Chinese Hydraulic Valve Types: Trusted Products and Reliable Manufacturers

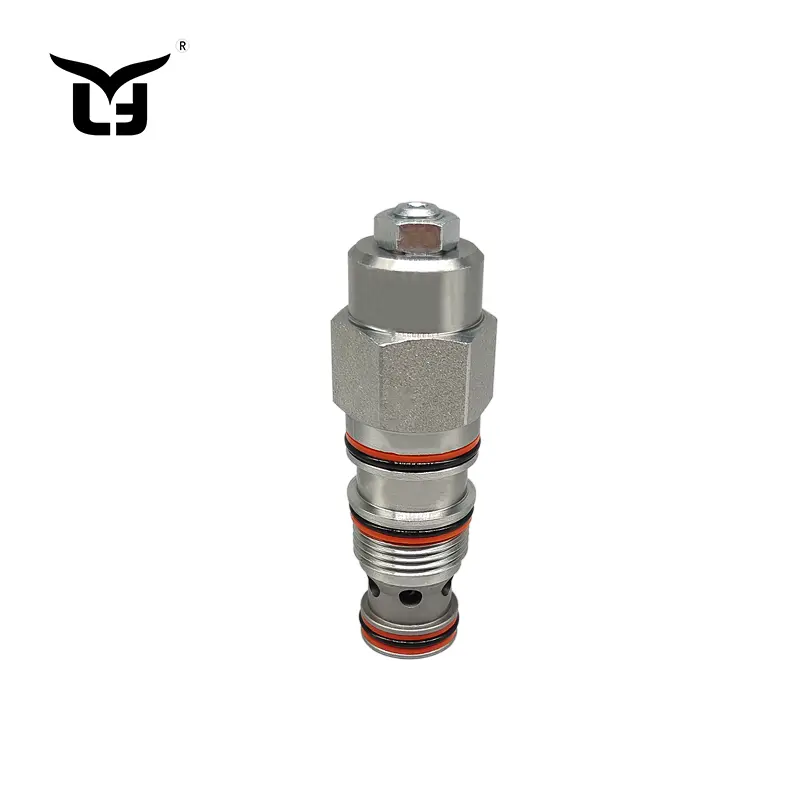

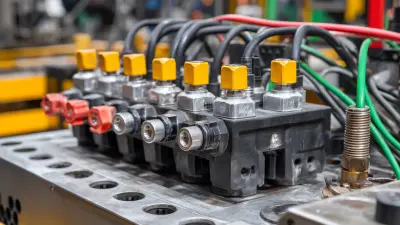

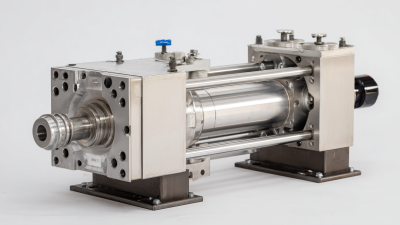

Ningbo Longerfa Hydraulic Co., Ltd. offers a wide selection of high-performance valves for hydraulic systems. Our expertise lies in innovative solutions, providing a variety of valves including pressure relief valves, flow control valves, and directional control valves. Each product is meticulously engineered to enhance efficiency and reliability in industrial applications, capable of withstanding demanding environments to ensure optimal performance and longevity. Employing advanced materials and manufacturing techniques, our valves comply with international quality standards, making them ideal for diverse sectors such as construction, agriculture, and manufacturing. Our experienced engineering team focuses on delivering customized solutions to satisfy your specific hydraulic requirements. Committed to exceptional service and support, Ningbo Longerfa Hydraulic Co., Ltd. is your trusted partner for hydraulic valve solutions, promising unmatched quality and innovation.Tips & Tricks for China Types Of Valves In Hydraulic System Factory Industry Leaders

In the competitive landscape of the hydraulic system industry, understanding the various types of valves and their applications is crucial for maximizing efficiency and performance. At Ningbo Longerfa Hydraulic Co., Ltd., we specialize in the research and development of hydraulic valve solutions, including hydraulic valve sets, thread plug valves, and valve blocks. As a national high-tech enterprise, our commitment to innovation and quality positions us as industry leaders, providing essential insights for global buyers navigating this complex market. When selecting valves for hydraulic systems, it's important to consider factors such as pressure ratings, flow capacity, and compatibility with different fluids. For instance, our hydraulic thread plug valves are designed for high-pressure applications, ensuring leak-free connections and enhanced safety. Additionally, hydraulic valve blocks facilitate the control of multiple cylinders or actuators, offering streamlined operations in demanding environments. Our expert team is dedicated to guiding procurement professionals through product specifications, ensuring they choose the right solutions to meet their operational needs. Moreover, staying updated with the latest trends and technologies in valve manufacturing can enhance decision-making. Embracing advancements, such as smart valve technology and improved materials, can significantly boost the reliability and efficiency of hydraulic systems. By partnering with Ningbo Longerfa Hydraulic Co., Ltd., global buyers will gain access to high-quality products, innovative designs, and unparalleled customer support to drive their success in the hydraulic industry.

Tips & Tricks for China Types Of Valves In Hydraulic System Factory Industry Leaders

| Valve Type | Common Applications | Advantages | Disadvantages | Maintenance Tips |

|---|---|---|---|---|

| Ball Valve | Oil and gas applications, chemical industry | Quick opening and closing, low friction | Limited flow capacity, seat wear | Regularly check seals, lubricate moving parts |

| Gate Valve | Water supply, oil and gas distribution | Minimal flow resistance, good seal | Slow operation, space requirement | Check for corrosion, ensure proper alignment |

| Check Valve | Pipelines to prevent backflow | Simple design, protects equipment | Can be noisy, pressure drop | Inspect frequently, replace worn parts |

| Globe Valve | Flow regulation in oil, gas, and water systems | Excellent throttling capability | Higher pressure drop, slower opening | Keep the stem lubricated, inspect seating surfaces |

| Solenoid Valve | Automated systems, irrigation | Fast response time, low power consumption | Susceptible to wear, requires electrical supply | Test frequently, check for electrical faults |

why choose China Types Of Valves In Hydraulic System in 2025 Ahead of the Curve

D

David Wilson

Excellent quality! The post-purchase support was exceptional, with knowledgeable staff willing to assist.

30 June 2025

N

Nancy Hall

The product is of outstanding quality. Their customer service made a difference, handling my queries with expertise and care.

09 June 2025

B

Brittany Wood

Loving my new product! The support staff provided excellent assistance and were very professional throughout.

01 July 2025

R

Rachel Scott

Superior product! The after-sales team was professional, friendly, and very reliable.

13 June 2025

I

Isabella Lee

Thrilled with my new purchase! The product quality and customer assistance are exceptional.

07 May 2025

C

Carter Gray

Great quality and fast service! The customer care staff were very helpful.

30 May 2025