Top High-Quality Hydraulic Check Valve Types from Leading Manufacturers

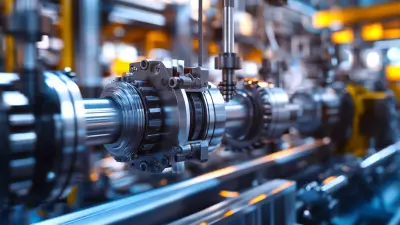

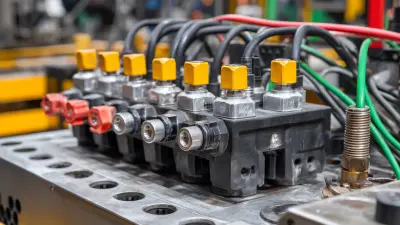

Ningbo Longerfa Hydraulic Co., Ltd. is a leader in manufacturing high-quality hydraulic check valves that enhance the efficiency and reliability of hydraulic systems in various industries. Our diverse selection of check valves prevents backflow while ensuring fluid flows in a single direction, safeguarding equipment and optimizing performance. We offer a range of designs including ball, swing, and diaphragm check valves, all made from durable materials that endure harsh conditions and high pressure. Our products are precisely engineered for exceptional sealing capabilities and an extended lifespan, making them perfect for applications in construction, agriculture, and industrial machinery. With a commitment to innovation and excellence, we utilize advanced manufacturing techniques to ensure our hydraulic check valves comply with the highest industry standards, providing reliable performance and exceptional service. Experience the difference with our expertly crafted hydraulic solutions.Practical Methods To Hydraulic Check Valve Types Manufacturer in 2025 From Concept to Delivery

In 2025, the demand for hydraulic check valves continues to rise, driven by advancements in various industries globally. As a leading manufacturer, Ningbo Longerfa Hydraulic Co., Ltd. specializes in the research, development, and production of a wide range of hydraulic products, including hydraulic valve sets, thread plug valves, valve blocks, and other critical components. Our expertise as a national high-tech enterprise enables us to innovate and deliver practical solutions tailored to meet the specific needs of our global buyers. Understanding the different types of hydraulic check valves is essential for efficient application in fluid systems. In the coming years, we foresee a surge in interest in ball, swing, and diaphragm check valves, each offering distinct benefits suited to various operational demands. Our commitment to quality and precision manufacturing ensures that every product we deliver enhances system performance and reliability. By maintaining stringent quality controls and leveraging advanced technology, we can provide solutions that align with global standards, catering specifically to the requirements of industries ranging from automotive to construction. Partnering with Ningbo Longerfa means gaining access to not just high-quality hydraulic components but also comprehensive support from concept to delivery. Our dedicated team works closely with clients to ensure that the products meet their specific applications, fostering long-lasting relationships built on trust and mutual growth. As we look to the future, our focus remains on innovation and excellence, positioning us as the go-to partner for hydraulic solutions in an ever-evolving market.

Practical Methods To Hydraulic Check Valve Types Manufacturer in 2025 From Concept to Delivery

| Valve Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Application | Delivery Time (Weeks) |

|---|---|---|---|---|---|

| Ball Check Valve | Stainless Steel | 3000 | -20 to 150 | Water, Oil | 6 |

| Spring Check Valve | Brass | 1500 | -10 to 180 | Gas, Oil | 4 |

| Lift Check Valve | Ductile Iron | 2500 | -20 to 200 | Water, Slurry | 8 |

| Dual Plate Check Valve | Carbon Steel | 600 | -40 to 250 | Wastewater, Oil | 7 |

| Silent Check Valve | PVC | 400 | 32 to 140 | Chemical, Water | 5 |

Exploring Hydraulic Check Valve Types Manufacturer From Concept to Delivery Custom Solutions,

M

Michelle Clark

Fantastic item! The after-sales service was helpful, and the representatives were very knowledgeable.

09 June 2025

E

Edward Hall

Great purchase! The product is exceptional, and their customer service was equally impressive.

10 June 2025

V

Vanessa Lewis

This product is amazing! Their follow-up service showcased a deep knowledge and commitment to customer satisfaction.

08 May 2025

J

Joshua Hall

Outstanding quality! The customer service representatives were also very thorough and attentive.

19 June 2025

V

Victoria Martin

I couldn’t be happier with this product! The follow-up service was top-notch and incredibly professional.

21 June 2025

L

Lucas Hill

Top-tier quality and service! Their support staff demonstrated real professionalism.

22 June 2025