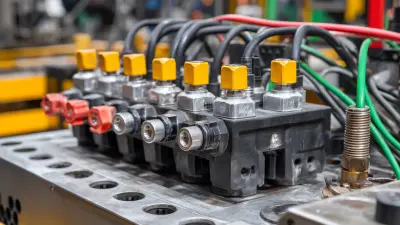

Premium Corrosion Resistant Check Valves from Leading Manufacturers for Optimal Performance

Ningbo Longerfa Hydraulic Co., Ltd. presents an innovative corrosion-resistant check valve designed for reliability and endurance in harsh conditions. Manufactured from high-quality materials, this valve provides superior resistance to corrosive substances, making it suitable for diverse applications in chemical processing, water treatment, and marine environments. The robust design enhances flow efficiency while effectively preventing backflow, which ensures optimal system performance. Precision-engineered components deliver a tight seal, reducing leakage and minimizing maintenance needs. With a strong commitment to quality and innovation, Ningbo Longerfa Hydraulic Co., Ltd. offers a check valve that not only extends the lifespan of hydraulic systems but also improves operational safety. Experience exceptional performance with this advanced valve solution.How To Pick The Right Corrosion Resistant Check Valve Product Where Innovation Meets 2025 Ahead of the Curve

When it comes to selecting the right corrosion-resistant check valve product, especially with the innovation landscape shifting rapidly toward 2025, it's essential to make informed choices that align with your operational needs and sustainability goals. At Ningbo Longerfa Hydraulic Co., Ltd., we pride ourselves on crafting high-quality hydraulic components, including our sophisticated check valve solutions, designed to withstand harsh environments. Our focus on research and development allows us to integrate cutting-edge technology into our products, ensuring reliability and longevity, even in corrosive settings. Global procurement professionals should consider a few key factors when selecting check valves. Firstly, assess the materials used in production—our valves are designed with high-grade alloys and coatings that provide superior resistance to rust and chemical damage. Secondly, review the valve's design and functionality; our innovative designs not only enhance performance but also simplify installation and maintenance. By choosing a product from a recognized high-tech enterprise like Ningbo Longerfa, you ensure compliance with international standards while benefiting from our expertise in hydraulic solutions. Innovation is crucial in staying ahead of the curve. As we approach 2025, the demand for advanced, corrosion-resistant components is expected to grow significantly. At Ningbo Longerfa, we are committed to adapting our products to meet evolving market needs. Collaborating with us means you gain access to state-of-the-art technology and a dedicated team focused on delivering high-quality, durable solutions to enhance your operations. Whether you're in the oil and gas industry, water treatment, or manufacturing, selecting our check valves will ensure you remain competitive and efficient in a challenging marketplace.

How To Pick The Right Corrosion Resistant Check Valve Product Where Innovation Meets 2025 Ahead of the Curve

| Product Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Size (Inches) |

|---|---|---|---|---|

| Swing Check Valve | Stainless Steel | 150 | -20 to 300 | 2 |

| Lift Check Valve | Bronze | 200 | -10 to 250 | 3 |

| Ball Check Valve | PVC | 50 | -5 to 140 | 1.5 |

| Duckbill Check Valve | Silicone | N/A | -50 to 200 | 2 |

| Fail-Safe Check Valve | Carbon Steel | 300 | -20 to 400 | 4 |

Why Professionals Prefer Corrosion Resistant Check Valve Product Sets the Industry Standard Winning in 2025

S

Samantha Young

I’m very pleased with my purchase. The quality is great, and the service team was friendly and professional.

17 June 2025

K

Kimberly Robinson

Fantastic experience all around! The quality of the item and the professionalism of the support staff stood out.

06 May 2025

B

Benjamin White

The product quality is simply exceptional! The follow-up support was remarkably professional.

31 May 2025

E

Emma Hernandez

I absolutely love this item! The care shown by customer service made my experience even better.

21 May 2025

L

Luna Rivera

Absolutely satisfied with my purchase! The quality speaks for itself, and customer service was great.

11 June 2025

E

Ethan Martinez

The product is great! Their after-sales team demonstrated professionalism and care.

12 June 2025