Premium Hydraulic Valve Manifolds | Top Manufacturers in China for Quality Solutions

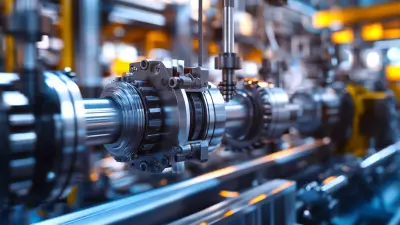

Hydraulic valve manifolds play a crucial role in fluid power systems, enhancing performance and ensuring efficiency across a wide range of applications. At Ningbo Longerfa Hydraulic Co., Ltd., we pride ourselves on being a leading manufacturer in this field, committed to providing high-quality solutions tailored to meet our customers' requirements. Our hydraulic valve manifolds are engineered for durability and precision, utilizing advanced technology to enhance reliability and operational effectiveness. We offer customizable options suitable for various hydraulic systems, ranging from basic designs to intricate configurations. Crafted from premium materials, our products exhibit excellent resistance to wear and tear, facilitating effective fluid transfer and control in a variety of environments. As a trusted partner in hydraulic solutions, we blend innovation with extensive industry expertise, serving sectors such as construction, automotive, and manufacturing. Experience outstanding performance and unparalleled reliability with our expertly designed hydraulic valve manifolds, crafted to meet and surpass industry standards.Best Methods To Hydraulic Valve Manifold Manufacturers Factory-Direct Excellence Guarantees Peak Performance

When it comes to sourcing hydraulic valves and components, partnering with a reliable manufacturer can significantly impact your operations. At Ningbo Longerfa Hydraulic Co., Ltd., we pride ourselves on being a national high-tech enterprise dedicated to the research, development, and production of a wide array of hydraulic products. Our product lineup includes hydraulic valve sets, hydraulic thread plug valves, and hydraulic valve blocks, all designed to ensure peak performance in diverse applications. One of the best methods for ensuring excellence in hydraulic valve systems is to go factory-direct. By collaborating directly with manufacturers like Longerfa, you benefit from reduced lead times and enhanced communication. Our team of experienced engineers is committed to delivering superior quality products, backed by rigorous testing and validation processes. This direct partnership not only guarantees the integrity of your hydraulic systems but also provides transparency throughout the purchasing process. In an ever-evolving market, we understand the importance of reliability and innovation. Our dedication to research and development ensures that we stay at the forefront of hydraulic technology, catering to the unique needs of global procurement. By choosing Ningbo Longerfa Hydraulic Co., Ltd., you are not only investing in high-quality hydraulic solutions but also in a partnership that prioritizes excellence and customer satisfaction. Explore our offerings and discover how we can enhance your hydraulic operations today!

Best Methods To Hydraulic Valve Manifold Manufacturers Factory-Direct Excellence Guarantees Peak Performance

| Dimension | Performance Indicator | Value | Remarks |

|---|---|---|---|

| Flow Rate (L/min) | Max | 100 | Optimal for high-speed applications |

| Operating Pressure (Bar) | Max | 350 | Suitable for heavy machinery |

| Weight (kg) | Average | 25 | Lightweight for easy installation |

| Temperature Range (°C) | Operating | -20 to 80 | Suitable for various environments |

| Material Quality | Type | Steel | Durable and corrosion-resistant |

The Secret to Hydraulic Valve Manifold Manufacturers Service Backed by Expertise Where Service Meets Innovation

A

Alice Green

A fantastic item! The after-sales service team were well-trained and very helpful with everything I needed.

08 June 2025

V

Vanessa Lewis

This product is amazing! Their follow-up service showcased a deep knowledge and commitment to customer satisfaction.

08 May 2025

C

Chloe Brown

Top quality! The after-sales team was efficient and very professional in their approach.

12 May 2025

J

Jacob Wilson

Impressive all around! The quality is great, and the after-sales support was very helpful.

25 May 2025

C

Carter Gray

Great quality and fast service! The customer care staff were very helpful.

30 May 2025

A

Aaron James

Top quality! The support team offered valuable insights and service post-purchase.

05 May 2025