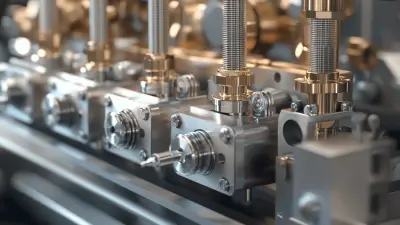

Premium Corrosion Resistant Check Valves from China for Superior Reliability

Ningbo Longerfa Hydraulic Co., Ltd. focuses on the production of high-quality corrosion-resistant check valves, built to perform reliably in challenging environments. These valves ensure exceptional durability, making them ideal for use in chemical processing, marine applications, and wastewater management. Crafted from advanced materials, our corrosion-resistant check valves effectively prevent backflow and offer superior protection against abrasive and caustic fluids. The innovative design features a streamlined flow path that reduces pressure drop and enhances system efficiency. Our commitment to quality and precision in manufacturing aligns with stringent industry standards, resulting in products that exceed customer expectations. Whether in need of a single valve or a bulk order, our dedicated team is ready to provide customized solutions that meet your specific requirements. Experience unparalleled performance and longevity with Ningbo Longerfa Hydraulic Co., Ltd.'s corrosion-resistant check valves, tailored for reliability in demanding conditions.Key Methods For Corrosion Resistant Check Valve Products Supplies the World’s Top Brands Your End-to-End Solution

At Ningbo Longerfa Hydraulic Co., Ltd., we understand that the demand for durable, high-quality hydraulic components is ever-increasing across various industries worldwide. As a professional manufacturer recognized as a national high-tech enterprise, we specialize in the research, development, and production of a comprehensive range of hydraulic products, including our esteemed corrosion-resistant check valves. These valves are meticulously designed to withstand harsh environments, ensuring reliability and longevity for the world’s top brands. Our commitment to innovation and excellence puts us at the forefront of supplying end-to-end solutions tailored for global buyers. Our corrosion-resistant check valves not only prevent backflow but also exhibit outstanding strength against corrosive substances, which is vital for industries such as oil and gas, marine, and chemical processing. By integrating advanced materials and cutting-edge technology in our production process, we ensure that our products meet the highest international standards, making them a perfect fit for diverse applications. Partnering with us means benefiting from our extensive expertise and comprehensive support throughout your procurement journey. We pride ourselves on our ability to deliver customized solutions that meet specific needs, backed by our dedicated customer service team. Let Ningbo Longerfa Hydraulic Co., Ltd. be your trusted supplier for high-quality hydraulic components, guaranteeing performance and durability that you can rely on.

Key Methods For Corrosion Resistant Check Valve Products Supplies the World’s Top Brands Your End-to-End Solution

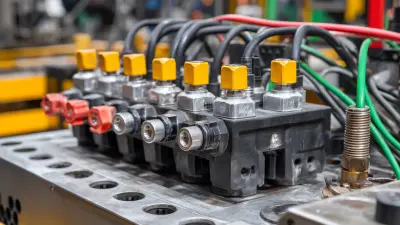

| Method | Corrosion Resistance | Material Used | Applications | Certifications |

|---|---|---|---|---|

| Coating | High | Epoxy, PTFE | Oil & Gas | ISO 9001 |

| Material Selection | Moderate | Stainless Steel, Duplex | Chemical Processing | ASTM |

| Passivation | High | Stainless Steel | Pharmaceuticals | FDA |

| Anodizing | Very High | Aluminum | Aerospace | MIL-SPEC |

| Galvanization | Moderate | Steel | Construction | CE |

Decoding Corrosion Resistant Check Valve Products Winning in 2025 From Concept to Delivery

K

Kevin Perez

Excellent craftsmanship! The follow-up service was superb, showcasing a true commitment to customer satisfaction.

26 June 2025

F

Frank Scott

This product has met all my expectations. The post-sale support was timely and very knowledgeable.

14 May 2025

C

Cynthia Johnson

I truly appreciate the quality and care in customer service. The team was really helpful when I had questions.

16 May 2025

P

Patrick Wright

Impressive quality! The customer service was quick to assist and knowledgeable about the product.

25 June 2025

E

Emma Thompson

Very satisfied with the purchase! The product quality and support team exceeded my expectations.

01 June 2025

G

Gabriel White

Quality exceeded expectations! Their support team was knowledgeable and supportive.

30 May 2025