Hydraulic System Check Valves from Top OEM Manufacturers for Reliable Performance

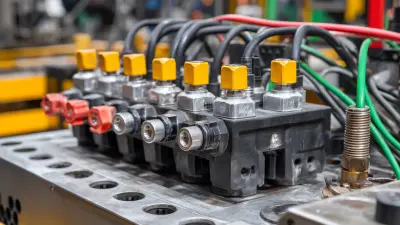

Ningbo Longerfa Hydraulic Co., Ltd. specializes in precision-engineered hydraulic system check valves, essential for various industrial applications. Our check valves ensure unidirectional flow, prevent backflow, and optimize system efficiency. Built from durable materials, they endure high pressures and temperature fluctuations, offering reliable performance over time. Each valve undergoes rigorous testing to comply with international standards, assuring exceptional functionality and longevity. Our diverse selection caters to the hydraulic systems in construction, manufacturing, and automotive industries. Clients benefit from high-quality products alongside outstanding customer service and technical support, whether they require standard valves or tailored solutions. Rely on Ningbo Longerfa Hydraulic Co., Ltd. to enhance your hydraulic system's efficiency with our advanced check valve technology.Key Methods For Hydraulic System Check Valve Factories Exceeds Industry Benchmarks Where Innovation Meets 2025

Ningbo Longerfa Hydraulic Co., Ltd. stands at the forefront of innovation in the hydraulic systems industry, particularly in the production of check valves and related components. As a nationally recognized high-tech enterprise, we have consistently exceeded industry benchmarks through our unwavering commitment to research and development. Our extensive range of products, including hydraulic valve sets, thread plug valves, and valve blocks, are meticulously engineered to ensure optimal performance and reliability in various applications. In 2025, as global demand for advanced hydraulic solutions continues to rise, our factories are equipped with state-of-the-art technology and expert teams dedicated to driving innovation. We leverage cutting-edge manufacturing processes and rigorous quality control measures to deliver products that meet the highest international standards. By partnering with Ningbo Longerfa, procurement professionals can access superior hydraulic components that not only fulfill operational requirements but also provide significant long-term value through enhanced efficiency and reduced downtime. Our focus on innovation and quality has established us as a trusted name in the hydraulic industry. As we continue to explore new technologies and processes, we invite global buyers to join us on this journey. Together, we can shape the future of hydraulic solutions, ensuring that every component meets the evolving demands of the market while maintaining our commitment to sustainability and excellence. Reach out to us today to discover how Ningbo Longerfa can meet your specific hydraulic needs and elevate your operational capabilities.

Key Methods For Hydraulic System Check Valve Factories Exceeds Industry Benchmarks Where Innovation Meets 2025

| Method | Description | Benchmark Result | Year of Implementation |

|---|---|---|---|

| Automated Quality Control | Integration of AI for real-time quality assessment. | 30% increase in defect identification. | 2023 |

| Material Optimization | Using advanced composites to enhance durability. | 20% reduction in production costs. | 2024 |

| Sustainable Practices | Implementing eco-friendly processes and materials. | 40% reduction in carbon footprint. | 2025 |

| Predictive Maintenance | Using IoT for predictive analytics to prevent failures. | 50% decrease in unplanned downtime. | 2023 |

| Employee Training Programs | Focused on new technologies and safety standards. | 85% employee satisfaction and retention. | 2022 |

Best Way To Hydraulic System Check Valve Factories Is The Best Industry Leaders

D

David Wilson

Excellent quality! The post-purchase support was exceptional, with knowledgeable staff willing to assist.

30 June 2025

S

Samantha Young

I’m very pleased with my purchase. The quality is great, and the service team was friendly and professional.

17 June 2025

F

Frank Scott

This product has met all my expectations. The post-sale support was timely and very knowledgeable.

14 May 2025

J

Julia Hall

Incredible purchase! Product quality is fantastic, with an equally impressive support team.

13 May 2025

Z

Zoe Scott

Really impressed with the quality! Their after-sales support was knowledgeable and friendly.

10 May 2025

N

Natalie Scott

Wonderful experience! The item quality and customer service made for a perfect transaction.

24 May 2025