High-Quality Ball Valve Principles: OEM Manufacturer's Comprehensive Guide

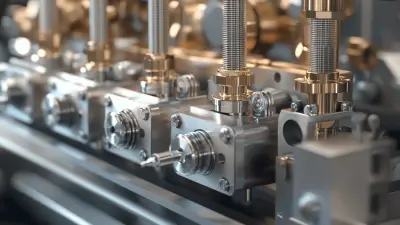

At Ningbo Longerfa Hydraulic Co., Ltd., high-quality ball valves play a crucial role in fluid control systems, ensuring unmatched performance and reliability. Our precision-engineered ball valves operate on a straightforward principle: a hollow, perforated sphere (the ball) rotates within a seat, effectively managing fluid flow. This design guarantees exceptional sealing, minimal pressure drop, and quick shut-off, making our valves suitable for a wide range of applications including water, gas, and oil. Crafted from premium materials, our ball valves are built to endure high pressures and challenging environments, promoting longevity and safety. With various sizes and configurations available, we meet diverse industrial requirements. Rely on Ningbo Longerfa Hydraulic Co., Ltd. for ball valves that enhance operational efficiency and safety, achieving an impressive balance of quality, performance, and affordability tailored to your needs.

How To Pick The Right High-Quality Ball Valve Working Principle Ahead of the Curve Global Reach

How To Pick The Right High-Quality Ball Valve Working Principle Ahead of the Curve Global Reach

| Valve Type | Material | Size (inches) | Pressure Rating (PSI) | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| Floating Ball Valve | Stainless Steel | 1 | 2000 | -20 to 350 | Water, Oil |

| Trunnion Ball Valve | Carbon Steel | 2 | 3000 | -20 to 400 | Gas, Chemicals |

| V-Port Ball Valve | Bronze | 3 | 1500 | -30 to 250 | Flow Control |

| Full Port Ball Valve | PVC | 1.5 | 150 | 32 to 140 | Water Treatment |