Leading Hydraulic Return Valve Manufacturers | Quality OEM Solutions for Your Needs

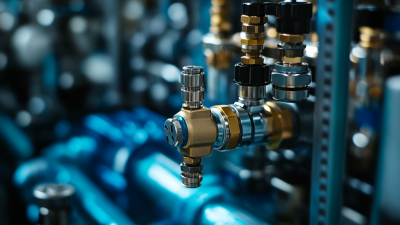

Ningbo Longerfa Hydraulic Co., Ltd. focuses on manufacturing high-quality hydraulic return valves that improve the efficiency and performance of hydraulic systems. Our precision-engineered valves facilitate optimal flow control, allowing hydraulic fluid to return smoothly to the reservoir while minimizing pressure drops. Constructed from premium materials, these valves are designed for durability and reliability in challenging environments. They are well-suited for various applications, such as construction machinery, automotive systems, and industrial equipment, delivering exceptional sealing and minimal leakage. With a commitment to innovation, Longerfa Hydraulic collaborates closely with clients to provide tailored solutions that address specific requirements. Count on Ningbo Longerfa Hydraulic Co., Ltd. for your hydraulic return valve needs, enhancing the efficiency of your hydraulic applications.Practical Strategies for Hydraulic Return Valve Manufacturers Service Now Trending

In the rapidly evolving landscape of hydraulic components, hydraulic return valve manufacturers like Ningbo Longerfa Hydraulic Co., Ltd. are at the forefront of providing innovative solutions. As a national high-tech enterprise, Longerfa specializes in the research and development of a diverse range of hydraulic products, including hydraulic valve sets, hydraulic thread plug valves, and valve blocks. This expertise allows them to stay ahead of emerging trends while meeting the specific demands of global buyers. To effectively serve the international market, it is crucial for manufacturers to adopt practical strategies that enhance product reliability and customer satisfaction. For instance, implementing rigorous quality control processes and leveraging advanced manufacturing technologies can significantly improve product performance. Additionally, offering customized solutions tailored to the unique requirements of clients can foster stronger relationships and encourage repeat business. As global procurement trends shift towards sustainability, incorporating eco-friendly practices in production not only meets market demands but also sets a brand apart. Investing in research and development is another key strategy for staying relevant in the competitive hydraulic industry. By continually innovating and diversifying product lines, manufacturers can address the changing needs of various sectors, from construction to automotive. In conclusion, by focusing on quality, customization, and innovation, hydraulic return valve manufacturers can effectively position themselves as leaders in the market, ensuring sustainable growth and success in the global arena.

Practical Strategies for Hydraulic Return Valve Manufacturers Service Now Trending

| Strategy | Description | Benefits | Implementation Timeframe | Estimated Cost |

|---|---|---|---|---|

| Regular Maintenance | Scheduled inspections and maintenance to prevent failures. | Increased lifespan of valves and reduced downtime. | Ongoing | $500 - $1000 per quarter |

| Remote Monitoring | Using IoT devices to monitor valve performance in real-time. | Early detection of issues and improved reliability. | 3-6 months | $3000 - $5000 initial setup |

| Training Programs | Training staff on proper handling and maintenance of valves. | Reduced risk of user error and enhanced operational safety. | 1-2 months | $2000 for sessions |

| Automated Testing | Implementing automated testing to ensure functionality. | Consistent quality control and faster turnaround times. | 4-8 months | $10,000 - $20,000 |

| Feedback Loops | Establishing channels for customer feedback on valve performance. | Improved products and customer satisfaction. | Ongoing | $500 for setup |

Best Options For Hydraulic Return Valve Manufacturers Your Trusted OEM Partner Leads the Global Market

D

David Wilson

Excellent quality! The post-purchase support was exceptional, with knowledgeable staff willing to assist.

30 June 2025

S

Samantha Young

I’m very pleased with my purchase. The quality is great, and the service team was friendly and professional.

17 June 2025

I

Isabella Lee

Thrilled with my new purchase! The product quality and customer assistance are exceptional.

07 May 2025

E

Emma Hernandez

I absolutely love this item! The care shown by customer service made my experience even better.

21 May 2025

J

Jack Lee

What a great purchase! The product quality is impressive, and the support team was very accommodating.

05 June 2025

L

Luna Rivera

Absolutely satisfied with my purchase! The quality speaks for itself, and customer service was great.

11 June 2025