High-Quality Valve Manufacturing: OEM Solutions from Trusted Manufacturers

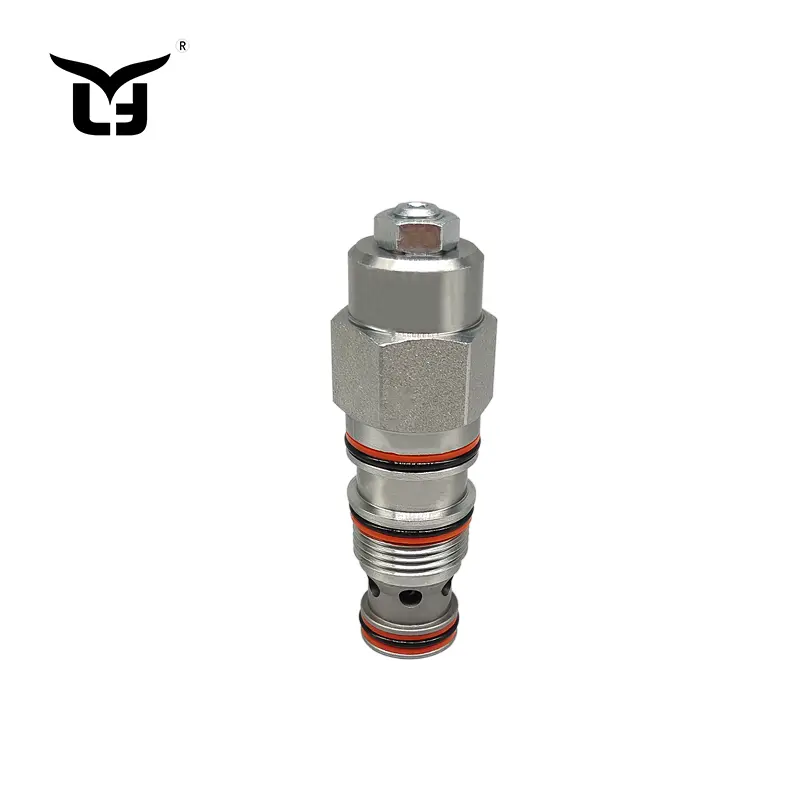

Ningbo Longerfa Hydraulic Co., Ltd. delivers top-tier valve manufacturing with a focus on exceptional quality and precision. Our commitment to advanced production techniques ensures that each valve adheres to the highest industry standards. Utilizing state-of-the-art technology, we produce robust and dependable valves suitable for various applications, including hydraulic systems, fluid control, and automation. Our extensive product range caters to diverse operational requirements, and rigorous quality control guarantees unmatched performance and durability. Customer satisfaction is our priority; we provide customization options and prompt services tailored to client needs. Experience the reliability and efficiency our premium valves bring, and join the community of satisfied clients who benefit from our expertise and dedication to excellence. Partner with us for innovative manufacturing solutions that enhance your business.

Best Methods To High-Quality Manufacturing Of Valves Factory Where Innovation Meets 2025

Best Methods To High-Quality Manufacturing Of Valves Factory Where Innovation Meets 2025

| Method | Description | Advantages | Challenges | Future Potential |

|---|---|---|---|---|

| Additive Manufacturing | 3D printing technologies are used for rapid prototyping and production. | Reduces waste, allows for complex geometries, and shorter lead times. | Material limitations and slower production rates for high volumes. | Innovations in materials could increase scalability. |

| Automation | Integration of robotics and AI for assembly line processes. | Increases efficiency, reduces human error, and improves consistency. | High initial setup costs and workforce displacement concerns. | Continuous advancements in AI can enhance operation flexibility. |

| Lean Manufacturing | Focus on minimizing waste without sacrificing productivity. | Improves efficiency and reduces costs. | Requires cultural change within the organization. | Integration with digital tools can amplify lean benefits. |

| Quality Management Systems | Structured systems that enhance product quality and process reliability. | Standardizes processes and supports compliance with regulations. | Can be inflexible and slow to adapt to changes. | Technology integration enhances data analysis and process improvements. |

| Sustainability Practices | Implementing eco-friendly materials and processes. | Reduces environmental impact and improves brand image. | Potentially higher costs and material availability issues. | Growing consumer demand for sustainable products presents new opportunities. |