Leading Hydraulic Manifold Diagram Manufacturers in China | High-Quality Solutions

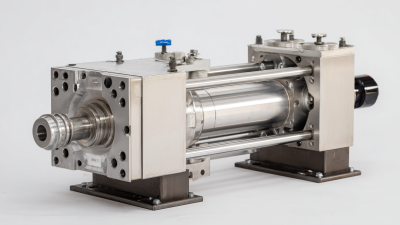

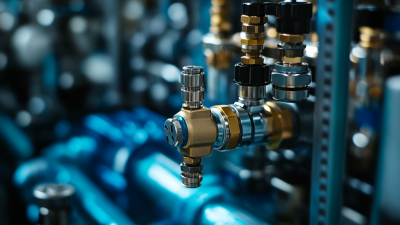

Ningbo Longerfa Hydraulic Co., Ltd. specializes in high-quality hydraulic manifold diagrams designed to optimize fluid distribution and improve system efficiency. With extensive experience in the hydraulic industry, we create customizable solutions for a variety of applications. Our hydraulic manifolds are precisely engineered for reliable performance under high pressure and challenging conditions. Each diagram features a clear and intuitive layout, making installation and maintenance straightforward, which helps minimize downtime. Committed to durability and longevity, we utilize advanced materials and innovative manufacturing techniques. At Ningbo Longerfa, we prioritize customer satisfaction and collaborate closely with clients to develop tailored solutions that fulfill their specific needs. Whether for industrial machinery, mobile equipment, or any hydraulic system, our hydraulic manifolds ensure superior functionality and performance, contributing to the seamless operation of your projects.10 tips Hydraulic Manifold Diagram Manufacturers From Concept to Delivery Exceeds Industry Benchmarks

In the competitive landscape of hydraulic components manufacturing, Ningbo Longerfa Hydraulic Co., Ltd. stands out as a national high-tech enterprise dedicated to excellence. Our expertise extends from the research and development of hydraulic valve sets to the production of hydraulic thread plug valves, valve blocks, and a variety of hydraulic products. We understand that global buyers are not just looking for products; they seek reliable partners who can deliver innovative solutions that meet and exceed industry benchmarks. Our comprehensive approach to manufacturing hydraulic manifold diagrams emphasizes quality at every stage—from concept design to final delivery. We implement rigorous testing protocols and advanced technologies to ensure every product meets international standards, providing our clients with confidence in our solutions. Collaboration with our skilled engineers enables us to customize products that cater to specific project requirements, thus enhancing operational efficiency and functionality. By choosing Ningbo Longerfa as your hydraulic component supplier, you're not only gaining access to high-quality products but also a partnership committed to driving your success. We pride ourselves on our ability to adapt swiftly to market demands, ensuring timely delivery without compromising quality. Join us in redefining industry standards and discover the difference of working with a manufacturer that prioritizes your needs above all.

10 Tips Hydraulic Manifold Diagram Manufacturers From Concept to Delivery Exceeds Industry Benchmarks

| Tip Number | Tip Description | Expected Outcome | Benchmark Metric |

|---|---|---|---|

| 1 | Utilize Advanced CAD Software | Improved design accuracy | >90% Design Accuracy |

| 2 | Implement Simulation Tools | Reduced prototype costs | >30% Cost Reduction |

| 3 | Focus on Modular Designs | Easier future upgrades | >25% Upgrade Efficiency |

| 4 | Standardize Components | Streamlined inventory management | >15% Inventory Reduction |

| 5 | Enhance Communication with Clients | Increased customer satisfaction | >95% Client Satisfaction |

| 6 | Adopt Lean Manufacturing Principles | Enhanced efficiency | >20% Process Efficiency |

| 7 | Use Quality Assurance Processes | Minimized defects | |

| 8 | Maintain Strong Supplier Relationships | Consistent material quality | >90% Supplier Reliability |

| 9 | Invest in Employee Training | Improved workforce skills | >85% Employee Competency |

| 10 | Embrace New Technologies | Innovative solutions | >30% Technology Adoption Rate |

How To Decide Between Hydraulic Manifold Diagram Manufacturers Trusted by Pros Dominates

P

Patrick Wright

Impressive quality! The customer service was quick to assist and knowledgeable about the product.

25 June 2025

A

Alice Green

A fantastic item! The after-sales service team were well-trained and very helpful with everything I needed.

08 June 2025

G

Greg Stewart

Fantastic quality! Their support staff were amazing—truly knowledgeable and ready to assist.

03 July 2025

O

Oliver Brown

High-quality item! Their customer service was incredibly responsive and knowledgeable.

20 May 2025

Z

Zoe Scott

Really impressed with the quality! Their after-sales support was knowledgeable and friendly.

10 May 2025

A

Aaron James

Top quality! The support team offered valuable insights and service post-purchase.

05 May 2025