The customer service team displayed exceptional patience and expertise.

29 June 2025

P

Patrick Wright

Impressive quality! The customer service was quick to assist and knowledgeable about the product.

25 June 2025

S

Sarah Wilson

This is an excellent product! The customer service was attentive and provided great insights.

30 June 2025

M

Matthew Anderson

Highly impressive! The quality stands out, and the customer service was truly professional.

28 May 2025

L

Lucy Adams

Very happy with my decision! The quality is impressive, and customer support was outstanding.

08 May 2025